What Is Aramid Flame Retardant Reflective Tape?

2025-04-08

Ysmlite

ysmlite.com

Aramid flame retardant reflective tape is a special safety material that combines high reflective performance with excellent flame retardant properties. It is widely used in high-risk industries such as firefighting, mining, and electricity. This tape uses aramid fiber as the base material and achieves high reflectivity through micro-prismatic reflection technology while maintaining excellent high temperature resistance and flame retardant properties. High-quality aramid flame retardant reflective tape can remain stable in high temperature environments above 200°C, and the reflectivity can reach 500 cd/lx/m², providing all-round safety protection for workers.

| Table of Contents | |

| Chapter | Content |

| 1. What is aramid flame retardant reflective tape? How does it work? | Detailed explanation of the composition and working principle of aramid flame retardant reflective tape |

| 2. What are the characteristics of aramid fiber and its application in flame retardant reflective tape? | Introduce the characteristics and advantages of aramid fiber |

| 3. Which industries need to use aramid flame retardant reflective tape the most? Why? | Analyze the demand for aramid flame retardant reflective tape in different industries |

| 4. How to choose the aramid flame retardant reflective tape that best suits your needs? | Provide practical suggestions for choosing the right flame retardant reflective tape |

| 5. What is engineering grade aramid flame retardant reflective tape? What is the difference with ordinary grade? | Explain different grades of aramid flame retardant reflective tape and their differences |

| 6. How to properly install and maintain aramid flame retardant reflective tape to extend its service life? | Share practical tips for installation and maintenance |

| 7. Conclusion | Summarize the value and future development of aramid flame retardant reflective tape |

What is aramid flame retardant reflective tape? How does it work?

Aramid fire retardant reflective tape is a special safety material that combines high reflective properties with excellent flame retardant properties. It usually consists of several key layers: a base fabric layer based on aramid, a glue layer, an aluminum reflective layer, and a high-refractive glass bead layer. Among them, part of the sphere of each glass bead is embedded in the aluminum reflective layer to form an efficient reflective system.

The working principle of this tape is based on micro-prismatic reflection technology. When light hits the surface of the tape, the high-refractive glass microbeads refract the light onto the internal aluminum reflective layer and then reflect it back in the direction of the light source. This structure enables aramid flame retardant reflective tape to achieve a reflectivity of up to 500 cd/lx/m², which is much higher than the industry standard of 350-450 cd/lx/m², ensuring excellent visibility in low-light environments.

The base material of aramid flame retardant reflective tape is mainly 100% aramid fiber or 100% cotton with flame retardant treatment. Both materials have excellent high temperature resistance and flame retardant properties, allowing the entire tape system to maintain high reflective performance while maintaining structural integrity in extremely high temperature environments, without melting or producing toxic gases, thereby providing users with a higher level of safety protection.

It is worth noting that flame retardant reflective tapes from professional manufacturers such as YSM have passed a number of international authoritative certifications, such as EN 20471 Class II standard, ANSI/ISEA 107-2020 and Oeko Tex 100. These certifications not only prove the product's excellent performance in reflective performance and environmental protection, but also ensure the product's compliance worldwide.

What are the characteristics of aramid fiber and its application in flame-retardant reflective tape?

Aramid fiber, full name "aromatic polyamide fiber", is a long-chain synthetic polyamide fiber with more than 85% of amide bonds directly connected to the benzene ring. This special molecular structure gives aramid a number of excellent properties, making it an ideal choice for making high-performance safety materials.

Aramid fiber is mainly divided into two types: meta-aramid and para-aramid. Meta-aramid has excellent thermal stability, flame retardancy, electrical insulation, chemical stability and radiation resistance. It can be used for a long time at a high temperature of 200°C without aging, and the limiting oxygen index value (LOI) is greater than 28%. It will not spontaneously combust, melt, or produce molten droplets in the air, and it will extinguish itself after leaving the flame. Para-aramid is known for its high specific strength and high specific modulus. Its tensile strength is 6 times that of steel wire. It is called "bulletproof fiber" and it does not decompose or melt at a high temperature of 560°C.

