Comprehensive Understanding of Luminous Materials

2025-04-18

Ysmlite

ysmlite.com

Imagine that in the dead of night, the edge of your garden path or camping tent emits a warm and soft light to guide you; or in an emergency evacuation, the safety line on the ground is particularly eye-catching in the dark. All this is thanks to "luminous material". It can bring practical safety and add creative beauty.

What is luminous material?

Luminous material, as the name suggests, is a material that "glow in the dark film". Its core mechanism includes two stages:

Excitation stage

When the material is exposed to visible light or ultraviolet light (UV), it "absorbs" photons and excites electrons from the ground state to a high energy state.

Emission stage

After the light source is removed, the electrons gradually return to the ground state and release visible light. According to the different release speeds, it can be divided into:

- Fluorescence: The release time is extremely short (milliseconds), and it will go out as soon as the light source is moved.

- Phosphorescence: The release time is relatively long (minutes to hours), which is the way most luminous powders emit light.

Why is phosphorescence more popular?

- It has a long continuous luminescence time and can be used for emergency signs and night decorations.

- It is easy to prepare, has good weather resistance, and is moderately priced.

The core component is usually a silicate or aluminate matrix doped with rare earth elements (such as cerium Ce³⁺, europium Eu²⁺). These combinations are both stable and non-toxic, and have become the mainstream formula for luminous materials.

Types and applications of luminous materials

According to the material form and matrix carrier, luminous materials can be divided into the following categories on the market:

| Type | Matrix carrier | Advantages | Typical applications |

| Inorganic luminous powder | Silicate/aluminate | Long-lasting luminescence (3–12 hours), strong weather resistance | Safety exit signs, road markings |

| Organic fluorescent dyes | Acrylic acid, polyurethane | Bright colors, high color adjustability, but short life (a few minutes) | Wall art, short-term event decoration |

| Resin luminous paint | Epoxy resin, polyurethane | Easy to apply, good adhesion, waterproof | Outdoor furniture, ship deck |

| Luminous film/sheet | PVC, PET film | Can be cut for thermal transfer and lamination | T-shirt printing, soles, stickers |

| Luminous ink | Ink system (screen printing) | Suitable for mass industrial printing | Electronic product housing, safety labels |

Core application scenarios

- Safety protection: hospital emergency passages, subway platforms, tunnel signs

- Outdoor sports: night running equipment, trekking pole handles, tent lenses

- Home decoration: starry sky murals in children's rooms, stair steps, courtyard paths

- Textile printing and dyeing: fluorescent printed T-shirts, sports vests, fluorescent soles

- Industrial equipment: emergency buttons, control panels, mechanical switches

Each application has different emphases on brightness, weather resistance, adhesion and cost, and comprehensive evaluation is required when selecting.

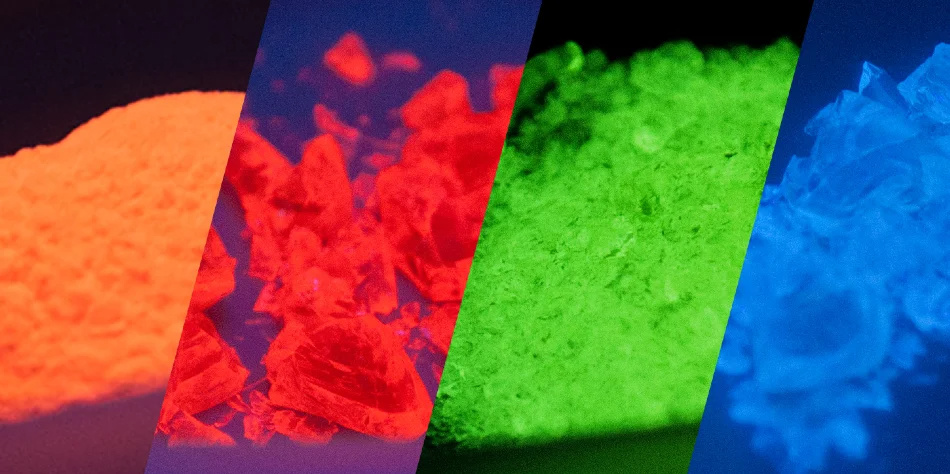

Which color of luminous material is the brightest?

The luminous color of luminous materials is determined by the dopant and the matrix, and the human eye has different sensitivities to different wavelengths. The following is a comparison of common emission colors and brightness:

| Emission color | Emission peak wavelength (nm) | Relative sensitivity of the human eye | Luminous duration | Application suggestions |

| Yellow-green | 520–530 | 90% | 6–12 hours | Safety signs, emergency instructions |

| Green | 532–550 | 80% | 5–10 hours | Outdoor equipment and supplies |

| Blue-green/cyan | 480–500 | 70% | 4–8 hours | Art decoration |

| Blue | 450–470 | 50% | 3–6 hours | Decorative effect, short-term use |

| Pink/orange | 600–650 | 30% | 2–5 hours | Special effects, theme activities |

Tips:

- For the brightest effect, choose yellow-green or green luminous powder and pre-charge it under white light (300–500 lux) for 5–10 minutes.

- In actual projects, the main color can be matched with the decorative color to increase brightness and enrich the visual level.

Is luminous material safe?

Many people worry about "whether the luminous material is toxic or radioactive?" The following is an explanation from several aspects:

Chemical composition is non-radioactive

- Mainstream inorganic silicate/aluminate luminous powders are all stable crystal structures, non-radioactive, and no heavy metals exceed the standard.

