What Is Luminous Film? Its Manufacturing Process and Application

2025-04-02

Ysmlite

ysmlite.com

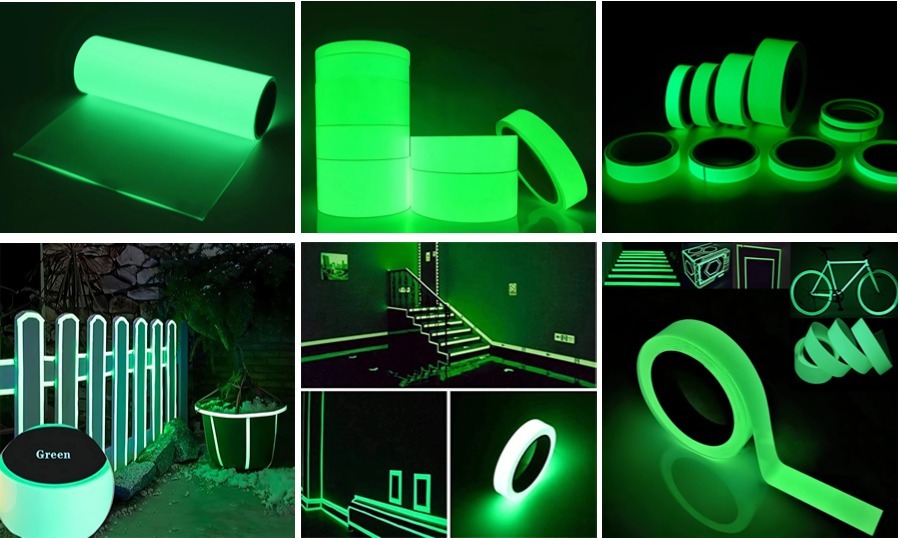

Luminous film is a special material that can absorb and store light energy under the irradiation of a light source, and then release visible light in a dark environment. This high-tech functional film does not require power or batteries, and works on the principle of photoluminescence, providing energy-saving and environmentally friendly lighting solutions for many industries. Market data shows that the global photoluminescent film market is expected to grow from US$233.9 million in 2023 to US$407.98 million in 2030, with a compound annual growth rate of 8.3%.

Basic concept of luminous film

Luminous film, also known as light storage film or photoluminescent film, is a special material that can absorb and store light energy under the irradiation of a light source, and then release visible light in a dark environment. This phenomenon is called photoluminescence, and it does not require heating of the material to occur. The basic principle of luminous film is to use special rare earth elements to activate the material, so that it has the ability to store light energy and slowly release it in the dark.

The luminous process of luminous film can be divided into two stages: light energy absorption stage and light energy release stage. In the light energy absorption stage, the luminous powder molecules in the luminous film absorb the energy of external light sources (such as sunlight, indoor lighting), and the electrons are excited to a higher energy level; when the external light source disappears, these excited electrons will gradually return to the original energy level state, while releasing visible light, which is the "luminescence" phenomenon that we can see with our naked eyes.

Luminous film has very low requirements for activation conditions. When ordinary fluorescent lamps are used as light sources, the light intensity only needs 25LX to activate. The light intensity of general building environments can reach 50-60LX, so sunlight, ordinary lighting, and even indoor environmental reflected light can be used as effective excitation light sources. This low activation threshold characteristic makes luminous film an ideal passive luminescent material in various environments.

What is the difference between luminous film and fluorescent film?

Many people often confuse luminous film with fluorescent film. Although they both have luminous properties, their principles and application scenarios are significantly different. Understanding these differences is essential for choosing the right material.

The main difference between luminous film and fluorescent film lies in their luminous principle and duration. The principle of fluorescent film is that the fluorescent color is visible under the excitation of the light source, but the fluorescence becomes invisible immediately after the light source is removed. That is to say, fluorescent materials can only emit light when illuminated by an external light source, and the luminescence phenomenon stops immediately once the light source is removed. This makes fluorescent film more suitable for use in environments with light sources, mainly relying on its bright colors to attract attention.

