Top 5 FR Reflective Tape Manufacturers in Europe

2025-06-10

Ysmlite

ysmlite.com

Whether it is an engineering vehicle driving at night or a firefighting uniform for emergency situations, as long as there is "invisible is dangerous", flame retardant reflective tape is the silent guardian behind those heroes. You may never notice it, but whenever the traffic lights are dim and the smoke is thick, it is these tapes that allow you to see, remember and avoid at critical moments. In Europe, this type of material is not only a battlefield for safety sales and regulatory challenges, but is also driving the entire industry towards "brighter, safer and more environmentally friendly".

Ysmlite will take you to an in-depth understanding of the five most influential fire retardant reflective tape manufacturers in Europe: Orafol of Germany, 3M Europe of Belgium, Reflexite Europe of the Czech Republic, Coats Signal of the UK, and of course the rapidly rising YSM. We will not only talk about their actual cases in the European market, but also talk about your essential guide to choosing tapes, the operating tips you must know for installation and maintenance, and finally look forward to the future prospects of this industry together. Whether you are a purchasing manager, an engineer, or a passionate enthusiast of safety equipment, you can find "dry goods" here that are stable, useful and visible.

Next, let's open this "reflective and flame-retardant" European door together!

Why flame-retardant reflective tape is so important in the European market

Driven by EU regulations: from safety standards to commercial compliance

In Europe, the pulse of the entire industry is not simply "the cheaper the better". Over the years, the EU has gradually implemented strict safety regulations, and has specific flame retardant (such as EN ISO 14116) and reflective properties (such as EN 17353) for clothing, vehicles, public facilities, etc. Once these tapes are applied, but the test fails to meet the standards, it means that the product cannot be put on the market, and even more seriously, it may face recalls. For multinational buyers and engineering units, this is a typical trap of "buying but not using".

Hard needs in multiple industry scenarios: firefighting, transportation, industry

Think of a highway at night, or a fire in thick smoke: firefighters rushing over in reflective uniforms, rescuers directing in tunnels, and construction workers standing by bridges waving. Each scenario is highly relevant to the combination of "reflective tape + flame retardant", especially light reflection can be life-threatening and burning can destroy equipment. These scenarios in Europe are stressful and have high safety requirements, and there are rigid requirements for tapes to resist smoke, high temperature, and long-term high-intensity use.

Market trend: Demand continues, innovation brings dividends

In the past five years, the average annual growth rate of the European flame retardant reflective market has been close to 6%. With the expansion of the urban night economy and the enhancement of energy-saving and environmental awareness, the market demand for high-brightness and high-environmental adaptability materials is increasing. Especially in an era of upgraded regulations and increasingly scattered urban lights, tapes that take into account both brightness and durability have become "hot cakes".

Introduction to the top 5 flame-retardant reflective tape manufacturers in Europe

Criteria for selection

To measure a top FR reflective tape manufacturer, we focus on the following comprehensive criteria:

- Technical strength: product brightness (cd/lx·m²), flame retardancy level (M level, EN rating)

- Product certification: whether it has obtained authoritative certifications such as CE, DIN, NFPA

- Breadth of application: whether it can cover multiple fields such as fire protection, transportation, clothing, industry, etc.

- Market feedback: real customer cases and long-term reliable performance

- Innovation and environmental protection: whether halogen-free flame retardants or recyclable materials are used

The following five manufacturers have performed well in these dimensions, forming differentiated competition and synergy.

Orafol (Germany)

As a representative of German industrial design, Orafol has accumulated more than 30 years of technology in the field of reflective materials. Its reflective tapes are widely used in highway signs, railway area warnings, fire clothing reflective strips, etc., with a brightness of up to 600-1200 cd/lx·m², which can be clearly distinguished from 2 meters away. The micro-prismatic structure it uses can accurately reflect the light from car lights and increase the viewing distance by up to 2 times.

