What Are Rare Earth Luminescent Materials?

2025-04-16

Ysmlite

ysmlite.com

When we walk on the streets at night, or rely on the guidance of street lamps in emergency situations, we often find that luminous films provide us with reliable lighting. The core of all this is inseparable from a magical material-rare earth luminescent materials. Today we will talk about the mystery of this type of material and the revolutionary changes it brings to the manufacture of photoluminescent film.

What are rare earth luminescent materials?

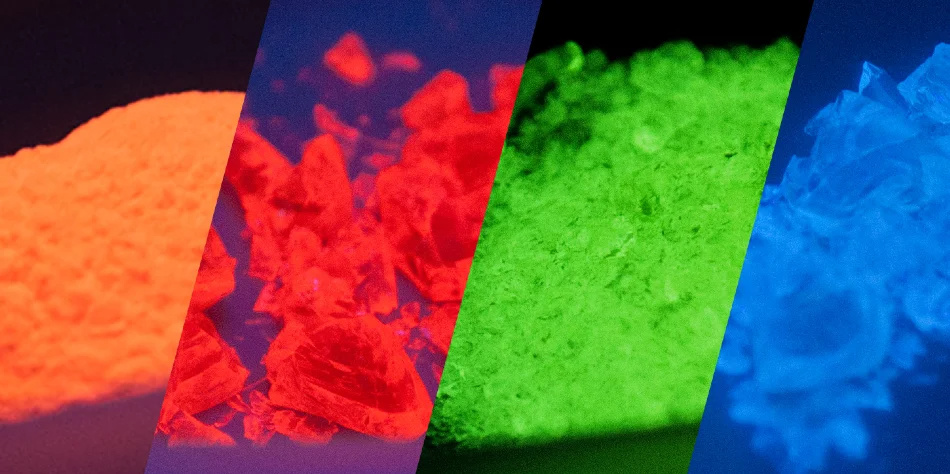

Rare earth luminescent material is a type of photoluminescent material prepared using the unique electronic structure of rare earth elements (such as europium, cerium, ytterbium, etc.). They can release long-lasting light when stimulated by external light or energy, so that the luminous film remains bright in an environment without external light sources.

Main features:

- Long-term luminescence: It has extremely high energy absorption and storage capacity, and can release long-lasting and soft light in the dark.

- Stable and pure color: The light color emitted is stable and pure, and will not fade due to extended use time.

- High temperature resistance and anti-interference: Even in harsh environments, it can ensure stable working conditions.

Scientific principle:

- When the material absorbs external light energy, the rare earth ions are excited to a high energy state, and then release energy in the process of returning to the ground state. This luminescence process is a typical photoluminescence phenomenon. This phenomenon determines the high efficiency and durability of rare earth materials, and provides a reliable luminescence basis for luminous films.

Through a large amount of experimental data verification, rare earth luminescent materials can still maintain their performance in different environments, which also establishes its position in the high-tech industry. Modern scientific and technological research shows that this material is widely used in many fields such as LED, fluorescent display and laser.

Preparation process and key links of rare earth luminescent materials

The preparation of rare earth luminescent materials is a process that requires precision equipment and strict process control, mainly involving raw material purification, chemical reaction, heat treatment, and final surface modification. The following is a step-by-step analysis of each link and the tools required:

Key preparation links:

- Raw material purification

- High-purity rare earth ions are extracted from ores through high-precision chemical extraction methods.

- Chemical precipitation and ion exchange methods are used to remove impurities to ensure the quality of raw materials in subsequent reactions.

- Chemical synthesis

- The purified rare earth elements are mixed with other chemical reagents for reaction to generate preliminary luminescent precursors.

- Common methods include sol-gel method, coprecipitation method and solid-phase reaction method, which can make the reaction more uniform and efficient.

- Heat treatment and sintering

- The reacted materials are heat treated at high temperatures to make the crystal structure of the materials more stable and improve the luminescence efficiency.

- A temperature-controlled high-temperature furnace is used to ensure that the temperature and time of each batch of products are strictly consistent.

Surface treatment and packaging

In order to improve the durability and optical effect of the material, surface modification such as coating, doping and other processes are carried out.

Nanotechnology and coating equipment are used to ensure that the film is uniform, bubble-free and crack-free.

Recommended tools and equipment:

- Precision measuring instruments (such as electronic balances): ensure accurate raw material ratios.

- Temperature-controlled high-temperature furnace: strictly control the heat treatment process.

- High-speed agitator and ultrasonic cleaning machine: ensure the uniformity and purity of the reaction mixture.

Operation suggestions:

- Small-scale test: start with a small batch experiment, record detailed data, and gradually optimize the process flow.

- Data recording and analysis: each step needs to accurately record data, and continuously adjust the formula through analysis.

- Safe operation: strictly abide by the chemical safety operation procedures to ensure the safety of experimental personnel and equipment.

Through the above process flow, production enterprises can effectively improve the luminous efficiency and product quality of rare earth luminescent materials, and lay a solid foundation for the manufacture of luminous film.

Core advantages of rare earth luminescent materials compared with similar materials

To understand the importance of rare earth luminescent materials, we must first see its unique value in the market and technology from its many advantages, and also understand its differences compared with other materials.

Core advantages:

- High luminous efficiency

Rare earth materials can absorb a lot of energy in a short time and release it for a long time, achieving a high brightness effect, which makes the luminous film still appear bright in a dark environment for a long time.

- Strong stability

Even in harsh environments such as high temperature, humidity, and strong radiation, rare earth materials can still maintain stable luminescence characteristics. This environmental stability is unmatched by other materials.