In contrast, the characteristic of luminous film (photoluminescent film) is that it can continue to emit light for a long time after being excited by the light source and the light source is removed. This luminous time is determined by the amount and properties of the luminous powder, and is usually divided into two types: long-term (long afterglow) and short-term (short luminous time). High-quality luminous film, such as Juliang luminous film, can continue to emit light for more than 8 hours at a time. This feature makes luminous film particularly suitable for application scenarios such as emergency evacuation signs, safety signs and night instructions.

From the perspective of material composition, luminous film is activated by rare earth elements and processed by alkaline earth aluminate, silicate, and acrylic materials. It has the characteristics of non-toxicity, non-radioactivity, and stable chemical properties. Fluorescent materials are usually made of different fluorescent dyes or pigments, with different chemical properties and environmental adaptability.

In practical applications, glow in the dark film is particularly conspicuous under the illumination of light sources, so it is more suitable for use in daytime and is used in occasions requiring high brightness and high visibility. Luminous film plays its greatest value in dark environments, providing continuous visual guidance at night or in power outages.

What are the manufacturing processes and materials of luminous film?

The manufacturing of luminous film is a precise process that requires the use of specific materials and equipment to ensure the quality and performance of the final product. Understanding these manufacturing processes and material compositions is of great significance for evaluating the quality of luminous film products.

Main material composition

Luminous film is mainly composed of the following key materials:

- PET film: As a basic carrier, its thickness is usually between 0.008mm-0.025mm. PET film provides good flexibility and strength, allowing the luminous film to be applied to a variety of complex surfaces. This ultra-thin substrate is one of the key factors that distinguish modern luminous films from traditional luminous materials with a thickness greater than 0.5mm.

- Luminous powder: This is the core luminous material of the luminous film. It usually uses high-quality luminous powder treated with nanotechnology, mainly from high-quality brands such as Italy or Germany. The quality of the luminous powder directly determines the luminous effect, brightness and durability of the luminous film. High-quality luminous powder is usually made of alkaline earth aluminate or silicate materials activated by rare earth elements.

- Resin: High-quality resins from German brands are usually selected as adhesives to evenly distribute and fix the luminous powder on the PET film. The quality of the resin affects the flexibility, durability and oxidation resistance of the luminous film, and is a key factor in ensuring the long-term stability of the product.

Manufacturing process

The preparation method of the luminous film mainly includes the following key steps:

- Material preparation: Prepare PET film of appropriate thickness, luminous powder treated with nanotechnology and high-quality resin. The selection and pre-processing of materials are crucial to the quality of the final product.

- Mixing and dissolving: Mix and dissolve the luminous powder and resin thoroughly to ensure that the luminous powder particles are evenly dispersed in the resin. This step requires precise control of the mixing ratio and mixing time to ensure the uniform distribution of the luminous powder and avoid agglomeration that affects the luminous effect.

- Coating process: The mixed solution is evenly coated on the PET film. The uniformity of the coating directly affects the luminous effect of the final product. The control of coating thickness is also a key factor affecting the performance of the luminous film, which requires precise equipment and process control.

- Baking and curing: Put the coated material into the coating machine for baking, and the temperature is controlled between 100°C-210°C. This step makes the luminous powder and resin firmly attached to the PET film to form a stable luminous film material. Precise control of temperature and time is crucial to the durability and performance stability of the product.

- Cutting and processing: According to different application requirements, the luminous film material is cut into strips of different widths, usually between 0.15mm-5mm. This step requires advanced machinery and cutting technology to ensure smooth edges and accurate dimensions.

In actual production, the manufacture of high-quality luminous film also requires a strict quality control system, including raw material testing, process parameter monitoring, semi-finished product inspection and finished product testing. Only through a strictly controlled production process can luminous film products with stable performance and reliable quality be produced.