3M Europe (Belgium)

3M is the "big brother" in the field of reflective materials, and has additional strengths in the field of flame-retardant reflective tapes. Its "engineering-grade" products meet the NFPA 701 flame-retardant certification, and use a patented adhesive structure, which has anti-peeling and moisture-proof properties. Many European firefighting clothing and rescue signs use this solution, which is visible and reassuring.

Reflexite Europe (Czech Republic)

Reflexite focuses on micro-prismatic technology. Its flame-retardant reflective tape uses PET base + polyester material, with a medium temperature tolerance of up to 180°C, and can even withstand 250°C for a short time. It can be widely used in the fields of railways and welding clothing, taking into account brightness and thermal stability, and is a good partner for working in hazardous environments.

Coats Signal (UK)

Coats Signal originated from the background of the traditional textile industry and is good at combining flame-retardant reflective with fabric applications. Its thermally cut reflective tapes can pass the flame retardant standard in one stop after the garments are sewn together, without the need for secondary film application, which greatly reduces the construction difficulty and equipment cost.

YSM (Chinese brand goes to Europe)

Although it originated in China, YSM has quickly obtained project certification in Europe and has become an important supplier of flame retardant materials for safety clothing and consumer clothing. Its flame retardant reflective tapes have a reflective brightness of more than 500 cd/lx·m², which meets the dual standards of EN ISO 20471 and EN ISO 14116.

Analysis of product advantages and core technologies of the five major manufacturers

Orafol: High brightness and wide viewing angle

With a unique arrangement of micro-prismatic reflective elements, Orafol's reflective tape can capture incoming light in a range of nearly 180°. Whether on the driver's side, blind spot or side mirror, the high-brightness light source effect can be sensed 100 meters away. German TÜV tests show that the fit is good at room temperature and -20°C, suitable for use in extreme cold or heat.

3M Europe: Material and safety

3M proposed the concept of "double flame retardant": both the backing layer and the surface core layer contain flame retardant ingredients, and the flame retardant mechanism is dispersed throughout the material. In actual tests, it was directly burned for 2 seconds in front of a 560°C high-temperature furnace, and there was no peeling or flame spread. The accompanying application guide is on the accompanying paper, which can shorten the construction screening time by 30%.

Reflexite Europe: High temperature resistance and stable structure

Using a multi-layer PET + adhesive film structure, the flame retardant performance takes into account light transmittance and will never melt or delaminate due to high temperature. Czech technical laboratory experiments have confirmed that 90% of the original peel strength is maintained after 3,000 high-temperature-low-temperature cycles. Suitable for high-temperature environments such as outdoor welding areas and tunnel excavation.

Coats Signal: Convenient application and clothing welding design

Coats is formed in one step through a thermal cutting process, so that the tape is flame-retardant after being attached to the T/C fabric, avoiding the risk of delamination of the film structure caused by secondary processing. When applied to clothing equipment such as fire masks and emergency straps, the durability of the pressing line is 40% higher than that of ordinary webbing.

