Why Choose Fire Suits With Flame Retardant Reflective Tape?

2025-03-29

Ysmlite

ysmlite.com

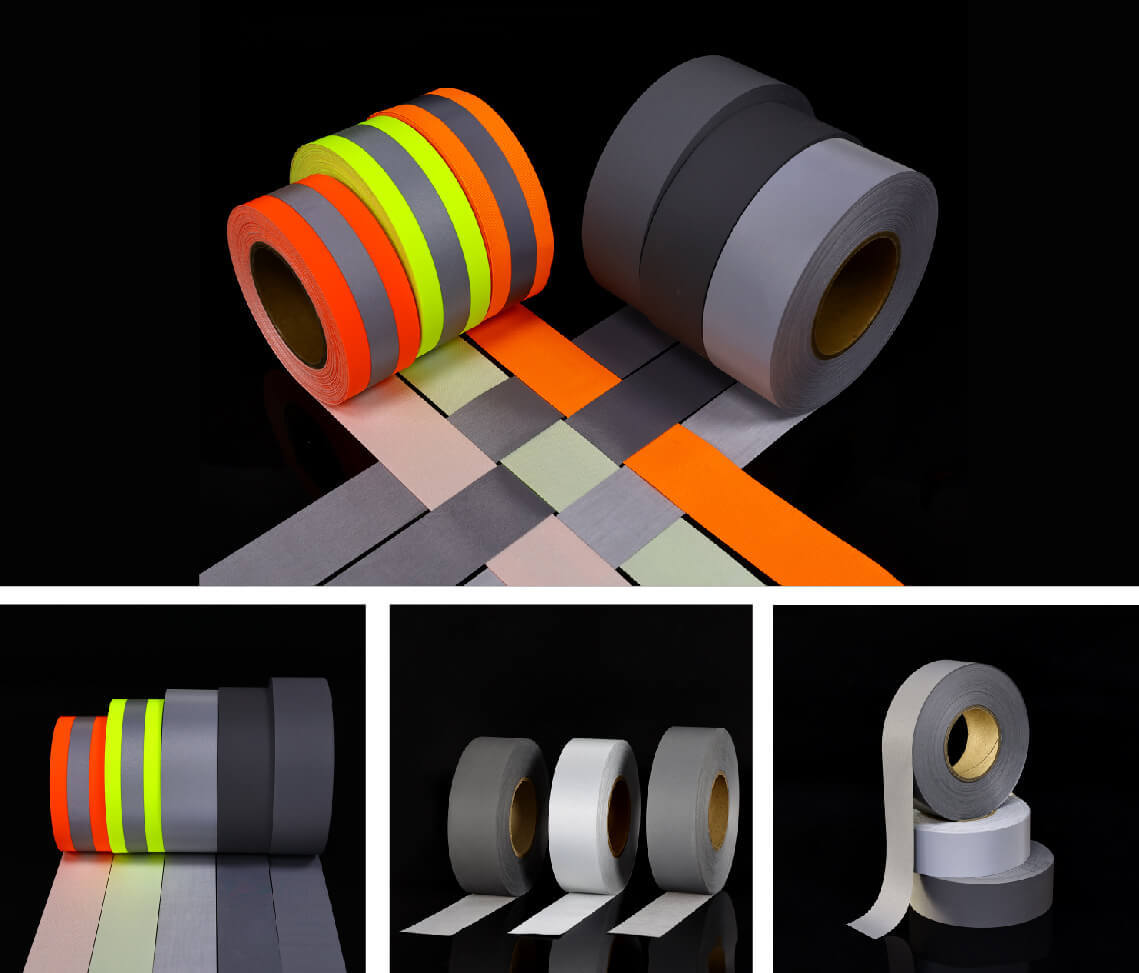

As a life guarantee for front-line rescuers, the safety and functionality of fire suits are crucial. In recent years, flame retardant reflective tape, as an important part of fire suits, can not only effectively reduce the risk of injury caused by fire, but also provide timely visual reminders at night or in low light environments with its excellent flame retardant and reflective properties. The use of this tape can greatly improve the comprehensive protection capability of fire suits, so it has attracted much attention from the industry.

From my practical experience, the use of fire retardant reflective tape can not only improve the safety factor of firefighting uniforms in fire scenes, but also perform well in daily training and maintenance. After participating in fire equipment improvement projects many times, I deeply understand the important role of advanced technology in improving equipment performance.

Manufacturing process and process analysis: How to produce high-quality flame-retardant reflective tape?