In flame-retardant reflective tape, the application of aramid fiber is mainly reflected in the substrate layer. Compared with traditional polyester or nylon substrates, aramid substrates have the following advantages:

- Excellent high temperature resistance: Aramid substrates can withstand high temperature environments above 200°C and are suitable for high temperature workplaces such as firefighting and smelting.

- Intrinsic flame retardant properties: Aramid itself is flame retardant and does not require additional flame retardant treatment, and can maintain structural stability in extreme environments.

- High strength and durability: The high strength of aramid makes the flame retardant reflective tape have a longer service life and maintain good performance even in harsh environments.

- Excellent chemical stability: Aramid is resistant to a variety of chemicals, allowing the tape to maintain stable performance in chemical environments.

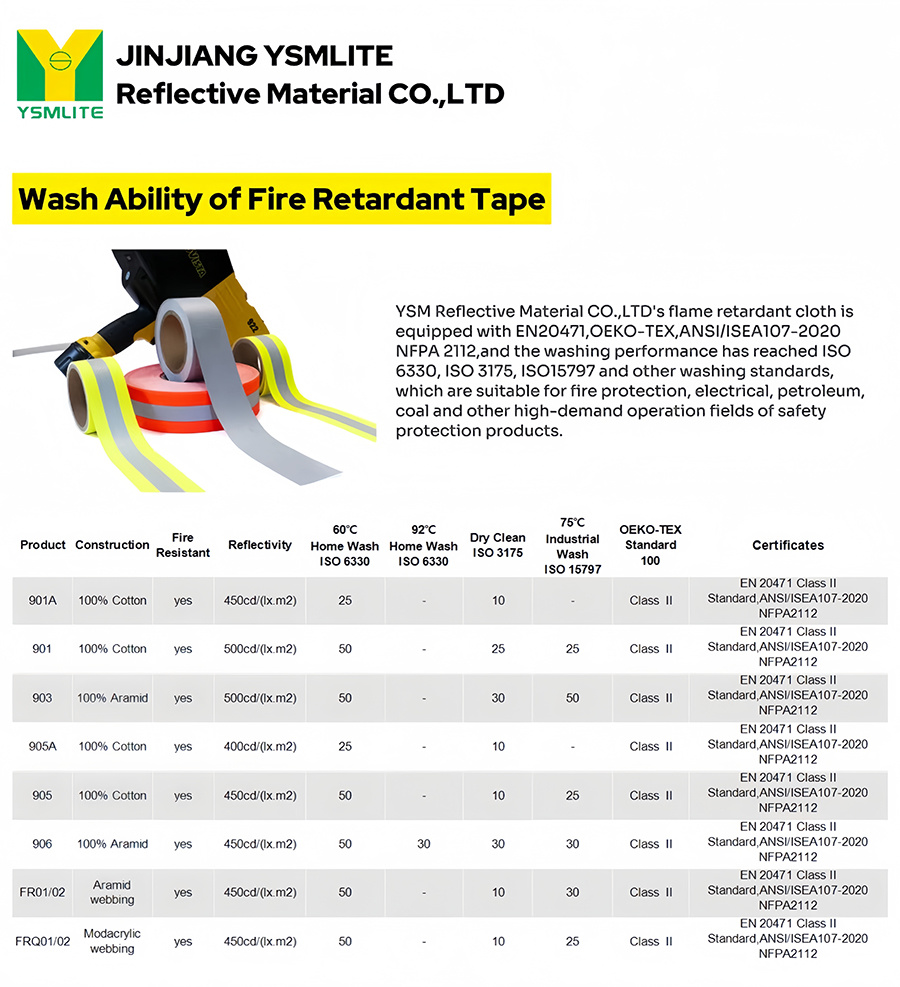

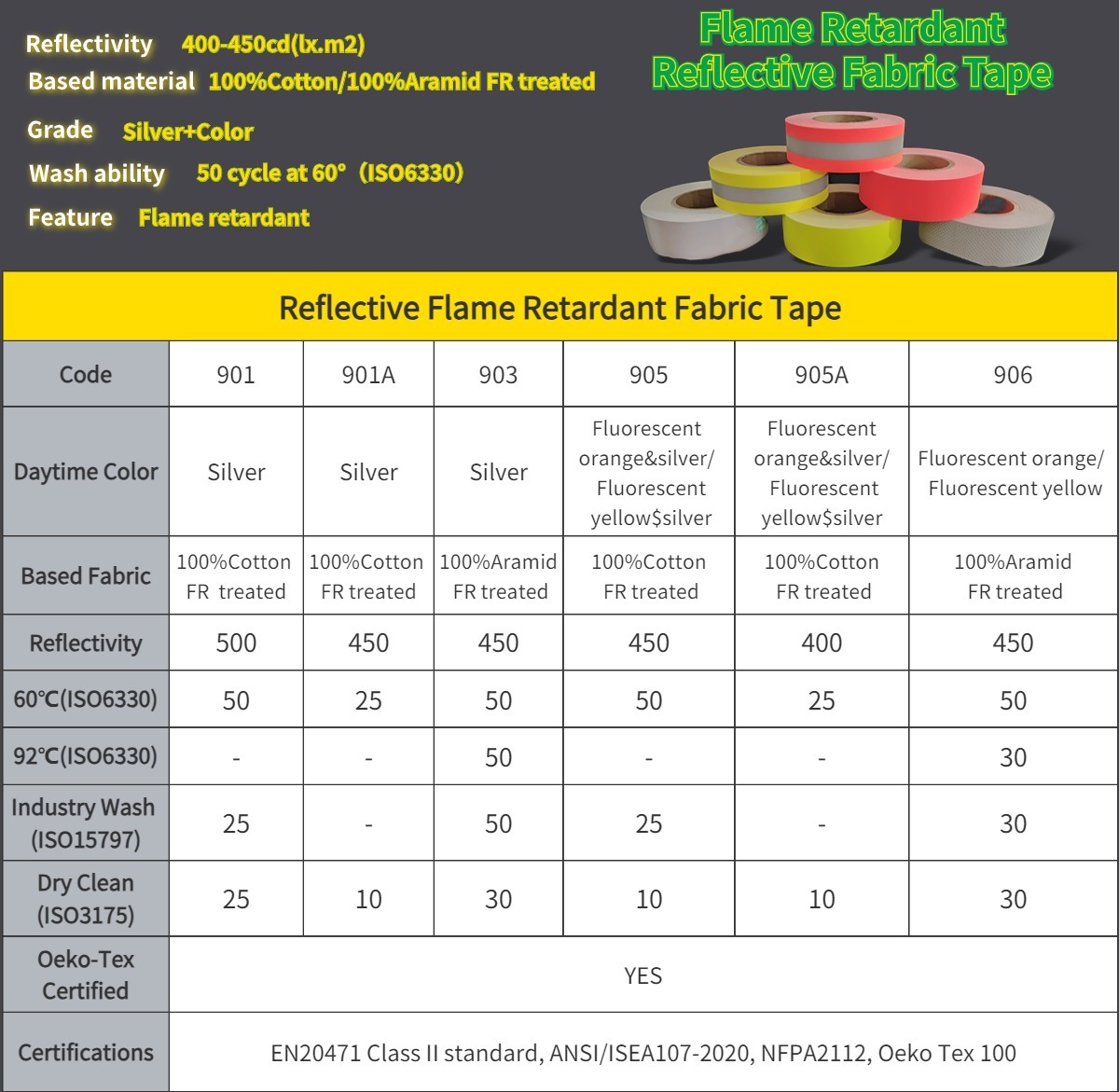

In the flame retardant reflective tape products of manufacturers such as YSM, models such as YSM-903 use 100% aramid FR treatment as the substrate, which can maintain a high reflectivity of 450 cd/lx/m² while maintaining excellent performance through 50 industrial washing tests, fully demonstrating the application value of aramid fiber in high-performance safety materials.

Which industries need aramid flame retardant reflective tape the most? Why?