Performance characteristics and advantages of luminous film

High-quality luminous film has a variety of unique performance characteristics and advantages, which makes it stand out in many application scenarios. Understanding these characteristics is essential for choosing the right luminous film product.

Core performance characteristics

- Ultra-thin and soft: The thickness of high-quality luminous film is usually between 0.008mm-0.025mm, which is much thinner than traditional luminous materials (usually thicker than 0.5mm). This ultra-thin feature gives it excellent softness and flexibility, and can adapt to various complex surfaces and shapes, greatly expanding its application range.

- Low activation conditions: Luminous film has very low requirements for activation conditions. When ordinary fluorescent lamps are used as light sources, the light intensity only needs 25LX to activate. The light intensity of a general building environment can reach 50-60LX, so sunlight, ordinary lighting, and even reflected light from indoor environments can be used as effective excitation light sources. This low threshold activation property ensures that the luminous film can work effectively under various lighting conditions.

- Long-term luminescence: High-quality luminous films such as Juliang luminous films can continue to glow for more than 8 hours after absorbing light once, ensuring reliable visual guidance in long-term power outages or dark environments. This long-lasting luminous property makes it an ideal material for safety signs and emergency evacuation systems.

- Rich color selection: Modern luminous films can provide a variety of luminous colors, including green, blue, yellow, etc., to meet the visual needs and aesthetic requirements of different application scenarios. Luminous films of different colors have different luminous properties and visual effects, which can be selected according to specific application requirements.

Significant advantages

- Excellent chemical stability: Luminous films have good oxidation resistance and acid and alkali resistance, enabling them to maintain stable performance and long service life under various environmental conditions. Even in some harsh industrial environments or outdoor conditions, high-quality luminous films can maintain stable luminous performance.

- Strong tensile strength: Compared with traditional luminous materials, modern luminous films have stronger tensile strength, reducing the risk of breakage or damage during application. This feature is particularly important for application scenarios that need to withstand certain mechanical stress.

- Safe and environmentally friendly: High-quality luminous films do not contain harmful heavy metal elements or chemicals, are non-toxic, harmless, non-radioactive, non-flammable, and non-explosive, and fully meet modern environmental protection and safety requirements. This allows luminous films to be safely used in various occasions, including children's toys and personal items.

- Good processing performance: Luminous films have excellent printability and computer engraving performance, and can be secondary processed as needed, such as printing, cutting, hot pressing, etc., to meet various complex design requirements. This good processing performance provides designers and manufacturers with greater creative space.

- Energy-saving and environmental protection: Luminous films do not rely on power or batteries to emit light, and are a sustainable and cost-effective lighting alternative, especially suitable for emergency indication systems and low-energy lighting solutions. In the current global context of energy conservation and emission reduction, this feature gives luminous films a significant environmentally friendly advantage.

By making full use of these performance advantages, luminous film has shown great application potential in the fields of safety signs, decorative design, textile materials, special effects and emergency lighting.

Application of luminous film in different industries

Due to its unique luminous properties and excellent physical properties, luminous film has been widely used in many industries. The following are the main application scenarios and actual cases of luminous film in different industries:

Safety signs and emergency evacuation

One of the most important applications of luminous film is safety signs and emergency evacuation instructions. In emergency situations such as power outages or fires, the light emitted by luminous film can clearly guide people to emergency exits and safe assembly points. This application is crucial to strengthen evacuation procedures and minimize risks in dark conditions. Common applications include:

- Fire safety signs and signs

- Ship safety signs and emergency evacuation route instructions

- Building emergency exit signs

- Safety indication systems for underground passages and tunnels

These applications not only improve the efficiency of evacuation in emergency situations, but also provide reliable visual guidance when conventional lighting systems fail, greatly improving the level of safety assurance.

