Product classification

Personalized High Quality Luminous Film

Photo Luminescent Tape, glow in the dark sticker

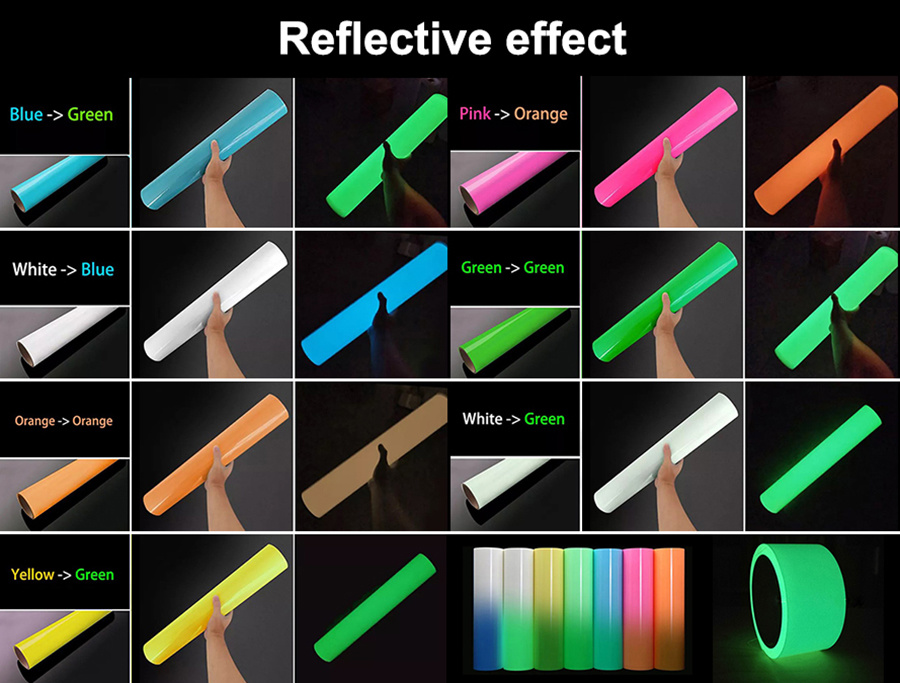

Color: Green or color custom

Material: PET+PVC

Size: 1.22m*45.7mor customized

Customizability: Can be customized, Custom Logo

Sample: Freely Provided

Feature: Eco-friendly

Certification: EN20471 Class II standard, ANSI/ISEA107-2020, Oeko Tex 100

Application: sewing on Safety work wears sports wears leisure decoration bags etc.

Send Inquiry Now Get Free Sample

* Please be sure to leave your correct information so that we can contact you in time!

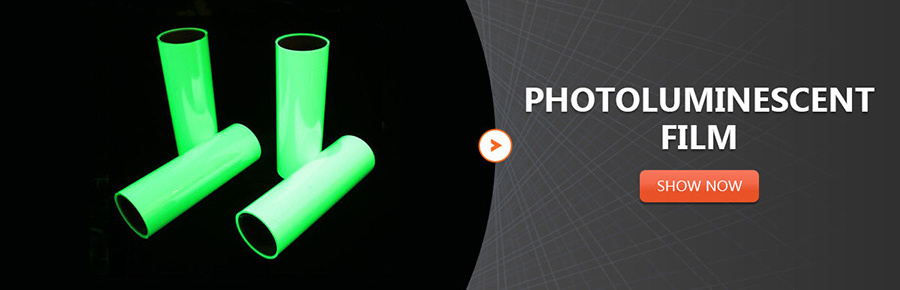

Photoluminescent film is a special film product that combines functional light effects with creative design. It is made of advanced photoluminescent technology. It absorbs energy from natural light or artificial light sources during the day and continuously releases soft cold light at night, achieving eye-catching visual effects without power supply. It is widely used in interior decoration, safety signs, electronic products, advertising creativity, car modification and other fields to meet personalized aesthetic and practical needs.

Custom glow in the dark advantage

Substrate selection

- High-transparency PET base film: It uses high-transparency polyester film (PET) as the base material, with excellent flexibility, tear resistance and weather resistance, and can adapt to curved or special-shaped surface lamination.