YSM: Customization + dual certification is more flexible

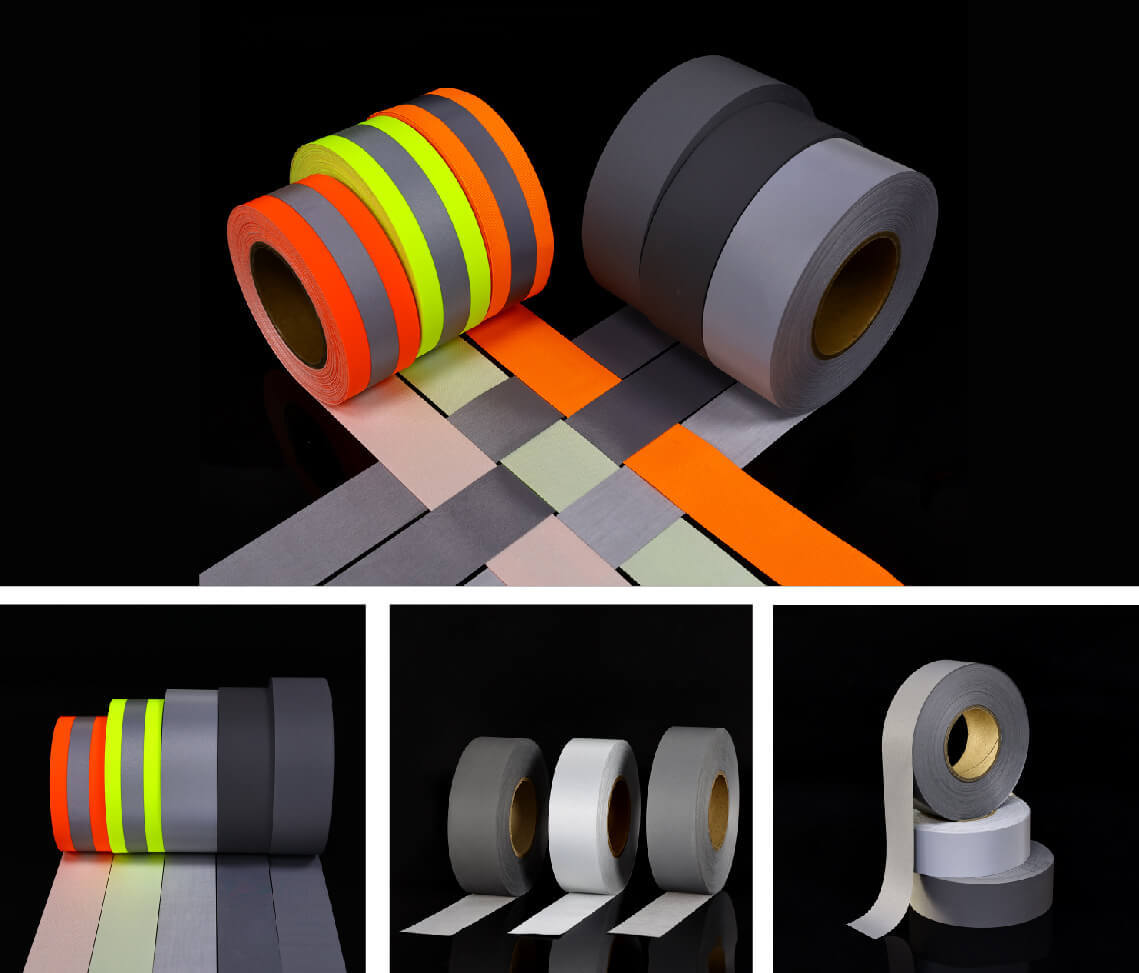

The flame-retardant reflective tape series launched by YSM in Europe has high brightness, and the flame-retardant level meets EN ISO 14116 Index 3, NFPA2112, and UL. More importantly, YSM can customize multi-color optional textured anti-counterfeiting elements such as burnt yellow and luminous green according to customer needs, and cooperate with OEM labels to enhance the professional image of the brand.

How to choose high-quality flame-retardant reflective tape

Practical and highly operational suggestions to help you use reliable materials:

Step 1: Clarify the use scenarios

High brightness requirements at night: such as road construction and emergency rescue, it is recommended to choose microprismatic products with a reflective brightness of ≥ 500 cd/lx·m².

Operation in high-temperature environments: such as welding, tunnels, and glass factories, PET structural tapes with a temperature resistance of more than 180°C are preferred.

Applications in clothing: fire suits and rescue vests should use flame-retardant tapes that can be hot-pressed with fabrics.

Step 2: Check the certificate and report

Flame retardant certification: EN ISO 14116 Index, NFPA 2112, NFPA1971.

Reflective brightness report: in accordance with EN ISO 20471, ANSI/ISEA 107.

Be sure to ask for the actual measurement report from the original manufacturer or third-party laboratory to check the completeness of the report (such as the test environment and light source type).

Step 3: Confirm the construction and lamination method

Is it suitable for hot pressing, stitching, or cold lamination?

Are lamination training and lamination tools provided?

These details determine whether the on-site installation is convenient and the effect is long-lasting.

Step 4: Pay attention to durability and maintenance suggestions

Is there a cleaning guide? What cleaning method is suitable?