Home decoration and daily necessities

The beauty and practicality of luminous film make it an ideal material for home decoration and daily necessities:

- Dark light indication of daily objects such as door handles, switches, and telephones

- Creative wall decoration and ceiling design

- Decorative effects such as the starry sky and the moon in children's rooms

- Nighttime visual indication of clock dials and home appliance control panels

The application of luminous film in the home environment can not only provide practical night guidance functions, but also create unique visual effects and artistic atmosphere, meeting people's dual needs for the aesthetics and functionality of living space.

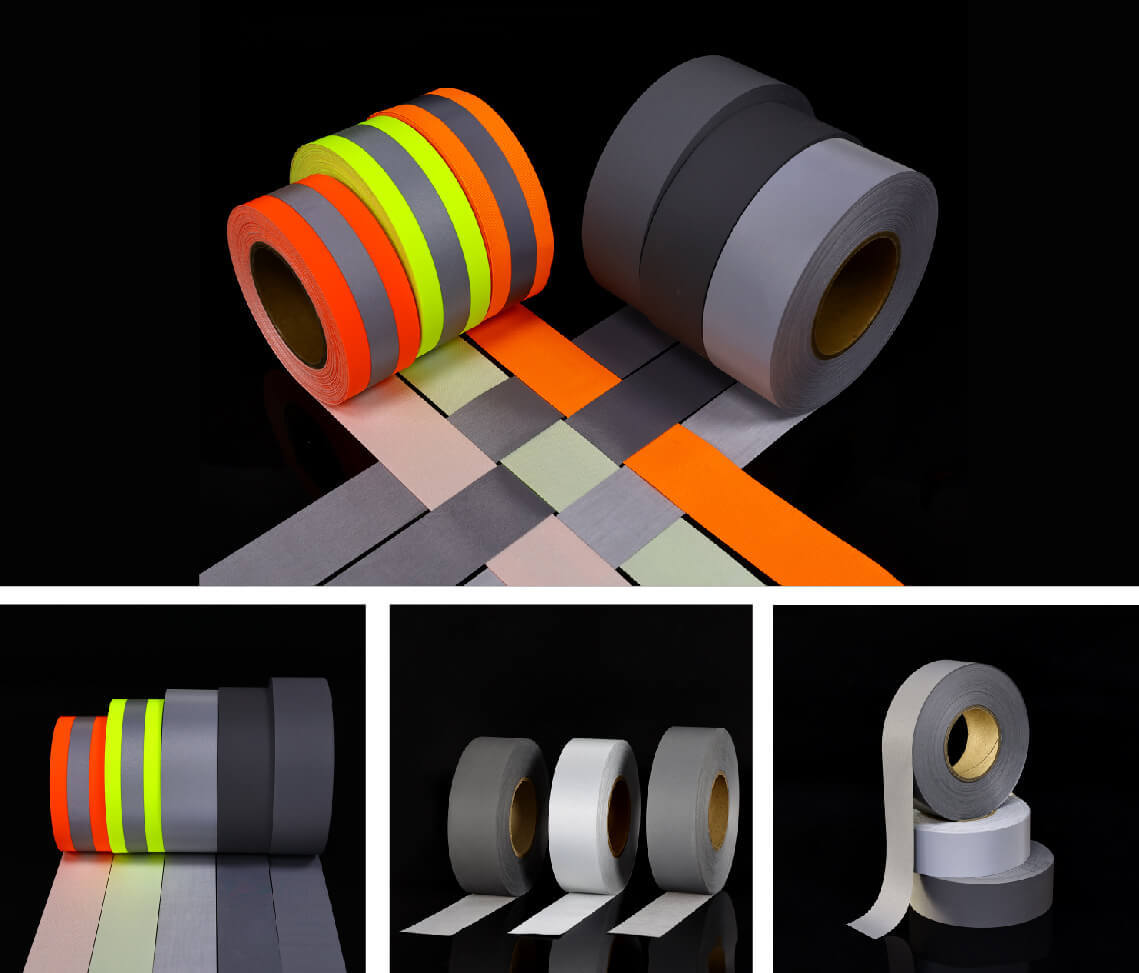

Textile and clothing industry

Ultra-thin luminous film can be processed into luminous yarn and combined with other materials for the textile and clothing industry:

- 0.15MM-0.5MM luminous yarn is mixed with nylon yarn and polyester yarn to make special textile materials

- Used in high-end textiles such as weaving, thread belts, drawing, knitting, embroidery, etc.