- Environmental certification: It complies with RoHS and REACH standards, is non-toxic and radiation-free, and is suitable for safety-sensitive scenes such as home and children's products.

Luminous layer core technology

- Rare earth aluminate luminous powder: An exclusive long-afterglow rare earth material that absorbs light for 5-10 minutes and can continue to glow for 8-12 hours. The brightness is far higher than that of traditional zinc sulfide materials, and the life span is more than 10 years.

- Uniform dispersion process: Through nano-level dispersion technology, the luminous particles are evenly distributed to avoid local dark areas, and the luminous effect is stable and uniform.

Protective and functional coating

- UV anti-aging layer: The surface is covered with an anti-ultraviolet coating to resist yellowing and embrittlement caused by direct sunlight, and the outdoor service life is increased by 50%.

Wear-resistant and scratch-resistant layer: 3H hardness coating effectively resists daily friction and protects the clarity of the pattern. - Adhesive adaptability: Provide removable weak adhesive (suitable for walls and glass) or strong adhesive permanent adhesive (metal, plastic substrate) to meet the needs of different scenarios.

Full process flexible design

- Pattern customization: Support high-definition color printing, hollow engraving, gradient light effect and other processes, compatible with corporate logos, artistic patterns, text slogans, etc.

Size and shape: Can be cut to any size, support special-shaped cutting (such as round, wavy edges, hollow shapes). - Luminous color: Standard blue-green light (wavelength 520nm), optional purple, red and other customized colors, need to confirm the adaptability of the light source in advance.

Advantages of factory direct supply

- Own luminous film factory: equipped with fully automatic coating production line, precision slitting equipment and spectrometer to ensure the consistency of mass production.

- Strict quality control standards: each batch of products passes the light intensity test (≥80mcd/m²), peel strength test (≥2.5N/cm) and high and low temperature cycle test (-20℃~80℃).

- Fast proofing service: provide sample confirmation within 48 hours, support small batch orders (minimum order quantity 10 square meters).

In-depth analysis of material characteristics

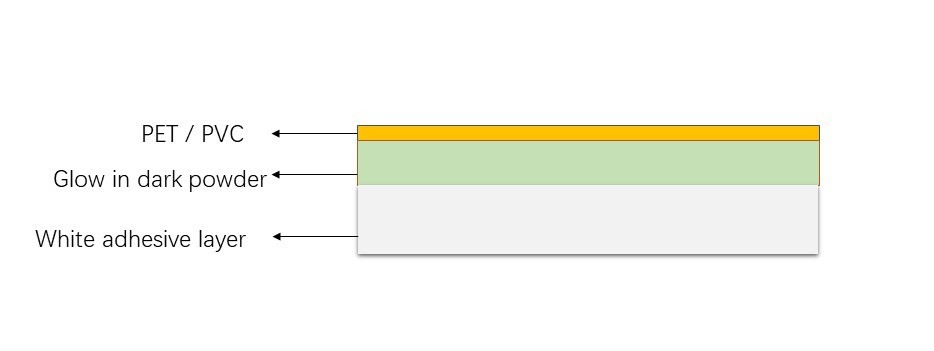

Core material composition

- Substrate: It uses high-strength vinyl (PVC), PET and other highly transparent and wear-resistant materials as the substrate, with excellent flexibility, tear resistance and weather resistance, and can adapt to -30°C to 80°C environment.

- Luminous layer: It uses advanced luminous pigments or photoluminescent materials, which are non-radioactive, non-toxic and harmless, and meet RoHS standards.

- Surface treatment: It is covered with a scratch-resistant and wear-resistant coating to improve UV resistance, waterproofness and chemical corrosion resistance, and the outdoor service life can reach 8-10 years.

Luminous performance parameters

- Excitation time: saturation after absorbing light for 10-30 minutes, and continuous luminescence for 8-12 hours in the dark (bluish-green light effect is optimal).

- Luminous brightness: initial brightness can reach 2000-3000 mcd/m², decaying over time, and still maintaining 30-50 mcd/m² visible brightness after 12 hours.

- Transmittance: daytime transmittance ≥85%, achieving seamless switching between transparent and luminous functions.

Physical performance advantages

- Weather resistance: passed QUV 2000-hour aging test, anti-yellowing, no cracking.

