What Are the Types of Luminous Film

2025-03-13

Ysmlite

Ysmlite.com

Introduction to luminous film

In the field of safety protection and reflective clothing, luminous film, as a key material, plays an important role in improving night visibility and ensuring personnel safety.

Photoluminescent film is a functional material that can emit light by itself or absorb light energy in a dark environment. It has a wide range of applications, covering industrial safety, traffic instructions, emergency rescue, and reflective clothing. As a manufacturer of YSM reflective materials, we are well aware of the importance of product quality and technological innovation in improving night safety. Luminous film can not only significantly enhance visibility, but also has the advantages of environmental protection and energy saving. It is an indispensable high-tech material in the field of safety protection.

Types and classifications of luminous films

According to different production processes, material compositions and application scenarios, glow in the dark vinyl roll can be classified from the following dimensions:

Classification by process

- Self-luminous luminous film

Using chemiluminescence technology, it can emit light autonomously after absorbing ambient light, usually without additional excitation light source, and is suitable for use in environments without external lighting for a long time.

- Fluorescent coating luminous film

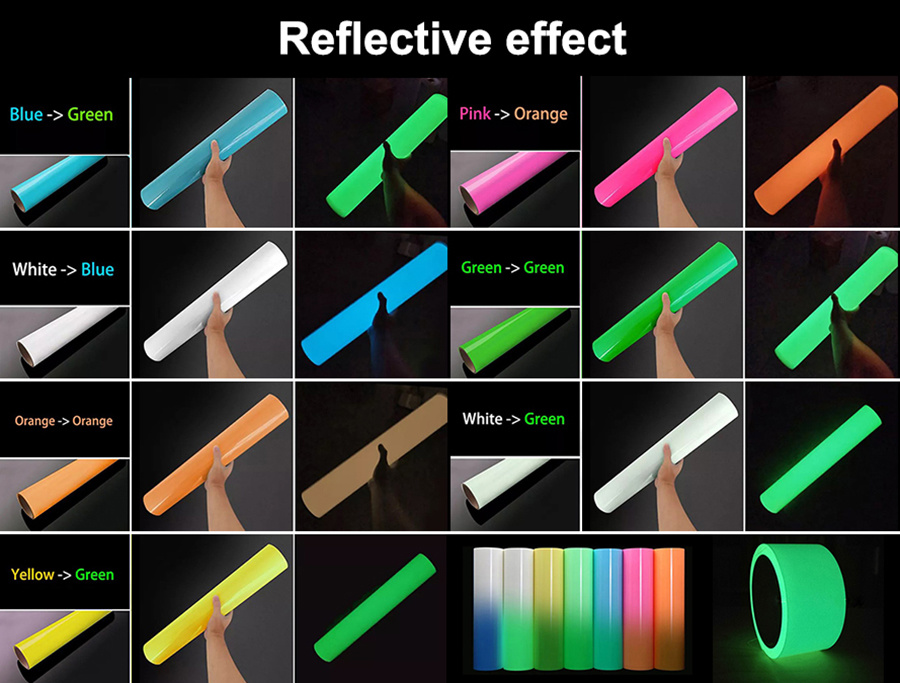

By coating fluorescent materials on the substrate, it emits bright light when exposed to ultraviolet rays or light of a specific wavelength, and is often used in traffic signs and clothing materials.

- Photoluminescent luminous film

Using the principle of photoluminescence, it absorbs light energy first and then slowly releases it in the dark, with a long afterglow time, which is suitable for emergency and safety indication purposes.

Classification by material base

- Polyester-based luminous film

It has excellent wear resistance and flexibility, and is suitable for fields such as clothing and outdoor advertising.

- PVC/PET-based luminous film

Emphasizing waterproof and anti-corrosion properties, it is often used in traffic signs and industrial environments, and can work stably in harsh environments.

