How Long Can the Luminous Pigment Powder Glow? How Does It Glow?

2025-04-29

Ysmlite

ysmlite.com

When night falls, the lights of the city gradually go out, and only the starry sky and the deep darkness guard this world. However, on roads, subway platforms, hospital evacuation passages, and even home decorations and art installations, luminous pigment powder has become a "bright light in the dark night", quietly flashing in the dark night, bringing us safety, convenience and aesthetic experience.

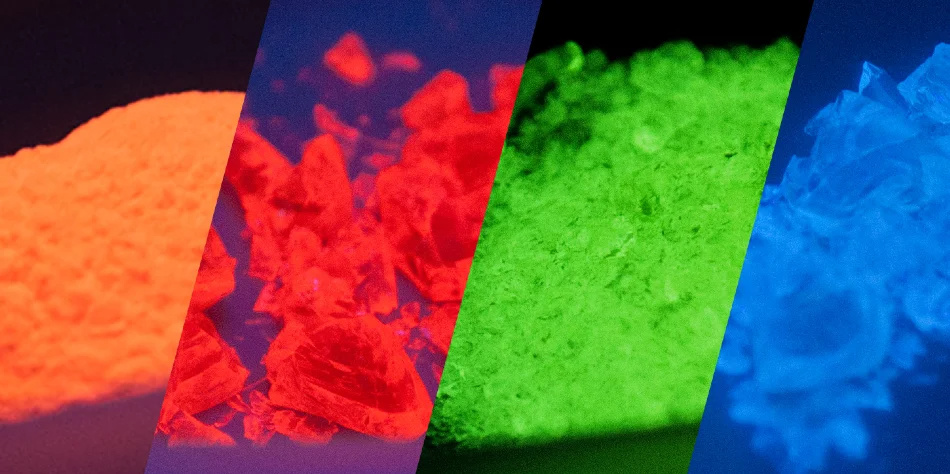

As a leader in photoluminescent film, strontium aluminate-based luminescent pigment powder (SrAl₂O₄:Eu²⁺, Dy³⁺) has rapidly occupied the market with its high brightness and long afterglow performance since its launch in 1993, becoming the first choice for emergency signs, functional coatings and creative crafts. This article will deeply analyze the whole process of "light storage-luminescence" of luminescent pigment powder from material evolution, luminescence principle to actual measurement duration, and combine authoritative literature and industrial testing to provide actionable optimization strategies and real cases to help you optimize the luminous effect in professional or DIY scenarios.

Evolution of luminous pigment powder: from zinc sulfide to strontium aluminate

Early zinc sulfide era

ZnS:Cu phosphor powder: widely used in the 1970s, the luminescent color is blue-green, the initial brightness is about 50-100 mcd/m², and the duration is only 30 minutes to 1 hour. Due to insufficient efficiency and stability, it has been gradually replaced by higher performance materials.

Revolutionary breakthrough of strontium aluminate

Nemoto Research Institute, Japan (1993): SrAl₂O₄:Eu²⁺,Dy³⁺ phosphor was prepared for the first time, with an initial brightness of 200–300 mcd/m². After 10 minutes of excitation under visible light conditions, it can continue to emit light for more than 10 hours in a completely dark environment (sciencedirect.com, pubs.acs.org).

The success of this material is due to the doping of Eu²⁺ to provide the main luminescent ions, and Dy³⁺ to create deep traps to delay release, so that electrons slowly fall back in the dark, achieving long-lasting luminescence.

Industrialization and formulation optimization

Particle size control: Studies have shown that luminescent powder with a particle size of 5–10 µm can take into account both luminescence peak and persistence; nanoscale (<500 nm) is used for biomedical labeling, with a higher surface area and response speed (researchgate.net).

Co-doping technology: In addition to Eu/Dy, there are also studies on adding Nd³⁺ and Gd³⁺ to further optimize the trap distribution, which can achieve a slight extension of the afterglow time (~5–10%) at a molar ratio of 0.001–0.01.

Photoluminescence mechanism of luminous pigment powder

The luminescence of luminous pigment is essentially the phenomenon of phosphorescence under photoluminescence:

Electron excitation and trap formation

Eu²⁺ absorbs 300–400 nm ultraviolet light or visible light, and electrons transition to the conduction band.

Some electrons are captured by defect energy levels such as Dy³⁺ and enter the "trap" to maintain the excited state.

Slow release and visible light release

After the environment is dark, the electrons gradually escape from the trap and return to the ground state under the dual effects of thermal stimulation or spontaneous transition.

Each fall back releases energy, which appears in the form of 520 ± 30 nm green light, forming an "afterglow".

Double exponential characteristics of the decay curve

Fast decay stage (Fast Decay): In the first 5–10 minutes, the brightness drops rapidly by ~50%.

Slow decay stage (Slow Decay): After 10 minutes, it enters a slow decay, and the curve has a double exponential characteristic, which can last for dozens of hours.

