What Does It Mean That FR Reflective Tape Has Passed NFPA2112 and NFPA1971 Certification?

2025-06-11

Ysmlite

ysmlite.com

People working in high-risk environments, such as chemical plant operators, firefighters, power maintenance workers, and technicians on oil drilling platforms, may face deadly risks such as fire, explosion, or high temperature burns every day. In such work scenarios, clothing is not just a piece of clothing to cover the body and keep warm, but a "last line of defense". Among them, flame retardant reflective tape, which is widely used in safety clothing and protective clothing, plays a vital role - it must not be ignited in the flame, but must ensure that the wearer is still clearly visible in the dark and smoke.

However, the fire retardant reflective tapes on the market are of varying quality, and many products have only undergone basic fire protection treatment, but lack systematic testing. At this point, whether or not it has passed NFPA2112 and NFPA1971 certification becomes a "hard indicator" for judging the safety level of the material. It not only represents a compliance threshold, but also a manifestation of a safety commitment.

Ysmlite deeply analyzes NFPA2112 and NFPA1971, two globally recognized flame retardant standards, to reveal the test logic, application value, and certification threshold behind them, and explains what the certified flame retardant reflective tape can "do" and why it is worth choosing.

Detailed explanation of NFPA2112 standard

NFPA2112, the full name of which is "Standard for Protective Clothing for Industrial Personnel from Flame Flash Hazards", was formulated by the National Fire Protection Association (NFPA) of the United States and is mainly used in industrial scenarios such as petrochemicals, oil and gas, electricity, and steelmaking. The core purpose of this standard is to ensure that the protective materials worn by workers can maximize the escape time and reduce burns when facing explosive flame flashes through specific test items.

Core test items include:

- Vertical Flame Test: simulates whether clothing or tape can be quickly extinguished after contact with open flame. After the test, observe whether the material continues to burn, drip, and whether the carbonization length meets the standard (usually ≤100mm).

- Thermal Protective Performance (TPP): measures the ability of the material to block heat transfer. The higher the value, the longer it can delay the occurrence of second-degree burns on the skin. NFPA2112 requires ≥6 cal/cm².

- Heat shrinkage test: heat at a specific temperature (usually 260°C) for a certain period of time to detect whether the material has severe shrinkage and deformation.