Aramid flame retardant reflective tape is widely used in multiple high-risk industries due to its unique combination of properties. Here are a few key industries that need this high-performance safety material the most:

- Firefighting industry: Firefighters often need to work in smoke-filled fire environments with extremely low visibility. Aramid flame retardant reflective tape is used on firefighting clothing, which not only improves the visibility of firefighters in thick smoke, but also maintains structural integrity in high-temperature flame environments without burning or melting, providing additional safety guarantees.

- Mining industry: Mining environments are usually dimly lit and there are safety hazards such as coal dust explosions. Aramid flame retardant reflective tape on miners' work clothes can not only improve workers' visibility in dark environments, but also provide flame retardant protection in the event of fire or explosion.

- Smelting and steel industry: The working environment in these industries is often accompanied by dangers such as high temperature and molten metal splashing. Workers' protective clothing needs to have excellent high temperature resistance and flame retardancy, and also needs to have good visibility to prevent accidental collisions. Aramid flame retardant reflective tape meets these requirements.

- Power industry: High visibility is essential when electricians work at night or in low-light environments. At the same time, the high temperatures generated by arc flashes also require the protection of flame retardant materials. The electrical insulation and flame retardancy of aramid flame retardant reflective tape make it an ideal material for electrician work clothes.

- Oil and gas industry: The working environment of oil fields is complex, with both flammable substances and various mechanical equipment. Workers need to be clearly identified in any lighting conditions, and protective clothing needs to be able to resist possible fire risks. Aramid flame retardant reflective tape can meet these stringent requirements.

The reason why these high-risk industries need aramid flame retardant reflective tape is mainly because their working environment has both low visibility and high temperature/fire risks. Ordinary reflective materials are prone to deformation or burning in high temperature environments, and ordinary flame retardant materials cannot provide sufficient visibility. Only high-performance composite materials such as aramid flame retardant reflective tape can simultaneously meet the multiple safety needs in these harsh environments.

Professional manufacturers such as YSM clearly state that the application scenarios of their flame-retardant reflective tapes include fire safety clothing, coal mine work clothes, smelting work clothes, electrician work clothes, personal belongings and oil field work clothes, fully covering the needs of the above high-risk industries.

How to choose the best aramid flame retardant reflective tape for your needs?

Choosing the right aramid fireman reflective tape is critical to ensuring safety and performance. Here are a few key considerations to help you make an informed choice:

Substrate type: Choose the right substrate based on the actual working environment. 100% aramid substrate has the best high temperature resistance and flame retardant properties, suitable for extreme environments; while 100% cotton substrate with flame retardant treatment takes into account both comfort and flame retardancy, suitable for work scenarios that require long-term wear.

Reflectivity requirements: Different working environments have different requirements for reflective performance. For example, in extremely low-light environments such as mines or nighttime road operations, high-performance products with a reflectivity of 450-500 cd/lx/m² should be selected; while in environments with better light conditions, products with moderate reflectivity can be selected.

Color selection: Aramid flame retardant reflective tape is usually available in silver, fluorescent yellow, and fluorescent orange. Choose the right color according to the application scenario: silver has the best reflective effect at night; fluorescent yellow has the highest visibility during the day; fluorescent orange performs well in a variety of light conditions and is particularly suitable for occasions that require high visibility all day long.

Width and specifications: Choose the right width according to the application requirements. Generally speaking, the main reflective tape width of safety clothing is 5cm, which meets the requirements of most safety standards; while small items such as hats and gloves can choose narrower reflective tapes. YSM offers a variety of specifications with widths ranging from 1cm to 10cm.

Washing durability: If the working environment is prone to contamination of protective clothing and requires frequent washing, products with high washing durability should be selected. High-quality aramid flame-retardant reflective tapes can still maintain more than 90% reflective performance and complete flame-retardant properties after 30-50 industrial washings.

Certification and standards: Make sure the selected product meets relevant industry standards and certification requirements. For example, EN 20471 Class II is the European requirement for high-visibility clothing; ANSI/ISEA 107-2020 is the relevant standard in the United States; and NFPA2112 is the standard for flame-retardant workwear. It is usually more reliable to choose products that meet multiple certifications at the same time.

Application method: Consider how the tape is installed. Some aramid flame-retardant reflective tapes are designed to be sewn onto the substrate; while others may provide heat transfer or self-adhesive installation options. Choose the appropriate installation method based on actual application needs and available tools.