Revealing the luminous duration: experimental data and decay curve analysis

Standard laboratory measurement: recording by integrating sphere photometer

Experimental conditions: The sample is irradiated under a 365 nm UV lamp for 15 minutes for saturated light storage; the luminous intensity decay is measured using a Labsphere FHS-02 integrating sphere photometer.

Typical data:

- Initial brightness: 250 mcd/m²

- After 5 minutes: 120 mcd/m² (about 52%)

- After 30 minutes: 45 mcd/m² (about 18%)

- After 1 hour: 20 mcd/m² (about 8%)

- After 8 hours: 1.2 mcd/m² (about 0.5%)

- After 12 hours: 0.4 mcd/m² (close to the lower limit of human vision).

ImageJ darkroom shooting method: easy to implement in small and medium-sized laboratories

In a controlled darkroom, use a high-sensitivity camera to shoot the sample every 30 minutes for a total of 12 hours.

Use the ImageJ "Time Series Analyzer" plug-in to extract the image mean grayscale value and convert it into a relative brightness curve.

Experimental data shows that after 20 minutes of white light excitation with a light intensity of 50 lux, the brightness decays by about 70% in the first hour, and then it can emit light slowly within 10 hours.

Comparison of academic research data

Montes-Frausto et al. prepared SrAl₂O₄:Eu,Dy nanoparticles by combustion synthesis. The study showed that after 10 minutes of UV excitation, the afterglow can last for more than ~16 hours, and even 48 hours of faint afterglow was detected in the laboratory environment (researchgate.net).

The study showed that the Eu²⁺/Dy³⁺ ratio was 0.01/0.02 mol, the trap distribution was optimal, and the half-life of the slow decay phase (t₁/₂(slow)) was about 1,500 seconds (25 minutes), but the subsequent slow decay tail could last for several days.

Professional testing: Reliable method for measuring the luminous performance of luminous powder

| Testing method | Advantages | Limitations | Recommended tools |

| Integrating sphere photometer | Accurately measure total luminous flux and brightness curve | High price, requires professional optical laboratory | Labsphere FHS-02 |

| Spectral intensity tester | Obtain luminous wavelength distribution and time domain information | High cost, high requirements for sample preparation cleanliness | Otsuka ISA-220 |

| Darkroom time-lapse photography method | Low cost, universal equipment | Accuracy is affected by camera sensitivity and software analysis | High-sensitivity camera + ImageJ |

| Thermal release curve (TL) | Analyze deep trap energy level distribution | Requires thermal control equipment and professional analysis software | TL instrument + Fityk |

Practical skills for extending the duration of luminous powder

Efficient pre-lighting process

Alternately irradiate the sample with 365 nm UV-LED (power ≥ 5 W) and high color rendering (CRI ≥ 90) white light for 10 minutes each time to quickly fill shallow and deep traps.

Powder particle layer ratio

Mixed according to a 7:3 particle size distribution (large particles: 5–10 µm, small particles: <1 µm), taking into account both initial brightness and long tail persistence, it is recommended to add 12%–15% loading to the polymer matrix.

Surface sealing protection

Use a thin layer of silane coupling agent (such as 3-aminopropyltriethoxysilane) to improve resistance to water vapor and oxidation. Experiments show that the brightness decay rate can be reduced by 10%–15%.

Substrate and layered structure design

For floor or wall applications, first spray a 300–500 µm luminous functional layer, then cover with a transparent polyurethane topcoat to protect the luminous powder and improve mechanical wear resistance.

Common misunderstandings: Avoid those "professional-looking" but useless suggestions

Myth: The more frequent the light is charged, the shorter the battery life.

Truth: Frequent short-term excitation will not damage the luminous powder. Reasonable alternating use of UV and white light can evenly excite shallow traps and deep traps, improving the overall afterglow quality.

Myth: The higher the addition amount, the better.

Truth: More than 20% addition amount is likely to cause particle agglomeration, which in turn reduces luminous uniformity and mechanical properties. The optimal load is 10%–15%.

Myth: The higher the room temperature, the stronger the luminescence.

Truth: High temperature will accelerate the electron escape rate, resulting in rapid decay. The best storage and use temperature is 20–30°C, avoid high temperature environment.

The technological evolution of luminous pigment powder is not only a breakthrough in material science, but also brings us both practical and aesthetic value. From laboratories to subway stations, from museums to human body imaging, the secret of continuous luminescence lies in the fine control of microscopic trap energy levels and macroscopic processes.

For more technical support or sample testing, please contact the Ysmlite engineering team. We will continue to provide you with professional and reliable luminous solutions.

Related News

What Does It Mean That FR Reflective Tape Has Passed NFPA2112 and NFPA1971 Certification?

2025-06-11

Top 5 FR Reflective Tape Manufacturers in Europe

2025-06-10

Common Problems and Solutions When Using Reflective Webbing Tape

2025-06-09