- Environmental protection and energy saving

Due to the high-efficiency energy conversion, rare earth luminescent materials can achieve low energy consumption and high output, which meets the requirements of modern green energy saving.

- Long life

Rare earth luminescent materials still maintain a high luminescence ability under repeated excitation, which is more durable than organic luminescent materials and less prone to attenuation.

Comparison with other materials:

- Organic luminescent materials

Although inexpensive and simple to prepare, organic materials are prone to aging, uneven luminescence, and relatively short life. Rare earth materials show more durable and stable characteristics.

- Traditional inorganic phosphors

Traditional phosphors may experience performance attenuation in high temperature environments, while rare earth materials can better adapt to harsh environments and maintain light efficiency due to their unique crystal structure and thermal stability.

After long-term outdoor use, the brightness attenuation rate of the luminous film using rare earth luminescent materials is less than 20%, while the attenuation rate of traditional materials can be as high as 35% or even more. In practical applications, it is recommended that enterprises make comprehensive optimizations in terms of materials, processes, equipment, etc. based on their own product characteristics and needs, and continuously conduct comparative tests to ensure the performance advantages of the products.

Application of rare earth luminescent materials in luminous films

The core advantage of luminous films is due to the outstanding performance of rare earth luminescent materials. The following will introduce how to efficiently use this material in the manufacturing process of luminous films from a practical operation perspective.

Application steps:

- Raw material preparation and formula design

- According to the expected application scenarios (such as roads, decorations, emergency lighting), a specific formula is formulated to accurately calculate the ratio of rare earth materials to adhesives.

- It is recommended to refer to industry standards and authoritative test reports when designing the formula to ensure the best mixing ratio.

- Stirring and uniform dispersion

- During the mixing process, professional stirring equipment is used for efficient stirring, and ultrasonic vibration is used to ensure that the rare earth luminescent materials are evenly dispersed in the resin.

- The raw materials can be added in multiple times to ensure that the materials are thoroughly mixed to avoid uneven luminescence caused by excessive local concentration.

- Coating and film-forming treatment

- The mixed material is evenly coated on the substrate, and automatic spraying or scraper coating equipment is used to ensure that the thickness of each layer of film is consistent.

- During the coating process, it is recommended to control the ambient temperature and humidity to prevent bubbles and other surface defects.

- High temperature curing and surface modification

- After coating, a temperature-controlled high-temperature furnace is used for curing to ensure that the rare earth material and the substrate are tightly combined.

- Finally, the surface encapsulation process can be used to enhance the weathering and wear resistance of the film surface, so that the product can adapt to various harsh external environments.

Development prospects of rare earth luminescent materials

With the rapid development of science and technology, luminous films and related display technologies are gradually entering a new era of intelligence and energy saving. And rare earth luminescent materials have become one of the core engines of this transformation.

Market demand:

- Increased demand for safety and emergency lighting

The accelerated urbanization process and enhanced safety awareness have led to a significant increase in demand for products such as luminous films and road signs.

- Environmental protection and energy-saving trends

The pursuit of green and energy-saving products by the government and society has driven companies to adopt rare earth luminescent technologies with lower energy consumption and higher efficiency.

Technological innovation direction:

- Intelligent control

Combined with the Internet of Things technology, the brightness of the luminous film can be automatically adjusted to better adapt to different lighting environments.

- New material development

Through doping or structural modification, a new type of rare earth luminescent material that is more efficient and more environmentally friendly is developed.

- Cross-border integration

Combined with laser display, LED and new display technology, the application of rare earth materials in more high-end fields is expanded.

Prospect forecast:

In the future, with the continuous maturity and improvement of the process, rare earth luminescent materials will not only occupy a dominant position in the luminous film industry, but will also expand to the fields of automobiles, aviation, medical care and home smart lighting. Enterprises should pay close attention to the R&D trends of the international market, maintain technological leadership, and thus occupy a favorable position in the competition.

How to purchase and optimize rare earth luminescent materials

In order to ensure that the luminous film products can perform at their best, it is crucial to correctly purchase and reasonably apply rare earth luminescent materials. The following are some specific suggestions:

Purchase points:

- Qualification certification: Confirm that the supplier has authoritative certification and strict quality inspection reports to ensure that the materials meet industry standards.

- Detailed product data: Suppliers are required to provide detailed data reports, including key indicators such as luminous efficiency, weather resistance, and thermal stability.

- Sample trial: Before purchasing in large quantities, you can first purchase a small amount of samples for trial to test the performance in the actual environment.

Usage and optimization suggestions:

- Pay attention to the mixing ratio: Strictly operate according to the recommended ratio to avoid affecting the final product effect due to deviation in the mixing ratio.

- Equipment calibration: Regularly calibrate mixers, high-temperature furnaces and other production equipment to ensure accurate execution of the process.

- Technical training: Arrange technical personnel to participate in training and industry seminars regularly to master the latest processes and optimization methods.

- Continuous feedback: Establish a complete data feedback system, and adjust and optimize product formulas in a timely manner by monitoring test data and market performance.

Tools and resource recommendations:

- Online forums and technical blogs: Pay attention to industry trends and obtain the latest process experience.

- Professional instrument and equipment suppliers: Purchase the latest models of temperature control equipment and high-precision instruments.

- Industry exhibitions and training: Improve the overall technical strength of the team by visiting exhibitions and participating in training courses.

Related News

What Does It Mean That FR Reflective Tape Has Passed NFPA2112 and NFPA1971 Certification?

2025-06-11

Top 5 FR Reflective Tape Manufacturers in Europe

2025-06-10

Common Problems and Solutions When Using Reflective Webbing Tape

2025-06-09