How many years can each tape maintain racing-level reflectivity?

A manufacturer willing to provide "future maintenance consultation" is often more worthy of long-term cooperation.

Step 5: Compare costs and services

The surface price is not the only consideration, and the transportation, installation, and rework costs should also be calculated;

After-sales response time and technical support accessibility determine the reliability of the brand.

Recommendations and maintenance tips for flame-retardant reflective tape

Key points for installation and construction

Always apply the tape on a clean, oil-free substrate, and use a rubber scraper to remove bubbles from it. Whether it is hot pressing or cold lamination, there are clear lamination temperature and time markings, which must be followed. When testing the strength, please perform the tensile test 24 hours after the attachment to avoid initial weak adhesion.

Tips for extending the service life

Store at 20–25°C and 40–60% humidity, avoid direct sunlight.

Use warm water + neutral detergent for cleaning, up to 30°C; resolutely avoid cleaning agents containing benzene to avoid damaging the reflective film.

Perform a self-inspection of the reflective brightness every six months. If it drops by more than 15%, it is recommended to replace it.

Industry application details

Clothing: Avoid the positive cutting line of clothing to prevent cracking at the fold.

Tents: Attach to the seams as a flame-retardant reflective strip; pay attention to the temperature difference between inside and outside, and it is recommended to reinforce the outer covering layer.

Traffic facilities: Pay attention to the integrity of the edges during installation, and do not leave any warping, otherwise rainwater will easily cause mildew and non-reflection.

The European market is rapidly transforming towards the integration of "high performance + environmental responsibility". New halogen-free flame retardants, recyclable PET substrates, and flexible structures that can fit obstacles (such as fabric clothing) are on the rise. At the same time, reflective material manufacturers such as YSM that have obtained industry certificates are becoming more and more popular in the market in regional procurement.

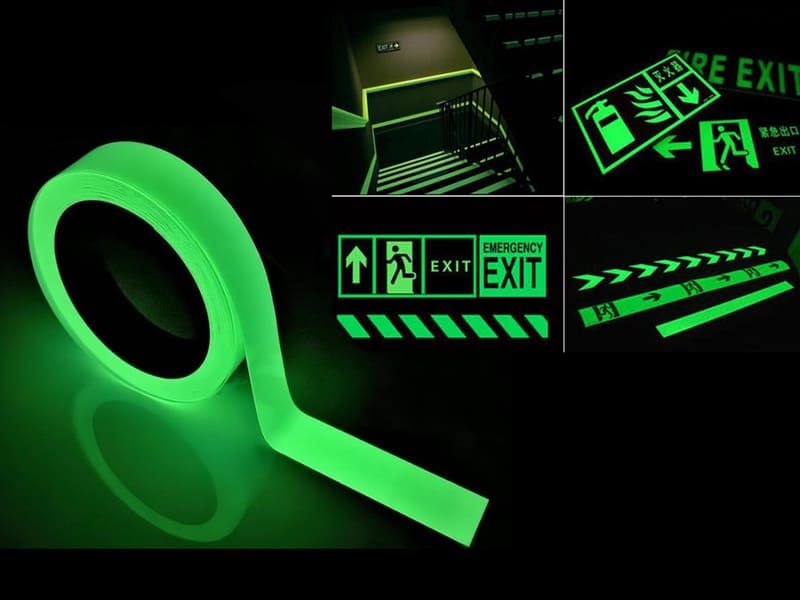

From the perspective of industry trends, customization will become a trend: for example, customizing colors for specific brands, adding traceable anti-counterfeiting textures, and dynamically meeting customers' dual personalized needs of "personal brand personality + safety standards". Looking at the technical level, the next wave of breakthroughs may appear in "visible + infrared reflective" or "reflective + light storage" composite tapes.

Related News

Applications of Glow in the Dark Film in Emergency Signage

2025-07-25

Application of Flame Retardant Reflective Tape in Coal Mining Workwear

2025-07-24

Application of Luminous Film on Clothing

2025-07-22