- Adhesive: pressure-sensitive adhesive is used, supports bubble-free pasting, can be removed without leaving residual glue (some models support repeated pasting).

Best Glow in the Dark Film Product

|  |  |

Pvc luminous film | PET luminous film | Acrylic luminous film |

1. According to the luminous time, it is divided into four grades ABCD, with rich colors, matte surface and non-tearable. 2. It has good flame retardant properties and is mostly used in fire escapes. 3. It has good printing performance and can be used for screen printing and solvent-based oil film inkjet printing. 4. Can be cut and divided into customer-required sizes.

| 1. It is divided into four grades ABCD according to the luminous time. The surface is smooth and cannot be torn. 2.It has good computer engraving performance, PET ink must be used for printing. 3.Widely used on the surface of various products, such as door handles, handrails, life-saving supplies, etc. 4.Can be cut and divided into customer-required sizes.

| 1. According to the luminous time, it is divided into four levels ABCD. 2. Have stable physical and chemical properties. 3. Non-toxic, harmless, no radioactive substances, no energy consumption, maintenance-free, easy to install. 4. Supports engraving, painting, and screen printing.

|

Luminescent Film Advantage

-Acrylic and PVC type available, can be screen printed.

-Non-toxic, non-radioactive and has stable chemical properties.

-Yellow and green color and long service life.

-Also emit a very strong luminous effect under low light conditions.

-Durable, environmentally friendly, energy-saving, economical and practical.

-Can be pasted on the surface of various equipment and objects and is easy to use.

-customized according to user needs to enhance brand image and commercial value.

-Used in many fields such as advertising, product packaging, exhibitions, and wall decoration.

-Can give people a novel and unique feeling at night or in dark places, and has a certain indicating effect.

Glow in the dark film market is driven by safety product applications, as they provide safety way guidance system asthey don't need electricity to glow in the dark if they are properly maintained. in emergency situations where there ispower failure the photoluminescent films will immediately light the way to safety even in smoke condition.

The photoluminescent films are most efective in areas that are frequently exposed to light and have shorter periods ofdarkness, like the photoluminescent films are used widely in warehouse where lights are always on which ensures thatthat photoluminescent films will be always charged and would glow in the event of power failures. The restrain tophotoluminescent film market would be that the light energy might only last for few hours.

Frequently Asked Questions and Answers

Q1: How long can the luminous film last?

A: Under normal conditions, it can continue to glow for 8-12 hours after absorbing light for 10 minutes (high brightness for the first 2 hours, and then gradually decay). The specific duration is affected by the ambient light intensity.

Q2: Is the luminous film environmentally friendly and safe?

A: This product has passed the SGS test, does not contain heavy metals and radioactive substances, meets the EN71-3 standard for children's toys, and can safely contact the skin.

Q3: Can it be used in outdoor humid environments?

A: Yes. The substrate is waterproof and the adhesive backing is highly weather-resistant. It can be used for outdoor signs, swimming pools and other scenes for a long time. It is recommended to check the adhesive layer every 2 years.

Q4: How to install the luminous film?

A: Clean the surface of the substrate → tear off the backing paper → align and fit → scrape off the bubbles. Provide a matching installation tool kit (scraper, positioning stickers), support video guidance.

Q5: What is the minimum resolution requirement for customized patterns?

A: It is recommended to provide vector graphics (AI/EPS format) or high-definition bitmaps above 300dpi. Complex patterns require a 0.5mm bleed edge.

Q6: Does it support repeated peeling and pasting?

A: The removable adhesive version supports 3-5 times of non-destructive re-pasting, and the strong adhesive version is one-time use. When removing, you need to use a hot air gun to soften the adhesive layer.

Q7: How long is the customized production cycle?

A: 3-5 working days for standard orders, and an additional 2-3 days for complex processes (such as multi-layer composite light effects).

Q8: Does the installation of luminous film require special technology?

A: The luminous film is flexible and uses a self-adhesive or post-adhesive design, which is easy to install. Usually, you only need to clean the surface of the substrate and then stick it directly. If it is used on curved surfaces or special areas, you can consult our installation guidance service.

Inquiry Now and Get Free Sample >>>

Luminous Film Factory: The Product Guide

Learn the ABC of reflective tape for clothing in wholesale using the Frequently Asked Questions below.

