How to Make the Photoluminescent Film Last Longer?

2025-04-07

Ysmlite

ysmlite.com

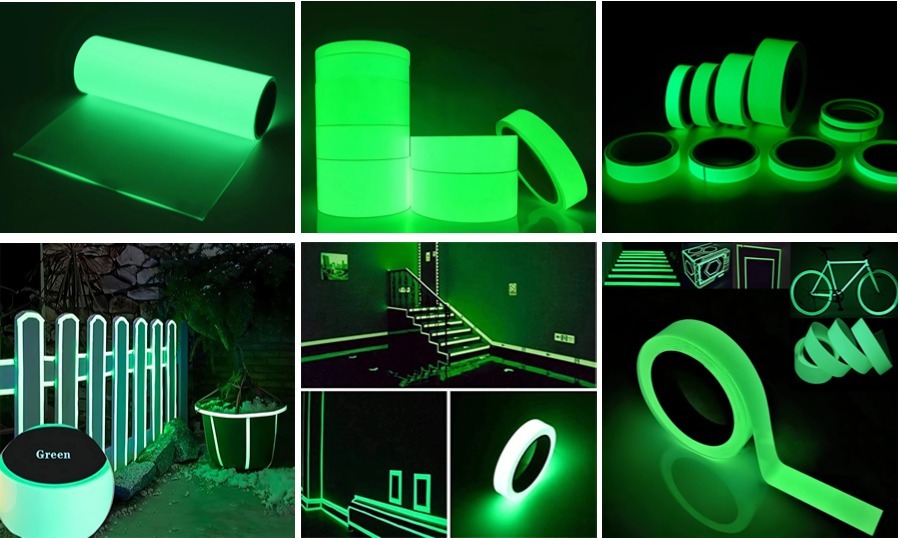

As a sign material that can emit light in a dark environment, luminous film is widely used in safety instructions, decorative design, and advertising display. For users who pursue the best use effect, how to extend the duration of luminous film is a key issue.

What is the luminous principle of luminous film?

To effectively extend the duration of luminous film, you must first understand its basic working principle. Luminous film is usually composed of fluorescent substances and reflective materials. This structure determines its unique luminous properties. In the presence of light, fluorescent substances absorb light energy and store it. When the environment becomes dark, the stored light energy is slowly released in the form of fluorescence, so that the luminous film glows in the dark. This self-luminous process does not require an external power source, so it is energy-saving and environmentally friendly, which is also one of the important reasons why the luminous film is popular.

The fluorescent substance inside the luminous film is the core part of the luminescence. High-quality luminous films usually use energy-storage luminescent materials with a particle size between 5 and 15μm. This precisely controlled particle size can significantly improve the efficiency of light energy absorption while ensuring the continuity and stability of light energy release. On the technical level, the composition and structure of the fluorescent substance directly determine the luminous intensity and duration of the luminous film.

Advanced luminous films also use a multi-layer design, usually including a white protective bottom layer, a plastic luminous film layer, and a plastic translucent protective mask layer. This three-layer structure not only improves the luminous effect, but also enhances the durability of the luminous film. In particular, the surface protective layer can effectively prevent the fluorescent substance from being damaged by the external environment, thereby extending the overall service life.

How long can the luminous effect usually last?

The duration of luminous film is one of the most concerned issues for consumers. According to the performance of common products on the market, the luminous film of general quality can last for 3-8 hours after being fully charged. However, high-end products, especially luminous films using the latest energy storage luminous materials, can last for 12 hours or even longer under ideal conditions.

Many factors affect the duration of luminous film. First, the type and quality of fluorescent substances are the decisive factors. Different fluorescent substances have different energy storage and release capabilities, which directly affect the luminous time and brightness of luminous film. Secondly, the choice of reflective materials is also crucial. High-quality reflective materials can better reflect and transmit fluorescence, effectively extending the luminous time of luminous film.

In addition to the material itself, environmental conditions and usage methods also affect the duration of luminous film. Environmental factors such as temperature, humidity and ultraviolet rays may accelerate the degradation of fluorescent substances. For example, in a high temperature environment, the energy release rate of fluorescent substances will be accelerated, resulting in a shortened luminous time; while at extremely low temperatures, the energy release may become slow. In addition, frequent friction or scratching may also cause the fluorescent substance to fall off, thereby reducing the performance of the luminous film.

