Common Problems and Solutions When Using Reflective Webbing Tape

2025-06-09

Ysmlite

ysmlite.com

Why is reflective webbing tape important? Is it really easy to use?

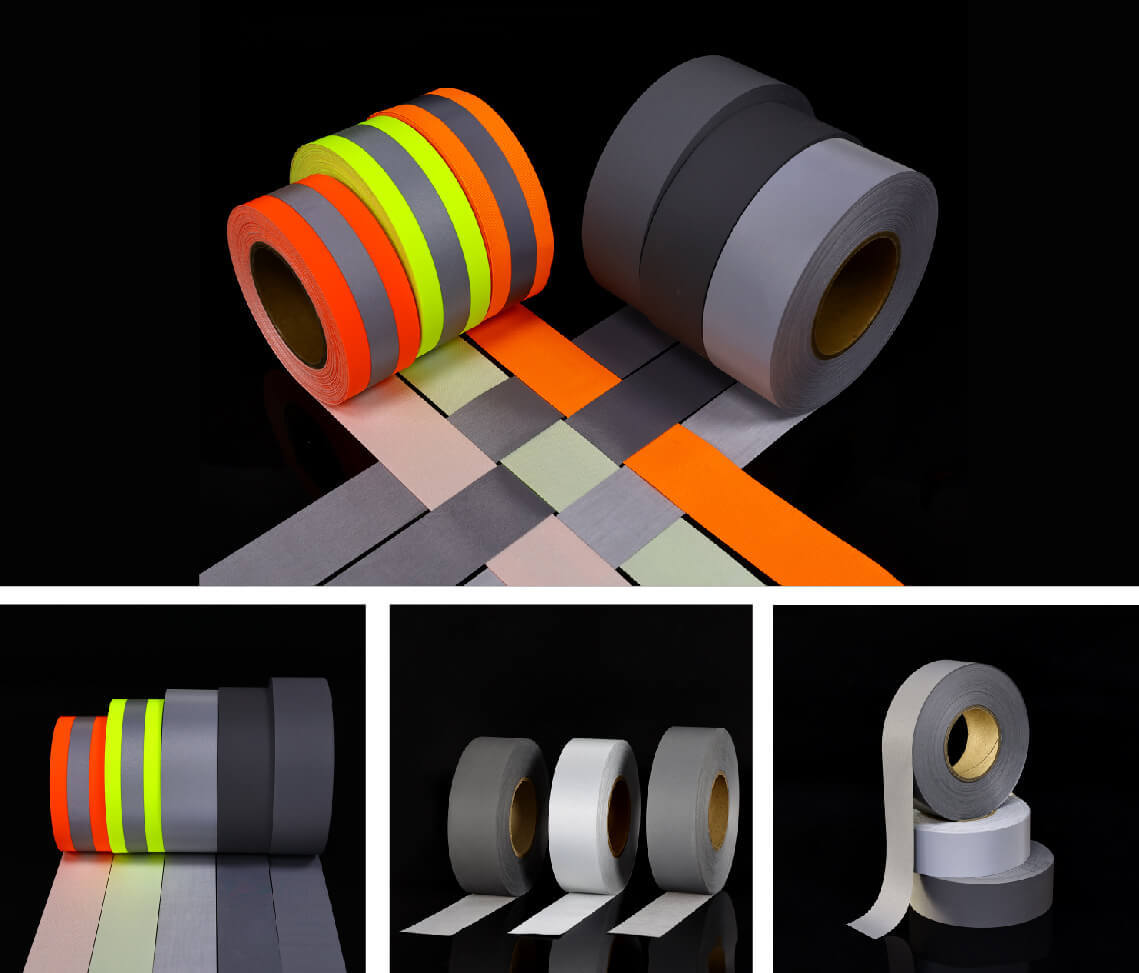

In modern industrial manufacturing, outdoor clothing design, safety equipment and traffic management, reflective webbing tape is used almost everywhere. It not only improves the wearer's visibility in dark environments, but also saves countless lives at critical moments. However, the seemingly simple reflective webbing tape actually contains quite complex technical principles and usage specifications.