Basic parameters of YSM luminous film

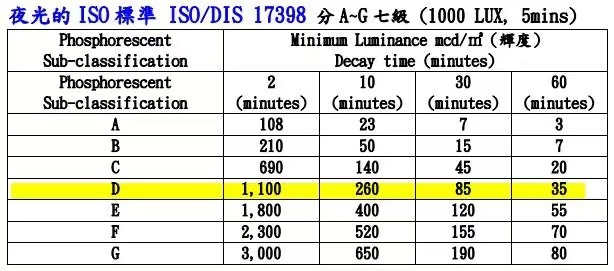

YSMLITE’s ABCD luminous films of different grades have passed the testing of the German DIN67501 standard.

| A | B | C | D | |

| Glowing Time | 4-6h | 6-8h | 8-12h | >12h |

| Regular Size | 1.22m*45.7m/roll | 1.22m*45.7m/roll | 1.22m*25m/roll | 1.22*25m/roll |

Among them, AB grade luminous film is suitable for private advertising, while CD grade luminous film is often used in professional fire protection fields because of its flame retardancy.

What is photoluminescent film?

Luminous film, also known as luminous film, has the properties of self-absorption and self-luminescence. It quickly absorbs light energy when there is a light source, thereby releasing energy in a dim and lightless environment, lighting the way forward, and providing warnings to people walking in the dark. and pointing effect. As a soft plastic luminescent film, the back of the luminous film contains self-adhesive and release paper. It is non-toxic and harmless and does not contain any radioactive elements. It has various colors, high luminous brightness and long service life. It can be pasted on various devices or item surface.

Application fields of glow in the dark film

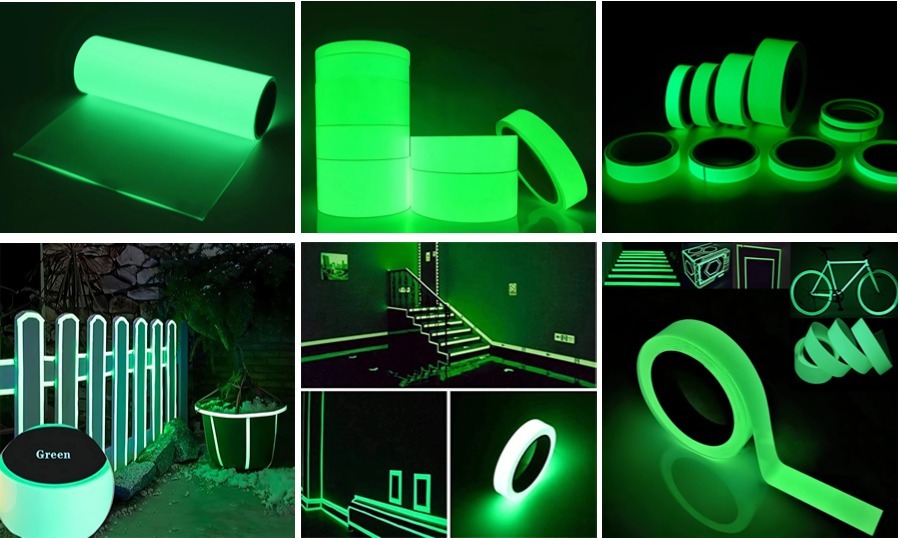

The glow in the dark film absorbs enough natural light during the day, or when exposed to light for at least half an hour, it will emit light in the dark. Long lasting, enables objects to be seen clearly in low visibility conditions. The light storage film is made of polyester film that is environmentally friendly, highly waterproof, non-radioactive and non-toxic.

Therefore, the luminous film can not only be used in traffic signs, fire signs and danger signs in public places, but also can be used to make beautiful home decorations by yourself.

In public building

For example, in entertainment venues and public places (such as hotels, corridors, office buildings, theaters, warehouses, cabins, underground passages, etc.), the application of luminous films greatly increases the safety of these places.

In your individual home

It can be cut into the required pattern and used for home decoration and embellishment, or affixed to switches, phones, handles, electrical appliances, etc., as well as stationery, toys, and sporting goods to increase the fun of the home. The luminescent film can also be used as a substrate to emit light, giving people a novel and unique feeling at night or in dark places, and has a certain indicating effect.