It is worth noting that modern high-tech luminous films have adopted innovative technologies to meet these challenges. For example, some luminous films add tourmaline powder to the protective layer, which can release negative ions to neutralize positively charged dust particles in the air, reduce the adsorption of dust on the surface, ensure that the overall luminous performance of the luminous film is not easy to decline, and extend the service life of long afterglow luminescence.

How to choose the luminous material with the longest duration?

Choosing the right luminous material is the key first step to ensure long-lasting luminescence. There are many types of luminous films on the market, among which the luminous film PET luminous film is highly regarded for its excellent performance. This material is made of high-quality PET and is light, thin and durable. It is only a few millimeters thick, but it can withstand the friction and collision in daily use while maintaining stable luminous performance.

When choosing a luminous film, the first thing to pay attention to is the product formula. High-quality luminous films usually contain an appropriate amount of energy storage luminous material (about 20-25 parts), plastic particles (50-60 parts), and auxiliary ingredients such as plasticizers, lubricants and antioxidants. This ratio ensures that the luminous film has excellent luminous performance while maintaining flexibility.

Secondly, attention should be paid to the structural design of the luminous film. Multifunctional luminous films are usually composed of multiple layers, including a base layer, a white protective base layer, a plastic luminous film layer, and a plastic translucent protective mask layer. This structural design not only improves the durability of the product, but also better protects the fluorescent substances inside and prolongs the luminous time.

In addition, high-end luminous films will also add special functional materials such as photocatalyst nano zinc oxide and tourmaline powder. These materials can not only improve the luminous performance of the luminous film, but also purify the surrounding air and reduce the adsorption of dust on the surface of the luminous film, thereby extending the service life of the product. Therefore, when purchasing, you can specifically ask whether the product contains these functional additives.

Finally, don't forget to check the certification and test reports of the product. Luminous films produced by regular manufacturers usually provide technical parameters such as luminous time and brightness decay curve, which can help consumers understand the product performance more accurately.

Will the luminous film fade and wear? Protection and maintenance tips

Luminous films do face fading and wear problems during long-term use, but through proper protection and maintenance, these problems can be significantly delayed. First, we need to understand the main reasons for the fading of luminous films: ultraviolet radiation, chemical erosion, physical friction, and natural attenuation of fluorescent substances.

For ultraviolet radiation, it is recommended to avoid long-term direct exposure to strong sunlight at the location where the luminous film is installed. If it must be used outdoors, you can consider adding a UV protective layer or applying a UV protective agent regularly. Our customer data shows that the luminous performance of luminous films treated with UV protection decays more than 40% slower than that of untreated products.

For chemical erosion, avoid direct contact with luminous films with strong acids, strong alkalis, or detergents containing solvents. When cleaning, it is recommended to wipe gently with neutral soapy water and a soft cloth, then rinse with clean water and dry naturally. This gentle cleaning method can effectively remove surface dirt without damaging the fluorescent layer.

Physical friction is one of the main causes of wear of luminous films. To reduce friction damage, a protective layer can be added to the surface of the luminous film. There are special transparent protective films on the market that can withstand daily friction without affecting the luminous effect of the luminous film. In addition, avoid using hard tools to scratch the surface of the luminous film, which can effectively extend its service life.

Regular inspection and maintenance are also key to maintaining the performance of the luminous film. Perform a comprehensive inspection every three months to observe whether there are areas of fading, peeling or damage. If problems are found, repair or replace them in time to avoid the expansion of the problem area. For places with large areas of use, it is more important to establish a regular maintenance plan.

How do environmental factors affect the duration of luminous?

Environmental factors have a significant impact on the duration of glow in the dark film. Temperature is one of the primary considerations. Studies have shown that luminous films perform best in a temperature range of 15-25℃. At too high a temperature, the energy release rate of the fluorescent substance will accelerate, resulting in a shortened luminous time; at too low a temperature, although the energy release rate slows down, the total luminous time may be extended, but the luminous intensity will be significantly reduced. Therefore, in practical applications, the luminous film should be installed in an environment with a suitable and stable temperature as much as possible.