High-quality flame-retardant reflective tape is inseparable from strict manufacturing processes and advanced process control. The entire production process can be divided into the following main stages, each of which has unique technical requirements and quality standards:

Raw material selection and ratio

High-quality flame-retardant reflective tape first needs to use polymer materials and flame retardants that meet international safety standards. Commonly used materials include polyester, polyamide and their composites, each of which has different heat resistance, flexibility and wear resistance. Experimental data show that adjusting the ratio of flame retardants to polymer materials can reduce the burning speed of the tape in the flame by 20%-30%, effectively extending the protection time.

Mixing and coating process

After the raw materials and flame retardant are evenly mixed, the mixture is evenly coated on the substrate through precision coating equipment. This process requires high equipment precision, and the temperature and pressure control must be accurate and in place, otherwise it may cause uneven thickness of the tape, which in turn affects the flame retardant effect. The digital monitoring system can provide real-time feedback on production data, helping technicians to adjust process parameters in a timely manner to ensure that each batch of products meets the expected standards.

Embedding technology of reflective particles

In the production process of tape, embedding reflective particles is a key step to ensure the reflective performance of the product. Through high-tech spraying or dipping processes, micron-level reflective particles are evenly dispersed on the surface of the tape, so that it can effectively reflect light at night or in low-light environments. Related tests have shown that this technology can increase the reflective intensity by 15%-25%, greatly improving the visibility of firefighters during night rescue.

Curing and shearing

After coating, the tape is cured to ensure that all chemical reactions are completely completed, so that the tape has long-term and stable flame retardant properties. Finally, the tape is cut into a predetermined width and length by an automated shearing device, and each roll of product undergoes strict quality inspection to ensure that the product size, thickness and reflective uniformity meet the design standards.

I have participated in multiple production improvement projects in my actual work, and successfully improved the stability and durability of the product by continuously optimizing the process and equipment configuration. After adopting the new digital production line, our product qualification rate has increased by nearly 30%, and the production efficiency has also been greatly improved. These technical improvements have laid a solid foundation for the market competitiveness of flame-retardant reflective tapes.

What is the difference between flame-retardant reflective tapes with different substrates?

The substrate of FR reflective tape directly determines its physical properties and scope of application. Common types of substrates include polyester, polyamide and new composite materials, which have obvious differences in flame retardancy, wear resistance and flexibility:

Polyester substrate

Polyester is widely used in flame-retardant reflective tapes because of its excellent high temperature resistance and water resistance. It can not only withstand high temperature environments, but also maintain stable physical properties under humid conditions, and is suitable for fire suits that need to be exposed to outdoor environments for a long time. However, polyester has relatively poor flexibility, so it needs to be used in conjunction with other materials in certain applications that require high flexibility.

Polyamide substrate

Polyamide substrate has good wear resistance and elasticity, and is suitable for occasions that require frequent movement and intense exercise. Its unique fiber structure enables it to better maintain stability and integrity when subjected to friction and stretching. However, since its high temperature resistance is slightly inferior to polyester, it is usually necessary to add additional flame retardants in the production of flame-retardant reflective tape to improve its fire resistance.

Composite substrate

The new composite material combines the advantages of polyester and polyamide, and achieves a good balance in flame retardancy, wear resistance, elasticity and water resistance. Experimental data show that the composite substrate product has a flame retardant effect that is about 20% higher than that of the traditional single substrate, and has better tear resistance. This material is currently becoming an important choice for high-end firefighting uniforms.

In actual production, according to different use environments and design requirements, the reasonable selection of substrate combinations is the key to improving product performance. Enterprises can refer to international authoritative data and market feedback, and combine their own R&D conditions to select the right material combination in a targeted manner, so as to ensure safety performance while taking into account the durability and comfort of the product. For more detailed information on the differences in substrates, please refer to the manufacturing process and process analysis.

How to maintain and wash safety clothing with flame-retardant reflective tape?

Correct maintenance and washing methods are the key to ensuring that fire suits can perform their best protective performance for a long time. Fire suits are prone to wear and stains after experiencing fire, high temperature and intense exercise, especially the fireman reflective tape part. The following are detailed maintenance and cleaning recommendations:

Pre-use inspection

Before each wear, be sure to check the overall condition of the fire suit, especially the tape part. Observe for signs of shedding, wear or chemical damage. It is recommended to record the inspection results in the maintenance log so that the product status can be regularly evaluated.