By looking at the product specification sheets provided by manufacturers such as YSM, you can compare the performance parameters of different models. For example, YSM-901 (100% cotton FR treatment) provides 500 cd/lx/m² reflectivity and 50 wash durability, while YSM-903 (100% aramid FR treatment) provides 450 cd/lx/m² reflectivity and more comprehensive durability (including 50 dry cleanings and 30 industrial washes). Choosing the most suitable model according to specific needs can ensure the best safety and user experience.

What is engineering grade aramid flame retardant reflective tape? How is it different from ordinary grade?

In the aramid fire resistant reflective tape market, products are usually divided into different performance grades, among which engineering grade is a common high-performance classification. Understanding the characteristics of engineering grade products and the differences from ordinary grade products is crucial to choosing the right safety material.

Engineering grade aramid flame retardant reflective tape refers to high-end products that meet or exceed the strict standards of engineering applications in terms of reflective performance, flame retardancy and durability. This type of product usually uses the most advanced micro-prismatic reflective technology, with a reflectivity of up to 500 cd/lx/m², which is much higher than the standard requirement of 350-450 cd/lx/m², ensuring excellent visibility even in extreme low light environments.

Compared with ordinary grade flame retardant reflective tape, engineering grade products have the following significant differences:

- Reflective performance: Engineering grade products have higher reflectivity, usually reaching 450-500 cd/lx/m², while ordinary grade products generally have a reflectivity between 350-400 cd/lx/m². This means that under the same light conditions, engineering grade products can provide better visibility and longer recognition distance.

- Durability: Engineering grade products excel in water washing durability, and can withstand more than 50 industrial water washings while maintaining more than 90% of reflective performance, while ordinary grade products can usually only guarantee stable performance for 10-25 water washings. From the product specification table of YSM, we can see that engineering grade products such as YSM-901 and YSM-903 provide 50 water washing durability, while ordinary grade products such as YSM-901A and YSM-905A only provide 25 or 10 water washing durability.

- High temperature resistance: Engineering-grade aramid flame-retardant reflective tapes usually use 100% aramid substrates, which can maintain structural stability at high temperatures, while ordinary-grade products may only use part of aramid or flame-retardant cotton cloth, and have relatively weak temperature resistance.

- Certification level: Engineering-grade products usually comply with multiple international authoritative certifications, such as EN 20471 Class II, ANSI/ISEA 107-2020, NFPA2112, and Oeko Tex 100, while ordinary-grade products may only meet basic safety standards.

- Application scenarios: Engineering-grade products are mainly used in high-risk environments, such as firefighting, mining, petrochemicals and other industries, while ordinary-grade products are more suitable for general industrial environments with relatively low risks.

When choosing, you should determine whether you need engineering-grade products based on the risk level and usage requirements of the actual working environment. For high-risk occupations such as firefighters, miners, and high-temperature smelting workers, engineering-grade aramid flame-retardant reflective tape is undoubtedly a safer choice; while for general industrial environments or temporary low-risk work, ordinary-grade products may be sufficient to meet basic safety needs.

As a professional flame-retardant reflective tape manufacturer, YSM provides a variety of product options, including engineering-grade YSM-901/903 series and standard-grade YSM-901A/905A series, which can meet the needs of different application scenarios.

How to properly install and maintain aramid flame retardant reflective tape to extend its service life?

Proper installation and maintenance are essential to fully utilize the performance of aramid flame retardant reflective tape and extend its service life. Here are some practical installation and maintenance suggestions:

Installation tips

Surface preparation:

- Make sure the installation surface is clean, dry and grease-free. Clean the surface with alcohol or special cleaner and make sure it is completely dry before installation.

Sewing installation:

- Use high-temperature resistant aramid thread for sewing, ordinary thread may not withstand high temperature environment.

- The stitching density is maintained at 5-7 stitches per inch to ensure firmness without damaging the material.

- Sewing 2-3mm away from the edge of the tape to avoid falling off due to being too close to the edge.

- Avoid overstretching the material when sewing to avoid affecting the reflective performance or causing deformation during use.