Different standard of luminescent film

YSMLITE's luminous film can emit light for 4-12 hours. According to the light-emitting time and the usage scenario, it can be divided into four grades ABCD. Among them, grade AB has a shorter light-emitting time of about 4-8 hours. It is cheaper and suitable for civilian use. Advertisement; CD grade has a longer luminous time of 8-12+ hours and is more expensive because there is flame retardant on the surface. It is suitable for professional commercial and fire-fighting places. Customers can choose different styles of luminous films according to their needs. Welcome to send us information for inquiry.

YSM's luminous film can emit light mainly because it uses special photoluminescent materials. These materials can store energy in the molecular structure after absorbing light sources (such as sunlight, indoor lighting), and slowly release energy in a dark environment to produce visible light, thereby achieving a luminous effect.

Luminous principle:

Absorbing light and storing energy: The photoluminescent pigments in the luminous film can absorb the light energy of natural light or artificial light sources and convert it into energy storage inside the molecules.

Slow release: When the external environment becomes dark or the light source disappears, the stored energy will be slowly released in the form of light, producing a visible continuous luminous effect.

Long-lasting luminescence: The specially designed luminous film can absorb light and emit light repeatedly, and the duration can reach several hours, depending on the intensity of the light source and the duration of energy storage.

Material characteristics:

Environmental protection and safety: YSM's luminous film materials are environmentally friendly and non-toxic, and meet many international safety standards.

High brightness and long-term luminescence: Compared with ordinary luminescent materials, YSM luminous film has higher brightness in the dark and longer luminescence time.

What are the advantages of YSM luminous film?

Efficient light absorption and long-lasting luminescence

· Quick absorption of light source: YSM luminous film can quickly absorb natural light and artificial light sources and store energy.

· Long-term luminescence: It can continue to glow for several hours in the dark, and the luminescence time is long and stable, ensuring that users can get sufficient visibility in low-light environments.

High brightness

· High brightness display: YSM luminous film uses high-quality photoluminescent materials, with significant luminous effects, and can be clearly seen even in completely dark environments.

Environmentally friendly and safe

· Non-toxic materials: The materials used in YSM luminous film have passed a number of international environmental standards, such as OEKO-TEX and RoHS, to ensure that the product is harmless to the human body and the environment.

· Recyclable: The materials of YSM luminous film are recyclable and meet the environmental protection concept of sustainable development.

Strong durability

· Washable: The luminous film can still maintain its luminous effect after multiple washings, has excellent durability, and is suitable for long-term use.

Good weather resistance: YSM luminous film can withstand the test of various climatic conditions, is not easy to fade or age, and ensures its durability in outdoor environments.

Diverse applications

· Wide applicability: Applicable to a variety of products, such as clothing, footwear, luggage and safety protection equipment, with extremely high practical value.

· Combined with decorative and functional: Not only does it enhance the beauty of the product, but it also provides additional security for nighttime activities, outdoor sports and safety protection.

Thin and light

· Good comfort: The luminous film material is flexible and thin, suitable for clothing and accessories, and does not affect the comfort and flexibility of wearing.

Storage of photoluminescent paper

Keep in warehouse where is ventilated, dry and cool with temperature from 18 to 28 degree and relative humidity between 40% and 60%.

Advantage of Ysmlite glow in the dark film factory

·Easily cuttable and shape, easy to print on it

·Excellent weather, acid, heat resistance

·Fast charging and long luminescent

·Competitive cost in dealing and maintenance

1.We provide customized service for reflective fabric, hologramlogo at front side, also printing logo at back side.Due to there haskinds of quality product in the market, make the logo to promotethe brand and anti-counterfeit labels,meanwhile guarantee theproduct quality.

2.OEM service is available.What support can we give our customers?

·Provide test report copy with customer's company name

·Sign cooperation agreement

·Rebate based on sales

·Hot selling products are guaranteed to be in stock in our warehouse

·Share the cost of developing customers,such as exhibition

3.Why choose us to be business partner?

·We are the manufacturer with more 25 years production and export experience

·Our product is eco-friendly and complied with certificate such as Oeko Tex 100EN20471,ANSI/ISEA 107-2020,NFPA2112 and UL

·Fast supply capacity, because we have the stock

·High quality after-sales service to solve after-sales problems promplty and quickly

Keyword: