How to Make Photoluminescent Masterbatch? Comprehensive Analysis

2025-04-10

Ysmlite

ysmlite.com

Understand the importance of luminous masterbatch

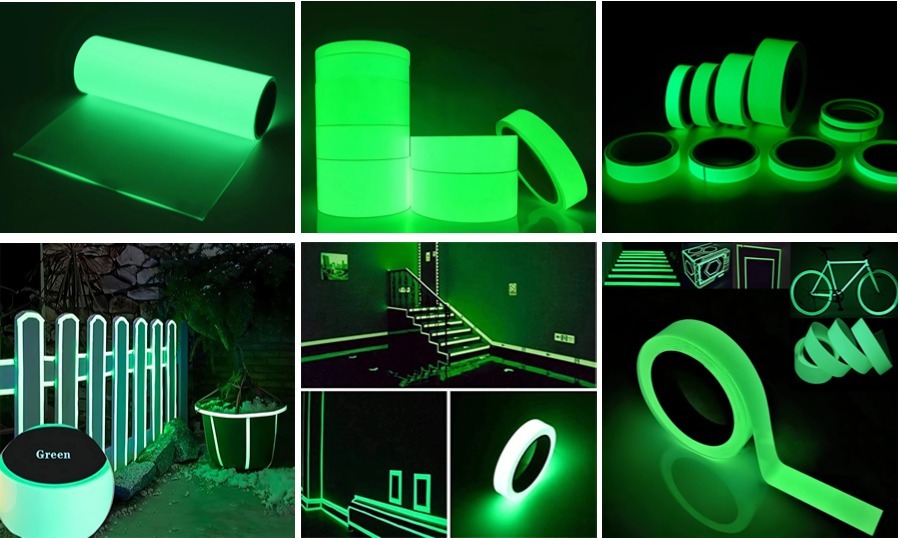

As an important raw material for luminous film, photoluminescent masterbatch is widely used in decoration, identification and safety instructions. With the continuous growth of market demand, the manufacturing process of luminous masterbatch is also constantly improving.

Before understanding this process, we must first understand the background, market value and development prospects of luminous masterbatch. The manufacture of luminous masterbatch is not a simple mixing of raw materials, but involves complex chemical reactions, physical changes and strict process control.

Principle and key materials of luminous masterbatch: What is luminous masterbatch?

Luminous masterbatch is a polymer masterbatch containing luminous pigments, which achieves significant brightness at night through the principle of light-induced luminescence. Simply put, it absorbs light energy during the day and releases the stored energy at night to emit light.

Basic principle:

- Luminous masterbatch mainly uses the principle of phosphorescence. Phosphorescent materials absorb energy under white light and slowly release energy in the dark, emitting a soft light.

- Commonly used materials include strontium aluminate and rare earth elements, which are precisely proportioned in the chemical process to ensure a continuous and stable luminous effect.

Key materials:

- High-performance polymers: mainly used as a matrix to ensure uniform dispersion of luminous pigments.

- Luminous pigments: such as strontium aluminate, silicate, etc., which can release light energy after absorption.

- Additives: used to improve mixing effect and stability, and ensure that the optical properties of raw materials are not destroyed during processing.

In short, understanding the principles and constituent materials of luminous masterbatch is the basis of the entire manufacturing process. Only by fully mastering the key materials and chemical reaction principles can the excellent performance of the final product be ensured.

Preparation before making luminous masterbatch: How to prepare production tools and raw materials?

Before starting to make luminous masterbatch, fully preparing the required production tools and raw materials is the key to success. Proper preparation not only ensures a smooth production process, but also improves product quality. Here are a few key steps:

Material preparation:

- Polymer matrix: Choose suitable thermoplastics, such as polypropylene (PP) or polyethylene (PE), which have good processing performance and weather resistance.

- Luminous pigment: Determine which type of luminous pigment to use and ensure that the products provided by the supplier have stable luminous performance. According to experience, beginners can choose mature and certified luminous pigments on the market.

- Auxiliary agents: Select auxiliary ingredients such as plasticizers and antioxidants to ensure uniform mixing and processing stability.

Equipment and tools:

- Mixing equipment: For example, a twin-screw extruder can ensure uniform mixing of materials.

- Temperature control system: Temperature control is crucial during the production process. It is recommended to use high-precision temperature control instruments.

- Detection instruments: such as spectrometers and microscopes, which are used to detect luminous performance and pigment dispersion.

Environmental requirements:

- Clean workshop: avoid dust and other impurities affecting the quality of luminous masterbatch.

- Temperature and humidity control: ensure that the production environment meets the material requirements, usually controlled within a certain range.

Detailed explanation of the production steps of luminous masterbatch: How to make luminous masterbatch?

This article will introduce the specific production steps of luminous masterbatch in detail. The whole process is divided into pre-treatment, mixing, extrusion and post-treatment, and each step requires precise control of process parameters.

Step 1: Raw material pretreatment

- Clean materials: ensure that the polymer matrix and luminous pigment are dry and free of impurities, and can be processed in a vacuum oven.

