Reflective Tape for Clothing: The Night Guardian of Safety Workers

2025-04-22

Ysmlite

ysmlite.com

At a crossroads late at night, the uniform of traffic policeman Xiao Li drew a silver stream of light under the headlights, and the driver 50 meters away slowed down in advance to avoid it - this inconspicuous flash is a true portrayal of reflective fabric tape saving lives at critical moments. As a safety worker, do you really understand the value of this "invisible armor"?

How does reflective tape for clothing become the "lifeline" of night safety?

On a rainy night with visibility less than 30 meters, the visible distance of ordinary work clothes is only 20-30 meters, while clothing with reflective tape can extend the visible distance to 150-200 meters. This optical miracle comes from micro-prismatic reflection technology: each square centimeter contains more than 5,000 glass beads, which can reflect more than 85% of the incident light along the original path.

How to judge whether the reflective tape for clothing meets industry standards?

Four-step material testing method

- Tear test: high-quality tape should withstand 5kg tension without debonding (in accordance with GB20653 standard)

- Weather resistance test: maintain stable performance in an environment of -20℃ to 60℃

- Reflection intensity: Use HunterLab colorimeter to test, the value must be ≥400cd/lx/m²

- Moisture permeability: ≥5000g per square meter per hour (to ensure comfortable wearing)

A security product buyer once bought low-quality tape for cheapness, and the reflective effect was attenuated by 80% after three months of rainy season. Professional testing agencies recommend: "Choose products that have passed ISO20471 certification. Although they are 15% more expensive, their service life is extended by 3 times."

Comparison of the effects of different reflective tapes in actual combat

| Type | Reflective intensity | Applicable scenarios | Typical cases |

| Engineering grade | 250cd | Construction site | Tower crane commander reflective vest |

| High-strength grade | 500cd | Highway maintenance | Road administration inspection uniform |

| Omnidirectional reflective type | 700cd | Emergency rescue | Firefighting combat uniform |

| Breathable elastic type | 400cd | Outdoor inspection | Power maintenance work clothes |

Learn to use and maintain reflective tape correctly in three steps

The best pasting solution: Form a closed loop at the joints of the human body (such as shoulders + waist + knees) to ensure 360° visibility. Avoid sticking on easily worn parts (such as armpits).

Cleaning tips:

- Water temperature ≤ 40℃, gently hand wash

- Bleach is prohibited (will damage the microprism structure)

- Use a towel to absorb surface water droplets when drying in the shade

Daily maintenance

- Cleaning: Hand washing is best, warm water and neutral detergent, dry naturally in the shade after water;

- Storage: Avoid high temperature and direct sunlight, it is recommended to store curled;

- Regular inspection: Observe whether there is edge or cracking every 3 months, if necessary, fit or replace in time.

How reflective tape for clothing helps safety workers improve visibility

Reflective tape can significantly improve safety in the following scenarios:

- Nighttime construction: The lighting in the construction area is limited, and reflective tape can reflect the light of the car lights back to the driver, so that it can be found from a long distance.

- Highway patrol: When patrolmen are on duty on the shoulder of the road, passing vehicles can notice the people wearing reflective clothing in advance.

- Emergency rescue: Fires, earthquakes and other sudden scenes are often accompanied by thick smoke and gravel. Reflective tape helps rescue team members quickly locate in a chaotic environment.

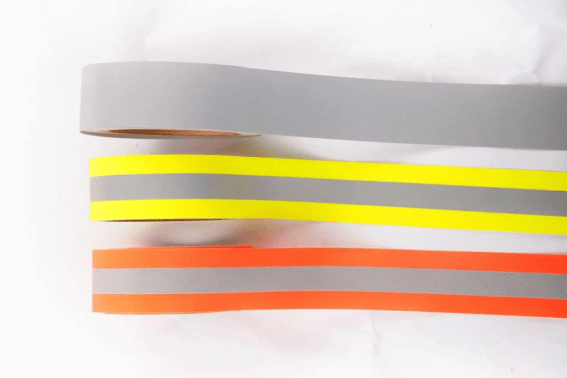

What are the different effects of different reflective cloth tapes?

There are three main types of reflective tapes on the market:

Glass bead reflective tape

- It is composed of tiny glass beads, low price, and good brightness in the short term.

- Disadvantages: poor wear resistance and easy to be scratched.

Microprismatic reflective tape

- The microprism structure is used to refract the incident light multiple times, and the light return efficiency is high.

- The brightness is long-lasting and suitable for long-term outdoor use.

Photosensitive color-changing reflective tape

- Under different light intensities, the color can change to enhance recognition.

- Mainly used in special industries such as mining and chemical industry.

Operation skills

- Glass beads can be selected for low budget, but they need to be replaced more frequently.

- For long-term outdoor or heavy industrial environments, microprismatic products are recommended.

- For special environments, photosensitive types can be considered.

Guide to choosing reflective tape for clothing suitable for safety workers

Combining work environment and budget for comprehensive purchase:

Identify ambient light conditions

- Low illumination at night: give priority to products with high light return coefficient.

- Strong light during the day: pay attention to color contrast and visible range.

Budget control

- Small business or one-time project: glass beads with high cost performance can be selected.

- Long-term bulk purchase: micro prism type is expensive, but more economical.

Brand and service

- Choose a manufacturer with ISO 9001 quality management system certification.

- Request full technical support, such as installation training and after-sales guidance.

Useful list

- Request product samples → On-site testing.

- Check the manufacturer's qualifications → Confirm the certification report.

- Determine the installation tools → Purchase or rent.

Related News

What Does It Mean That FR Reflective Tape Has Passed NFPA2112 and NFPA1971 Certification?

2025-06-11

Top 5 FR Reflective Tape Manufacturers in Europe

2025-06-10

Common Problems and Solutions When Using Reflective Webbing Tape

2025-06-09