The working principle of reflective webbing tape is based on "retroreflection" technology, which reflects external light sources (such as car lights and flashlight beams) back to the original path, making the wearer particularly eye-catching in low-light environments. For this reason, it is widely used in vests for construction workers, sportswear for night runners, children's school uniforms, pet supplies, and even professional equipment such as police and firefighting.

However, many users also face a lot of troubles during use: some reflective effects are not long-lasting, some tapes fall off frequently, and some clothes are no longer reflective after washing a few times. The root cause of the problem is not only the difference in the material itself, but also improper use methods, or even wrong selection. Therefore, understanding these common problems and mastering scientific countermeasures are important links that every user or purchaser cannot ignore.

Common problem 1: The reflective effect is not lasting or significantly weakened

Many users reported that the brightness of the reflective tape decreased significantly after using it for a period of time. In fact, there are many reasons that affect the reflective performance. First, the quality of the raw materials is unstable. Cheap products on the market often use inferior glass beads or matte coatings, resulting in inherent lack of reflective ability. Secondly, environmental factors should not be underestimated. The coating of reflective materials exposed to sunlight for a long time is easily decomposed by ultraviolet rays and falls off, resulting in weakened reflective ability.

In addition, incorrect cleaning methods can also cause the reflective layer to fall off. For example, using a hard brush to scrub vigorously, or high temperature and high speed treatment in an industrial washing machine will accelerate wear.

The fundamental solution to this problem lies in choosing high-quality products from the source. It is recommended to purchase reflective tape products that have passed the EN ISO 20471 standard test, and at the same time pay attention to whether the product's retroreflective coefficient is stable above 400 cd/lx/m². In addition, excessive sun exposure, friction and improper washing should be avoided in daily use to extend its reflective life.

Common Problem 2: Tape falling off or not firmly attached

Tape not firmly attached is one of the most troublesome problems in the actual application of reflective tape. Many times, soon after the user sticks on the tape, it starts to curl or even fall off. What's the problem?

First of all, consider whether the type of glue is suitable. Although pressure-sensitive adhesive is easy to use, it is sensitive to surface cleanliness and temperature; while hot melt adhesive has stronger adhesion, but installation requires hot pressing tools. Secondly, the material of the bonding surface also affects the bonding effect. If the surface is wet, oily, fuzzy or too smooth, the glue cannot adhere firmly.

Practical solutions include:

- Use a non-residue cleaner to clean the surface before pasting and let it dry naturally;

- For low surface energy materials (such as TPU, nylon), it is recommended to use a primer or surface treatment agent to enhance adhesion;

- Use a pressure wheel for secondary pressure to help the glue fully penetrate the fiber texture;

- For important parts, such as work clothes shoulders and elbows, stitched reflective webbing can be used instead of pure adhesive type.

YSM recommends that users use a hot press when using tape-type products, and apply pressure at 80~110℃ for 15 seconds, which can greatly improve the durability of the paste.

Common problem 3: Decreased reflective function after washing

Reflective webbing is often used on clothing, backpacks and other items that need to be washed repeatedly. It is a common problem that the reflectivity decreases significantly after washing several times. Tracing back the reasons, most of them are related to the washing method.

First of all, strong alkaline detergents, high-temperature water washing, drum dryers, and even organic solvents used in the dry cleaning process will destroy the structure of the reflective coating, causing the glass beads to fall off, thereby losing the reflective function.

Solving this kind of problem needs to start from the source:

- Choose reflective webbing that meets the ISO 6330 standard, which verifies that the product can withstand multiple home washings;

- Avoid using hot water above 60°C for washing. It is recommended to use warm water at 30°C~40°C and neutral detergent;

- Do not dry clean, because dry cleaning agents can easily damage the reflective coating structure;

- Dry naturally after washing, avoid dryers or sunlight exposure.