- Production of safety work clothes and reflective logos

- Nighttime visible elements of sportswear and outdoor equipment

- Special design effects of fashion clothing

These applications have greatly expanded the functionality and design possibilities of textiles, provided new creative space for fashion designers, and provided a higher level of safety for specific occupations and activities.

Entertainment and special places

The application of luminous film in entertainment and special places creates a unique experience for users:

- Special atmosphere creation of entertainment venues (such as bars and discos)

- Nighttime path guidance and decorative effects of theme parks

- Seating instructions and safety channel signs of theaters and cinemas

- Safety tips and decorative elements of amusement facilities

These applications not only enhance the beauty and uniqueness of the venue, but also enhance the user experience while ensuring safety, creating a differentiated advantage for entertainment venues.

Business and Advertising

The application of luminous film in the field of business and advertising is constantly innovating:

- Billboards and trademarks visible at night

- Creative display materials for special promotions

- Luminous effect design of product packaging

- Eye-catching elements for exhibitions and exhibitions

These applications help brands stand out in the competitive market, attract consumers' attention through innovative visual effects, and enhance brand memory and product added value.

Special Industry Applications

In addition to the common applications mentioned above, luminous film also plays an important role in some special industries:

- Safety indication systems in mining and underground workplaces

- Marking of marine equipment and underwater facilities

- Critical identification of medical equipment in power outages

- Emergency indication systems for military and defense facilities

These applications make full use of the stable performance of luminous film in extreme environments, providing reliable protection for safe production and emergency response in special industries.

With the continuous advancement of technology and the development of people's creativity, the application field of luminous film will continue to expand, bringing innovative solutions to more industries.

How to choose high-quality luminous film?

Choosing the right high-quality luminous film is essential to ensure the success of your project. Here are the key factors and practical suggestions to consider when purchasing luminous film:

Key purchasing factors

Luminous performance evaluation

- Brightness: High-quality luminous film should have a high initial brightness, so that it provides sufficient visibility immediately after the light source is removed. It can be evaluated by comparing with a reference sample in a dark room after activation under a standard light source.

- Luminous storage time: High-quality luminous film such as Juliang brand can continue to glow for more than 8 hours after fully absorbing light once. When purchasing, the required luminous duration should be determined according to the application requirements.

- Decay curve: Understanding the brightness decay curve of the luminous film can help evaluate its performance at different time points. High-quality products are usually brighter in the first 1-2 hours, and then slowly decay.

Material quality inspection

- Substrate thickness: Choose a PET film of appropriate thickness according to the application requirements, usually between 0.008mm-0.025mm. For applications that require extremely high flexibility, thinner materials should be selected.

- Luminous powder quality: High-quality luminous film uses high-quality luminous powder treated with nanotechnology, usually from well-known brands such as Italy or Germany. This can be evaluated by asking the supplier about the source and technical specifications of the luminous powder.

- Resin composition: High-quality resin determines the durability and stability of the luminous film. High-quality products usually use imported resin from Germany. The quality of the resin will affect the service life and environmental adaptability of the product.

Physical performance considerations

- Softness and flexibility: Choose a luminous film with appropriate softness according to the complexity of the application surface. The softness of the material can be evaluated by feel and bending tests.

- Tensile strength: For applications that need to withstand tension, it is important to choose a luminous film with high tensile strength. You can ask the supplier to provide tensile strength test data.

- Weather resistance and chemical resistance: Evaluate the durability of the luminous film in the expected use environment, including oxidation resistance and acid and alkali resistance. For outdoor or special environment applications, products with corresponding weather resistance certification should be selected.