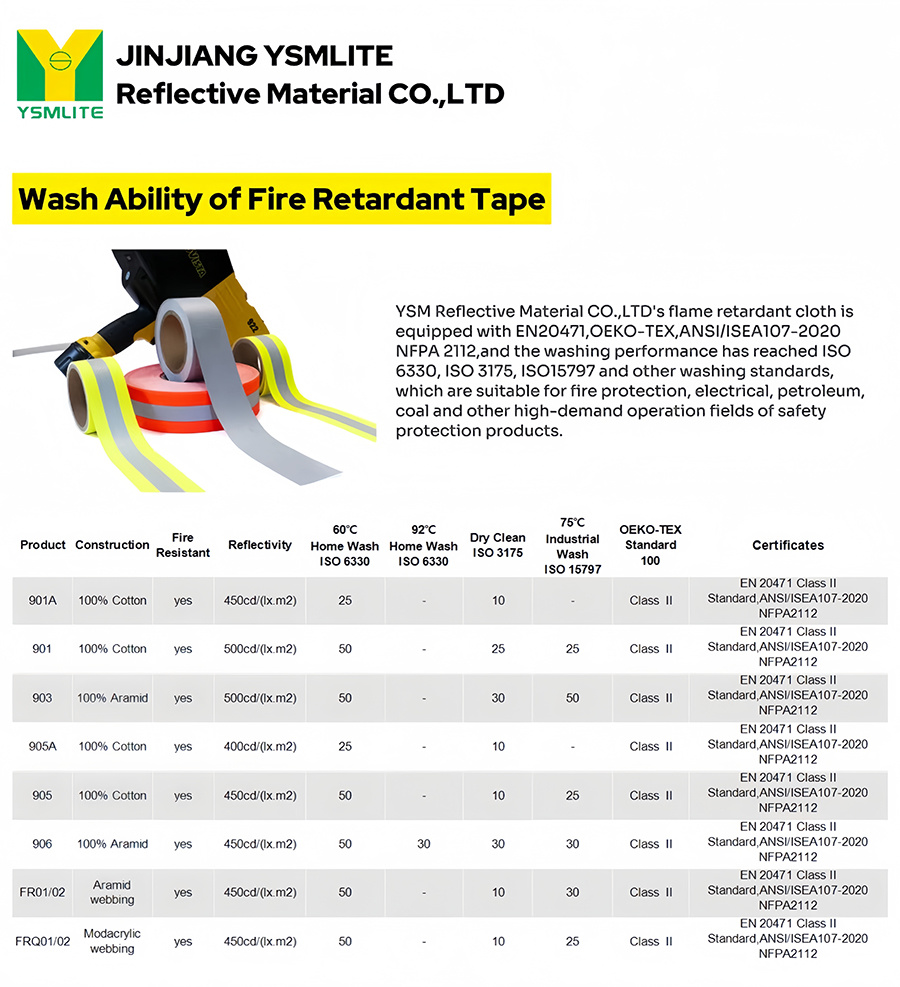

- Post-washing performance consistency test: the product must maintain its flame retardant ability after 25 industrial washes.

Practical significance:

- Products that pass the NFPA2112 standard mean that even in a high-temperature flame environment, the flame-retardant tape will not become a secondary ignition source, and at the same time, it can still ensure reflective visibility during the critical escape time to protect the operator to the maximum extent.

Unlike NFPA2112, which is aimed at industrial workers, NFPA1971 Standard for Structural Firefighter Protective Equipment is a standard tailored for firefighters. This standard has more stringent requirements for protective materials because firefighters need to work in more extreme environments, such as high temperature and dense smoke, oil and gas combustion, and violent explosions.

The key test items are as follows:

- Heat exposure test: Expose to a heat flux of 50kW/m² for 10 seconds to detect the surface temperature rise and performance stability of the material.

- Thermal radiation protection test (Radiant Heat Performance): Evaluate the heat absorption and conduction capacity of reflective tape in continuous thermal radiation.

- Washing and abrasion resistance test: The reflective brightness of the tape is required to be no less than 80% of the initial value after 25 washes (standard washing liquid + mechanical vibration), and the flame retardant performance does not decay.

- Reflective coefficient requirements: Under the certification requirements, the reflective coefficient in the dry state is ≥420 cd/lux/m², and it must still be ≥270 cd/lux/m² after wetting.

Practical significance:

- Tapes certified by NFPA1971 can not only be used in firefighting clothing, but are also widely used in ultra-high standard industries such as airport emergency rescue, tunnel operations, explosion-proof firefighting systems, and aerospace special clothing.

Two major NFPA certifications give flame-retardant reflective tapes key performance

FR reflective tapes that have passed NFPA2112 and 1971 dual certifications no longer remain at the "basic fire protection" level, but have a complete and reliable high-performance indicator system.

Core performance overview:

- Continuous flame retardant performance: extinguish immediately after the fire source is removed, no melting drips, no combustion.

- High temperature protection ability: the material can still maintain physical stability in an environment of 260~700°C.

- Strong reflective visibility: the reflective performance is still stable in low light, smoke, dust and other environments.

- Outstanding washability and wear resistance: suitable for industrial washing, rain and snow conditions, and long-term use in outdoor environments.

Strong mechanical adhesion: not easy to delaminate or peel off, suitable for hot pressing and sewing of various clothing fabrics.

The comprehensive manifestation of these properties enables the product to maintain its protective effect in the face of complex risk scenarios such as high temperature, humidity, and oil pollution, ensuring the safety of frontline personnel.

How does YSM flame retardant reflective tape pass and exceed NFPA certification requirements?

As a domestic professional reflective material manufacturer, YSM is based on the highest international certification standards at every step from design, research and development to testing.

Material selection:

- Imported aramid base fabric or flame-retardant polyester composite fabric is used to balance strength and flame retardancy

- The surface is coated with high-density micro-glass beads and matched with flame-retardant polyurethane adhesive to achieve the unity of reflective brightness and fire resistance

Manufacturing process:

- Multiple hot pressing and laminating technology ensures that the tape does not delaminate under high temperature and high humidity conditions

- The reflective layer can be washed ≥40 times (far exceeding the certification standard of 25 times)

Test certification:

- NFPA2112/1971 dual certification authorized by SEI

- The laboratory is equipped with vertical combustion instrument, thermal radiation box, reflective tester, industrial washing machine and other equipment for factory inspection

Customer application and market performance:

- Successfully supplied North American protective clothing brands, European industrial uniform suppliers, and Southeast Asian fire equipment integrators

- Provide ODM services, support customers to customize patterns/shapes/colors/reflective levels, and ensure that each batch of materials is traceable

What does NFPA certification mean to global buyers

In the global market, flame-retardant reflective materials are no longer an "option", but a mandatory standard for key industries. From a purchasing perspective, NFPA certification brings not only a "compliance certificate", but also a bonus of brand trust and business opportunities.

Compliance:

- Complies with the requirements for PPE flame retardant products in regulations such as the US OSHA, European CE, and Canadian CSA

- Products certified by NFPA can be given priority in customs import audits, government bidding, and labor protection product bidding

Safety guarantee:

- Purchasing NFPA-certified tape means providing users with real and reliable life protection

- In the event of a safety accident, it can be used as an important basis for exemption and insurance claims

Brand and market impact:

- Overseas customers trust certified suppliers more, which is conducive to stabilizing long-term cooperative relationships

- More qualified and persuasive when expanding high-end markets (such as military industry, emergency management, and national energy systems)

Flame retardant reflective tape may seem like a tiny accessory, but it plays a "life-or-death" role in high-risk operations. Passing the certification of NFPA2112 and NFPA1971 is not only a proof of product performance, but also a solemn commitment to the life safety of users.

YSM always believes that "every centimeter of tape is a protection for life". In the future, YSM will continue to cultivate high-performance flame-retardant reflective materials to help more industry customers build a solid safety line of defense.

Whether you are a protective clothing manufacturer, an overseas trader, or an end user, choosing authoritatively certified YSM products is not only responsible for safety, but also for the future.

Related News

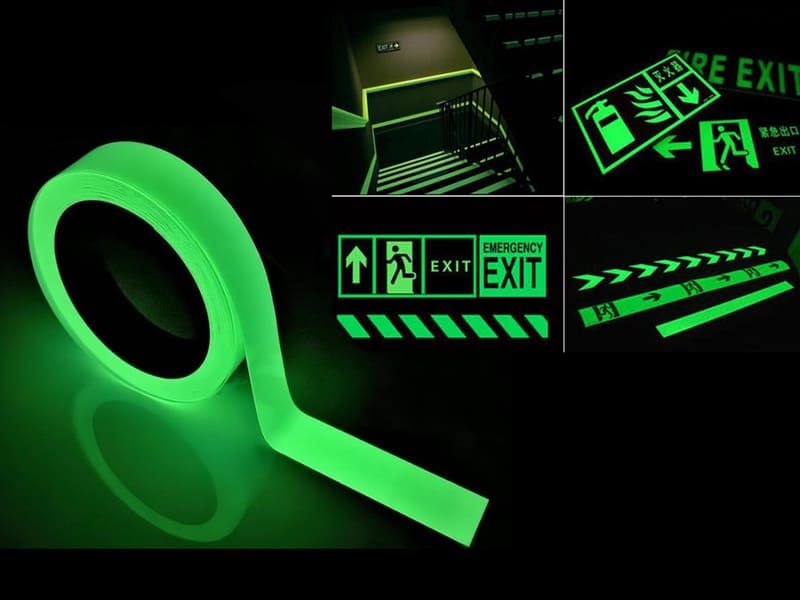

Applications of Glow in the Dark Film in Emergency Signage

2025-07-25

Application of Flame Retardant Reflective Tape in Coal Mining Workwear

2025-07-24

Application of Luminous Film on Clothing

2025-07-22