Location selection:

- Determine the installation location of the tape according to relevant safety standards (such as EN 20471), usually including the chest, waist, shoulders and legs.

- Avoid installing in areas with frequent bending or friction to reduce wear.

- Ensure that the tape is exposed to light from all angles to maximize visibility.

Maintenance methods

Washing instructions:

- Follow the product's washing instructions. Neutral detergents are generally recommended.

- The water temperature should not exceed 60°C to avoid affecting the reflective performance. YSM's product specification sheet clearly indicates that its products can withstand industrial water washing at 60°C.

- Avoid using bleach, strong alkaline detergents or chlorine-containing detergents, which may damage the reflective material and flame retardant properties.

- If possible, choose to wash the reverse side to reduce direct friction with the reflective surface.

Drying method:

- Prefer natural air drying or low temperature tumble drying (not exceeding 60°C).

- Avoid exposure to direct sunlight for long periods of drying. Ultraviolet rays may cause the reflective material to age.

- Do not iron directly in contact with the reflective surface. If necessary, iron the reverse side at low temperature or use a steam iron.

Regular inspection:

- Check the reflective material for damage, shedding or obvious dirt after each use.

- Use a flashlight to test the reflective effect in a dark environment to ensure that the reflective performance is still good.

- If the reflective effect is significantly reduced, you should consider replacing it, even if the appearance still looks intact.

Storage recommendations:

- Store in a dry, cool environment, away from direct sunlight and humid environments.

- Avoid contact with sharp objects to prevent scratches on the reflective surface.

- For long-term storage, it is recommended to lay flat rather than fold to avoid permanent creases.

Dirt treatment:

- Light dirt can be gently wiped with a damp cloth.

- Stubborn dirt can be gently brushed with a soft brush and neutral detergent, and then rinsed with clean water.

- Oil stains can be treated with professional safe cleaning solvents, but long-term contact should be avoided to avoid affecting the flame retardant performance.

By following these installation and maintenance recommendations, you can significantly extend the life of the aramid flame retardant reflective tape, ensuring that it provides reliable safety protection throughout its entire service life. Remember, even the highest quality safety materials require correct use and maintenance to perform at their best.

Conclusion

Aramid flame retardant reflective tape is an important innovation in the field of modern safety protection. It successfully combines high reflective performance with excellent flame retardant properties, providing double safety protection for workers in high-risk industries. By using aramid fiber as the substrate, this professional safety product can maintain structural stability in extreme environments while providing excellent visibility and effectively reducing work risks.

When choosing aramid flame retardant reflective tape, it is necessary to comprehensively consider the characteristics of the working environment, safety standard requirements and product performance parameters to select the product that best suits actual needs. Proper installation and maintenance are the key to ensure that these high-performance safety materials perform at their best and extend their service life.

Aramid flame retardant reflective tape products provided by professional manufacturers such as YSM have passed a number of international authoritative certifications, such as EN 20471 Class II standard, ANSI/ISEA 107-2020, NFPA2112 and Oeko Tex 100, ensuring the compliance and reliability of the products worldwide. These products not only have a reflectivity of up to 450-500 cd/lx/m², but also maintain more than 90% of reflective performance and complete flame retardant performance after multiple industrial washings, fully reflecting the advanced level of modern safety material technology.

With the continuous improvement of safety awareness and the continuous development of technology, the field of aramid flame retardant reflective tape is also constantly innovating, such as developing lighter and more comfortable materials, improving reflective efficiency, and enhancing environmental protection performance. These advances will further improve the safety level of the workplace and provide more comprehensive protection for workers in various industries.

Whether you are a safety equipment purchaser, engineer, or a worker who directly uses these safety products, understanding the characteristics and correct use of aramid flame retardant reflective tape will help maximize the safety of the operation and allow every worker to return home safely. After all, we can never compromise on safety issues.

Related News

What Does It Mean That FR Reflective Tape Has Passed NFPA2112 and NFPA1971 Certification?

2025-06-11

Top 5 FR Reflective Tape Manufacturers in Europe

2025-06-10

Common Problems and Solutions When Using Reflective Webbing Tape

2025-06-09