Practical purchase suggestions

Clear application requirements

First determine your specific application scenario and needs, including:

- Required luminous time (short-term or long-term)

- Use environment (indoor, outdoor, special environment)

- Installation surface type (flat, curved, fabric, etc.)

- Desired visual effect (luminous color, brightness requirements)

Clarifying these needs will help you narrow down your choices and avoid purchasing unsuitable products.

Request samples for comparison

Request samples from different suppliers for intuitive comparison:

- Test the luminous performance of different samples under the same conditions

- Evaluate the softness, thickness and feel of the material

- Test the performance of the sample in a simulated actual application environment

Testing the sample in person is the most direct way to choose a high-quality luminous film, which can avoid the risks of relying solely on product descriptions.

Check certification and test reports

High-quality luminous film products usually have:

- Environmental safety certification (such as non-toxic and harmless certification)

- Luminous performance test report

- Durability test data

- Related international standards compliance certification

These documents can objectively prove product performance and are an important basis for evaluating product quality.

Consider cost-effectiveness rather than pure price

Evaluate the total cost of ownership rather than just looking at the initial purchase price:

- Although the initial cost of high-quality luminous film may be higher, it has a longer service life

- Consider installation convenience and subsequent maintenance costs

- Weigh the best balance between performance and price

From a long-term use perspective, choosing a product of appropriate quality is usually more economical than choosing the cheapest product.

Choose a professional manufacturer

Cooperating with a professional luminous film factory like Ysmlite that specializes in luminous film manufacturing has obvious advantages:

- Rich industry experience and expertise

- Customized solutions can be provided according to specific needs

- More complete technical support and after-sales service

Professional manufacturers can usually provide more professional product recommendations and more reliable quality assurance, providing stronger support for the success of your project.

By following the above purchasing guide, you can choose the most suitable high-quality luminous film product for your project to ensure the best application effect and usage experience.

Conclusion

As a functional material with unique photoluminescent properties, luminous film has been widely used in safety signs, home decoration, textiles and clothing, entertainment venues and other fields due to its advantages such as ultra-thin, soft, anti-oxidation, acid and alkali resistance and strong tensile strength. Unlike fluorescent films that only emit light under light, luminous films can continue to emit light after the light source is removed, providing a reliable solution for visual guidance in dark environments.

From the perspective of material composition, high-quality luminous film is mainly composed of PET film, luminous powder treated with nanotechnology and high-quality resin, and the product's performance and quality are ensured through precise manufacturing processes. The continuous innovation of these materials and processes also provides a solid foundation for the future development of luminous film.

The unique advantages of luminous film are its low requirements for light sources, long luminous time, no need for power supply, environmental protection and safety, making it an ideal material for safety signs and emergency evacuation systems. Especially in power outages or emergencies, the continuous luminous ability of luminous film can effectively guide people to find safe exits and reduce potential risks.

As the global demand for safety and energy conservation and environmental protection increases, the luminous film market is expected to maintain an annual compound growth rate of 8.3% and reach a scale of US$407.98 million by 2030. This growth will be accompanied by the in-depth practice of technological innovation, application expansion and sustainable development concepts.

For users who need to purchase luminous films, clarifying application requirements, evaluating luminous performance, checking material quality and physical properties, considering cost performance and choosing professional manufacturers such as Ysmlite are key steps to ensure high-quality products. Only by choosing suitable luminous film products can its value and advantages in specific application scenarios be fully utilized.

In short, as a modern functional material that integrates safety, practicality and aesthetics, luminous film is providing more and more innovative solutions for our life, work and special environmental needs. With the continuous advancement of related technologies and the continuous expansion of application fields, the future development prospects of luminous films will be broader.

Related News

How Long Can the Luminous Pigment Powder Glow? How Does It Glow?

2025-04-29

Why Fabrics Are Crucial to Reflective Tape for Clothing Performance

2025-04-25

Reflective Tape for Clothing: The Night Guardian of Safety Workers

2025-04-22