Authoritative certification

- EU REACH: Restrict hazardous substances to ensure the absence of phthalates (Phthalates) and heavy metals such as lead and cadmium.

- US CPSIA: For children's product standards, luminous powder is safe to use in toys and children's decorations.

Usage precautions

- Wear a mask and gloves before and after painting to avoid inhaling dust or skin allergies.

- After curing, the surface of the finished product is generally airtight, without dust escaping, and can be safely attached to clothing or home.

Confidence guarantee: Choose products from large manufacturers and regular channels, and check the test report to ensure environmental protection and safety.

Is luminous material suitable for DIY?

Absolutely suitable! Whether you are a novice handicrafter or a senior DIY player, you can easily get started.

Tools and material preparation

- Luminous powder: It is recommended to use inorganic luminous powder with a particle size of 10-20 microns, which is more uniform in luminescence.

- Carrier medium: transparent epoxy resin or acrylic varnish, taking into account both adhesion and transparency.

- Auxiliary tools: disposable plastic cups, stirring rods, fine brushes, syringes, chemical-resistant gloves, masks.

Detailed operation steps

- Substrate pretreatment

- Sand or clean substrates such as wood, glass, and cloth to ensure that there is no oil or dust.

- Mixing ratio

- Luminous powder: resin = 1:1 ~ 1:2 (volume ratio)

- Stir thoroughly for 1-2 minutes until the particles are evenly dispersed.

- Coating or pouring

- Brushing: Apply thin layers multiple times for stable light transmission.

- Pouring: To make a night light or pendant, it can be poured into the mold at one time and cured after removing bubbles.

- Curing and protection

- Curing at room temperature for 12-24 hours (refer to the carrier instructions).

- A layer of transparent protective paint can be sprayed on the surface to improve scratch resistance and wear resistance.

Common problems and solutions

- Many bubbles: add a small amount of defoaming agent, or use a toothpick to pick out bubbles before pouring the mold.

- Not enough light: increase the proportion of luminous powder, or use a stronger light source for pre-charging.

- Separation between layers: do a slight polish between each layer, and keep the surface slightly wet before applying the next layer.

How to choose and use luminous materials?

Before choosing the right material, please answer three key questions: brightness, substrate, and construction method.

Selection according to brightness requirements

- High brightness (safety/emergency): yellow-green inorganic powder, particles 10–20 μm.

- Decorative creativity: multi-color organic dyes, particles can be large or small, and rich colors.

- Outdoor weathering: epoxy resin luminous paint, UV-resistant and washable.

Compatibility of different substrates

| Substrate type | Recommended carrier | Construction suggestions |

| Wood/stone | Epoxy resin, acrylic | Polish the surface and apply in layers |

| Fabric/clothing | Thermal transfer film, screen printing ink | Preheat and dry, 200–220 ℃ hot press for 30–60 seconds |

| Metal/plastic | Polyurethane varnish | Spray or brush, dust-free environment required |

| Glass/ceramic | UV curing resin | UV lamp curing, curing time depends on power |

Construction process comparison

- Brush/spray: flexible, suitable for irregular surfaces.

- Screen printing: high efficiency, mass production.

- Heat transfer: precise pattern, suitable for textiles.

- Casting: best for three-dimensional works and decorative pendants.

Maintenance and life of luminous materials

Luminous materials are not "once and for all", and regular maintenance is required to extend the luminous performance.

Principle of luminous decay

- Each charge and discharge cycle consumes a small amount of luminous active centers (rare earth ions)

- High temperature, ultraviolet rays, and chemical corrosion will accelerate aging

Tips for extending life

Avoid high temperature environment:

- Control the use temperature ≤ 60 ℃;

- Outdoor decoration can add sunscreen coating or shielding.

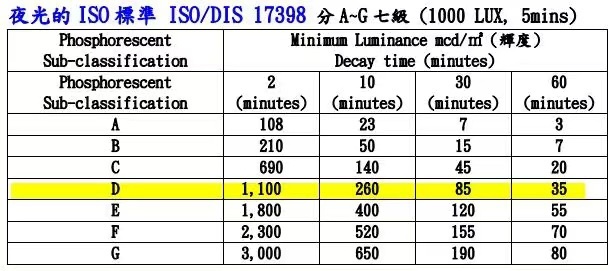

Regular "power replenishment":

- Use 1000 lux white light for 10-20 minutes per month;

- If the project is important, it can be upgraded to UV lamp for 5 minutes of fast charging.

Anti-chemical corrosion:

- Avoid using strong acid and alkali cleaners when cleaning;

- It can be gently wiped with neutral detergent and then rinsed with clean water.

Inspection and repair:

- Check the integrity of the coating once a year;

- If cracks or peeling occur, it can be partially polished and re-coated.

Conclusion

Luminous materials combine scientific principles and creative design, and play a unique value from safety protection to personalized decoration.

You can:

- Choose the luminous color, base and construction process according to your needs

- Follow the steps to easily experience the fun of DIY

- Apply maintenance tips to extend the life of the project

Take action now: choose a suitable luminous powder, prepare the tools, and you can bring the "magic of the night" to your next project!

If you have more questions or want to share your luminous works, please leave a message below, let's communicate and improve together! I wish you light up the night and create surprises.

Related News

What Does It Mean That FR Reflective Tape Has Passed NFPA2112 and NFPA1971 Certification?

2025-06-11

Top 5 FR Reflective Tape Manufacturers in Europe

2025-06-10

Common Problems and Solutions When Using Reflective Webbing Tape

2025-06-09