Humidity is another important environmental factor. High humidity may cause the fluorescent material inside the luminous film to absorb moisture, affecting its luminous performance. Especially in humid seasons or regions, ensure that the luminous film is well ventilated, and use dehumidification equipment to control the ambient humidity if necessary. According to our experimental data, the luminous film has the most stable luminous performance when the relative humidity is kept in the range of 40%-60%.

Lighting conditions directly affect the charging effect of the luminous film. The luminous film needs to absorb enough light energy to continue to glow in the dark. The intensity, spectral distribution and exposure time of natural or artificial light will affect the charging effect. Generally, light sources with higher UV content (such as sunlight or specific LED lights) can provide more effective charging. For best results, it is recommended to ensure that the luminous film receives at least 4-6 hours of sufficient light every day.

Air quality should not be ignored either. Dust and pollutants in the air will adhere to the surface of the luminous film, forming a barrier layer that reduces the absorption and release efficiency of light energy. The tourmaline powder added to high-end luminous film products can release negative ions, neutralize the positively charged dust particles in the air, and effectively reduce the adsorption of dust on the surface. In dusty environments, you can consider cleaning the surface of the luminous film regularly, or choose products with such functional additives.

Professional enhancement tips: Practical methods to extend the duration of luminous film

In addition to selecting high-quality materials and optimizing the use environment, there are some professional tips to further extend the continuous luminous time of luminous film. First, you can consider using multi-layer stacking technology. By stacking luminous films with different characteristics, you can create a luminous effect with longer duration and higher brightness. For example, the bottom layer uses a long afterglow luminous film and the upper layer uses a high-brightness luminous film, which can not only ensure the initial brightness, but also extend the overall luminous time.

Secondly, it is also very important to optimize the charging strategy. Many users ignore the impact of charging quality on the duration of luminous light. For best results, a "segmented charging" strategy should be adopted: 2-3 short-term (about 30 minutes) charging per day is often better than a long-term charging. This is because fluorescent substances have a "saturation effect". After a certain period of time, the marginal benefit of continuing to charge will decline rapidly.

Third, use light enhancers in combination. There are special light-enhancing coating products on the market that can be applied to the surface of the luminous film to enhance its light energy absorption efficiency. These products usually contain special light conversion materials that can convert light waves that are not easily absorbed by fluorescent substances into wavelengths that are more easily absorbed, thereby increasing the charging efficiency by 20%-30%.

Fourth, the innovative "mixed particle size" technology is also worth trying. Traditional luminous films use fluorescent particles of a single particle size, while new technologies use a mixture of fluorescent particles of different particle sizes. Particles with smaller particle sizes (5-8μm) can provide higher initial brightness, while particles with larger particle sizes (10-15μm) can provide longer duration. This combination can create a luminous effect that combines brightness and durability.

Finally, customized luminous solutions are also an effective way to extend the luminous time. According to specific application scenarios and needs, professional manufacturers can customize luminous films with specific formulas. For example, for safety signs, the long afterglow performance can be enhanced; for decorative applications, the brightness and duration can be balanced.

Conclusion: Comprehensive application to create a long-lasting luminous effect

High-quality photoluminescent film products should have high-quality fluorescent substances and reflective materials, multi-layer protection structures, and functional additives such as photocatalyst nano zinc oxide and tourmaline powder. These materials and designs together determine the basic performance and potential luminous duration of the luminous film.

In practical applications, the control of environmental factors cannot be ignored. Appropriate temperature, humidity, lighting conditions and air quality can not only ensure the best performance of the luminous film, but also extend its service life. Regular maintenance and correct protective measures can effectively prevent fading and wear problems.

Going further, professional techniques such as multi-layer stacking, optimized charging strategies, the use of light enhancers, mixed particle size technology and customized solutions can further extend the luminous duration and improve the overall performance based on existing materials.

For individual users and professional users, understanding this knowledge and combining relevant techniques can maximize the continuous luminous time of the luminous film and obtain better user experience and application effects. Whether it is home decoration, commercial advertising or safety signs, long-lasting luminous film can add practical value and visual appeal to our living and working environment.