YSM has conducted internal washing comparison tests on its factory products: 50 consecutive washes at 30°C water temperature and gentle mode, the reflectivity remains above 90%.

Common problem 4: Poor surface adaptation of different materials

With the increasing popularity of diversified materials, reflective tapes are often used on different substrates such as EVA, TPU, nylon, polyester, PVC, etc., but many users report that they cannot be firmly attached. This is because the surface energy of these materials varies greatly, and it is difficult for glue to penetrate and produce sufficient adhesion.

Take nylon and TPU as examples. Although these two materials are widely used in clothing and luggage, their surfaces are extremely smooth and highly hydrophobic, and the glue adhesion effect is poor. In this case, the following countermeasures should be taken:

- Pre-treat the surface: such as using fine sandpaper to lightly polish or plasma treatment to increase the surface roughness;

- Apply surface accelerator: For example, 3M's Primer 94 can significantly enhance the glue adhesion;

- Use sewing or hot pressing instead of pasting;

- Select industrial hot melt adhesive designed for low surface energy materials.

In response to this problem, YSM has developed a specially formulated hot-pressed reflective webbing, which has been successfully applied to EVA materials in the outdoor equipment industry and has received good user feedback.

Common problem 5: Unstable performance in low or high temperature environments

Extreme temperature is another major culprit that affects the performance of reflective tape. Especially in cold areas or in summer exposure, the tape is prone to warping, hardening, brittleness or complete loss of stickiness. This is related to the thermal stability of the colloid formula.

In response to this problem, YSM recommends:

- Low-temperature application scenarios (such as outdoor work below -20℃): Use cold-resistant acrylic adhesive or polyurethane-based glue;

- High-temperature environment (such as summer workshop work or tropical areas): It is recommended to use industrial-grade hot-melt reflective tape, which has a higher softening point and bonding strength;

- Avoid placing the product in an environment with a temperature exceeding 45℃ and a humidity exceeding 80% for a long time during storage;

- Use heat-insulating and moisture-proof packaging boxes during transportation.

If temperature control verification is required, refer to ASTM D751 and ISO 188 thermal aging standards to conduct hot and cold cycle tests to verify the weather resistance of the product.

How to use and maintain reflective webbing tape correctly

To achieve the best performance of reflective webbing tape, correct use and daily maintenance are indispensable.

Preparation before pasting:

- Clean the surface to avoid dust, grease and moisture;

- Wipe the surface with alcohol and let it stand for 2 minutes;

- If the weather is cold, use a heat gun or hair dryer to slightly heat the surface.

Pasting process:

- Peel off the release paper and gradually apply the tape to the surface of the base;

- Use the pressure wheel to roll evenly along the pasting direction to prevent bubbles;

- The hot melt adhesive type needs to be pressed with a heat press for 10 to 20 seconds at a set temperature.

Post-pasting maintenance:

- Let it stand for 24 hours before use to ensure that the glue is completely cured;

- If used for clothing, it is recommended to wait 48 hours before the first wash;

- Avoid using an iron to directly iron the reflective part to prevent melting or discoloration.

Maintenance tips:

- Use a soft brush to brush gently to avoid scratching with hard objects;

- Store in a dry and ventilated environment to avoid high temperature exposure or humidity.

Although the reflective webbing tape is small, it carries the important responsibility of safety and visibility. By understanding its working principle, common problems and solutions, it can not only extend its service life, but also ensure its reliable performance at critical moments.

As a professional reflective material manufacturer, YSM has always been committed to the research and development and production of high-performance reflective webbing and tape. We provide professional customization services and technical support to users in different industries, helping customers choose the most suitable product type and optimize the use plan.

Don't let the wrong operation method drag down the excellent product performance. Let us work together to maximize the potential of every inch of reflective webbing.

Related News

Application of Flame Retardant Reflective Tape in Coal Mining Workwear

2025-07-24

Application of Luminous Film on Clothing

2025-07-22

Application of Flame Retardant Reflective Tape in Firefighter Equipment

2025-07-18