Initial cleaning

Use a soft brush and vacuum cleaner to first remove dust and large particles of impurities from the surface of the fire suit. Pay special attention to the tape area to avoid additional damage caused by rough tools. This step helps remove loose dirt attached to the clothing, laying a good foundation for subsequent washing.

Gentle washing

When washing fire suits, be sure to use neutral detergents and control the water temperature to no more than 40 degrees Celsius. High temperatures or strong detergents may destroy the reflective particles and flame retardants in the flame-retardant reflective tape, thereby reducing its effectiveness. It is recommended to use professional equipment, such as a high-precision temperature-controlled washing machine, to ensure that the water temperature and washing time are within a reasonable range.

Drying and storage

After washing, the fire suit should be air-dried naturally, avoiding direct sunlight and high temperature environments. Sun exposure may cause the tape color to fade and the reflective performance to decrease. It is recommended to store in a dry, well-ventilated place, and check the storage conditions regularly to ensure that long-term storage will not affect product quality.

Regular maintenance and records

It is recommended to conduct a comprehensive inspection of the fire suit after each use, and arrange for professionals to perform in-depth maintenance regularly. Establishing a maintenance record file can help determine the aging trend of the product, detect problems in time and take replacement measures. In my experience, the use of a scientific maintenance process can extend the service life of the fire suit by more than 30%.

With these practical suggestions, you can effectively extend the service life of fire suits and ensure that the equipment is always in the best condition during each rescue operation. For more specific operation steps, please refer to the detailed process described in the actual case sharing section.

Experience in installing, maintaining and maintaining flame-retardant reflective tapes

In the process of designing and producing fire suits for many years, I have accumulated a lot of valuable practical experience. The following is a typical case that shows how to significantly improve the overall performance of fire suits through scientific process improvements and strict maintenance processes:

Project background and preliminary evaluation

In a certain project, the customer reported that the original fire suits had problems with tape shedding and reduced reflective effect in high-temperature fires. After comprehensive testing, we found that the flame retardant performance of the tape material decreased during long-term use due to frequent cleaning and high-temperature environment. Based on this problem, we launched a product improvement plan to upgrade the tape material, production process and subsequent maintenance methods in an all-round way.

Process improvement and technical adjustment

In the new plan, we first adjusted the raw material ratio, increased the proportion of high-efficiency flame retardants, and introduced a new composite substrate to make the product more stable at high temperatures. Then, by improving the coating process and introducing precision embedding equipment, the reflective particles are more evenly distributed. Actual test data shows that the fire resistance time of the new product has been extended by nearly 25%, and the reflective intensity has been increased by more than 20%.

Installation and on-site operation

Special tools and process manuals were used during the installation of the improved fire suits. The staff was strictly trained to ensure that each process was operated in accordance with the standard. On-site data records show that the new fire suits performed well in the simulated fire scene test, and all indicators met or even exceeded the expected requirements.

Maintenance process and long-term maintenance

In order to ensure the long-term and stable operation of the product, we have developed a complete set of detailed maintenance plans. After each use, the operator will clean, inspect and record the fire suits according to the established steps. Regular maintenance not only extends the product life, but also effectively prevents safety hazards caused by aging of the tape. Practice has proved that after adopting this series of measures, the overall service life of the fire suits has been extended by nearly 30%, while reducing maintenance costs.

Feedback and continuous improvement

After the project was implemented, customer feedback significantly improved the durability and safety performance of the fire suits. We regularly collect field usage data and customer opinions to continuously improve product design and process flow.

The application value of flame-retardant reflective tape in fire suits

To sum up, flame-retardant reflective tape is not only a technological innovation in modern fire suits, but also an important protective measure to ensure the safety of rescuers. Through strict manufacturing processes, scientific material selection and effective post-maintenance, the excellent performance of this tape in flame retardancy and reflection has been widely verified.

In the future development, with the continuous advancement of new materials and intelligent manufacturing technology, we have reason to believe that flame-retardant reflective tape will play a greater role in protective equipment such as fire suits, and continue to improve the safety performance and service life of equipment.

Flame-retardant reflective tape is not only a product, but also represents a commitment of science and technology to safety protection. In the future, we will continue to be committed to technological innovation and product optimization, so that every rescuer can have more protection and more safety at the fire scene. May technology and safety go hand in hand to escort every rescue operation!

Related News

How Long Can the Luminous Pigment Powder Glow? How Does It Glow?

2025-04-29

Why Fabrics Are Crucial to Reflective Tape for Clothing Performance

2025-04-25

Reflective Tape for Clothing: The Night Guardian of Safety Workers

2025-04-22