With the continuous advancement of material science and manufacturing technology, the performance of luminous film products will continue to improve in the future. As an industry leader, YSM will continue to invest in research and development to provide the market with more durable and environmentally friendly luminous solutions to meet the needs of various professional fields.

Related News

How Long Can the Luminous Pigment Powder Glow? How Does It Glow?

2025-04-29

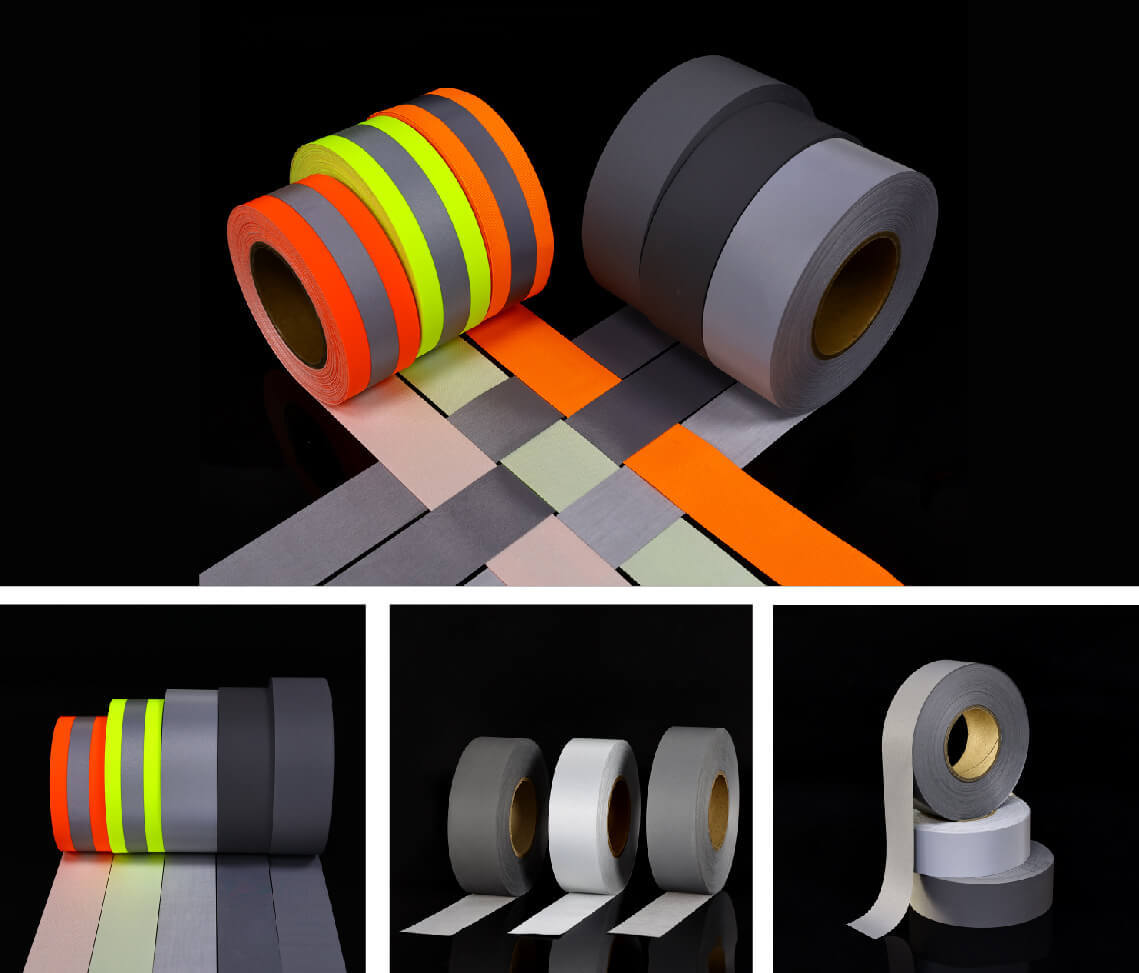

Why Fabrics Are Crucial to Reflective Tape for Clothing Performance

2025-04-25

Reflective Tape for Clothing: The Night Guardian of Safety Workers

2025-04-22