- Accurate weighing: accurately weigh each component according to the formula requirements to avoid insufficient luminescence or processing difficulties due to proportion problems.

Step 2: Material mixing

- Even mixing: put all the raw materials into the mixer, pay attention to adjusting the stirring speed and time, and ensure that the luminous pigment is fully dispersed in the polymer matrix.

- Observation status: detect the mixing status through the transparent observation window to ensure that there is no precipitation of large particles.

- Temperature control: Adjust the temperature of the equipment to ensure that the structure of the luminous pigment is not damaged by overheating. It is recommended to control the temperature between 180~220℃.

Step 3: Extrusion molding

- Equipment debugging: Set the parameters of the twin-screw extruder to ensure that the materials can still be evenly mixed under high shear force.

- Drawing cooling: The heated mixture needs to be drawn and quickly cooled to form a solid masterbatch.

- Extrusion monitoring: Real-time detection of product status, timely adjustment of process parameters, and stable discharge.

Step 4: Post-processing and packaging

- Shearing and granulation: Cut the long strip masterbatch into specified sizes for easy transportation and subsequent processing.

- Quality inspection: Use optical equipment to detect the luminous brightness and uniformity of the finished product, and record data for quality traceability.

- Storage: Store in a low humidity environment before packaging to avoid pigment aging or moisture absorption.

Notes:

- The temperature, speed and time of each step must be adjusted strictly according to laboratory data and production practice.

- Process improvement recommends regular trial production of samples and finding the optimal parameters through data comparison.

The entire production process combines professional knowledge and practical operation experience, which is an important link to ensure the stable luminescence of luminous masterbatch. For producers who are trying it for the first time, it is recommended to start with small batch trial production, gradually accumulate process experience, and improve overall production efficiency.

How to distinguish the performance of luminous masterbatch?

Product quality is the most important part of the manufacturing process. How to detect the performance of luminous masterbatch and ensure that each batch of products meets the standards is a link that every producer needs to focus on.

Performance test items:

- Light luminous intensity test: Use a photometer to measure the luminous intensity of luminous masterbatch under different lighting to ensure that it meets the preset standards.

- Continuous luminous time: Record the time required from the initial reduction of brightness to invisible, usually requiring no less than 3 hours.

- Uniformity test: Use a microscope to check the dispersion of luminous pigments to ensure that there is no obvious agglomeration.

- Weather resistance test: Simulate high temperature and high humidity environment to test the stability of products under extreme conditions.

Quality control method:

- Data recording and comparison: Detailed test data needs to be recorded for each batch of products and compared with quality standards.

- Dynamic monitoring system: Install automatic monitoring equipment on the production line to capture parameter fluctuations in real time.

Practical suggestions:

- Establish a complete product traceability system. From the entry of raw materials, the production process to the delivery of finished products, detailed data is recorded in each link to facilitate future process optimization.

- Organize training regularly to familiarize operators with equipment and quality control indicators, thereby reducing human operating errors and improving the overall quality level.

Through scientific and reasonable testing methods and strict quality control processes, the performance of luminous masterbatches can be effectively distinguished. Ensure the stability and durability of each batch of products, thereby winning the recognition of the market and customers.

Conclusion and future prospects

In general, how to make luminous masterbatches is not only a technology, but also a process that requires continuous improvement and innovation. From principles, material preparation, production process to quality control, every step requires a rigorous attitude and professional technical support. By deeply understanding the basic principles of luminous masterbatches and scientific and reasonable production processes, we can gradually improve the luminous efficiency and durability of products to meet the increasingly stringent requirements of the market.

Future Outlook:

- With the continuous application of new materials and new technologies, the production process of luminous masterbatch will be continuously optimized, and it is expected to achieve greater breakthroughs in energy conservation, environmental protection and efficient luminescence in the future.

- The market demand for luminous masterbatch will prompt enterprises to increase R&D investment and use big data and automation technology to improve production processes.

- Strengthening international standards and certification systems will further enhance the competitiveness of products in the global market.

Summary suggestions:

- Experiments and data accumulation: Continuously conduct small batch experiments and accumulate data to optimize products.

- Equipment and technology updates: Timely introduce efficient equipment and testing instruments to achieve automated production.

- Personnel training: Regularly train production and quality inspection personnel to ensure that the team has the latest knowledge and skills.

- Market feedback: Actively collect and analyze market feedback, timely improve production processes, and meet customer needs.

Through the above detailed steps and professional suggestions, I hope you have a clear understanding and practical ideas on how to make luminous masterbatch. Whether you are a beginner or an experienced producer, you can adjust the process parameters according to actual conditions and continuously innovate and optimize the production process. In the future, the manufacturing of photoluminescent film will be more green, stable and efficient, and will continue to play an irreplaceable and important role in the fields of decoration, identification and security.

Related News

What Does It Mean That FR Reflective Tape Has Passed NFPA2112 and NFPA1971 Certification?

2025-06-11

Top 5 FR Reflective Tape Manufacturers in Europe

2025-06-10

Common Problems and Solutions When Using Reflective Webbing Tape

2025-06-09