Classification by application scenario

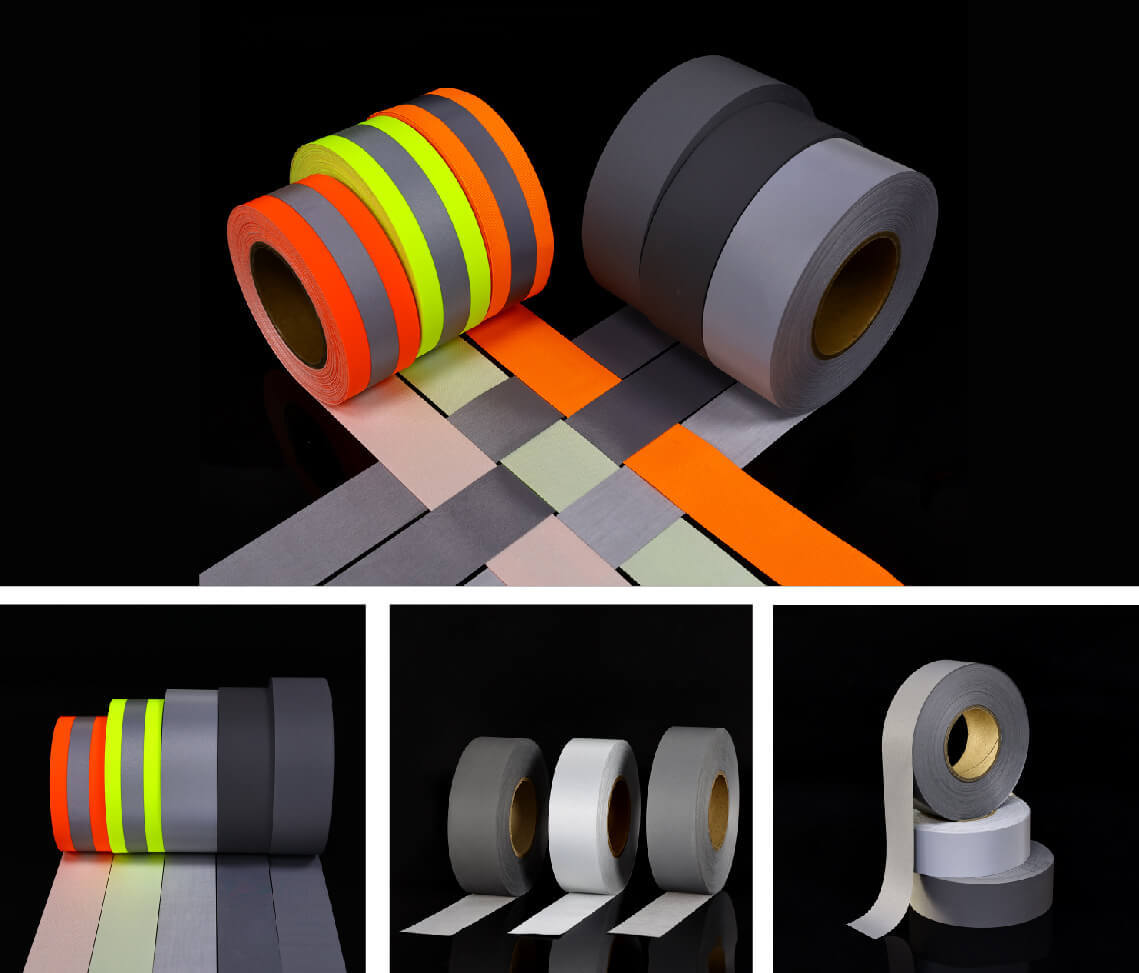

- Luminous film for reflective clothing

Focusing on flexibility and comfort, it is suitable for work clothes, police uniforms and outdoor sportswear to ensure visibility of personnel at night or in low light environments.

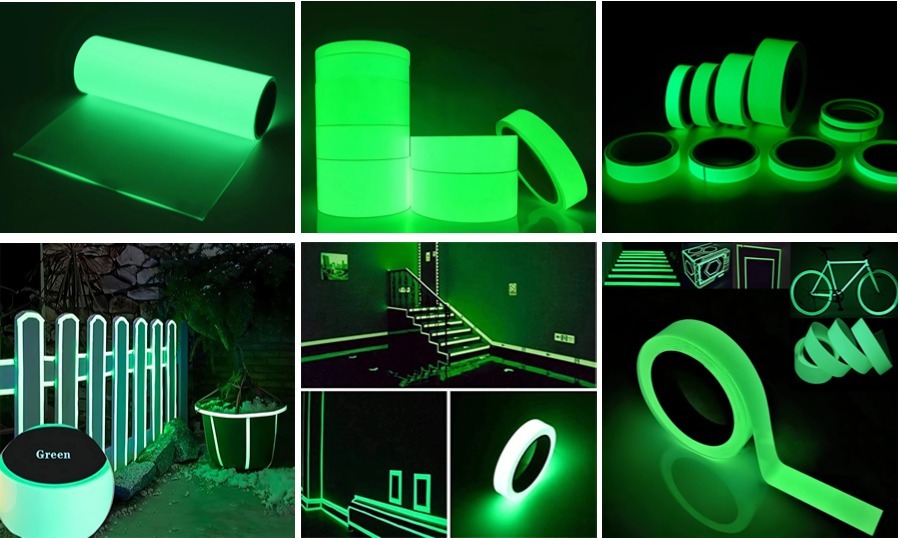

- Luminous film for traffic and safety signs

Mainly used for road signs, emergency exit signs and safety isolation belts, it requires high strength, weather resistance and long-term luminous effect.

- Luminous film for industrial applications

For industrial plants, storage areas and other environments, in addition to the night indication function, it is also required to have chemical corrosion resistance and impact resistance.

The process and production process of luminous film

The production of luminous film involves multiple high-precision process links to ensure that the product has ideal luminous effect and performance.

- Raw material selection and ratio

The luminous materials (such as rare earth luminous powder, fluorescent pigment) used in different luminous films need to be accurately proportioned, and at the same time, they are matched with high-quality substrates (such as polyester film or PVC) to ensure overall stability and environmental protection performance.

- Coating process

Adopting advanced coating technology, by evenly coating the luminous material and protective layer, the luminous film can evenly emit light after absorbing light energy, while improving its weather resistance and wear resistance.

- Printing and cutting process

For customized needs, such as special logos or pattern designs, fine printing technology is used, and the dimensional accuracy and appearance quality are guaranteed by automatic cutting equipment.

- Quality inspection and packaging

Each batch of products undergoes strict performance tests such as luminous brightness, durability, and anti-aging, and finally adopts moisture-proof and dust-proof packaging to ensure that it is not damaged during transportation and storage.

Features and advantages of luminous film

- Excellent luminous performance

- The luminous film can continue to emit light in a dark environment, ensuring visibility at a long distance. Different types of luminous films have different luminous effects and time after absorbing light energy. Users can choose the most suitable product according to actual needs.

- Weather resistance and anti-aging

High-quality luminous film can adapt to various outdoor environments, whether in extremely cold or high temperature, dry or humid environments, and can maintain stable performance.

- Environmental protection and energy saving

No power dependence, green and environmental protection

Through natural light or ambient light excitation, it reduces dependence on external power supply, and has a long service life, which is in line with the current development trend of green environmental protection.

- Safety and reliability

Quick response, long-lasting luminescence

It can play a role quickly in an emergency, helping personnel to quickly identify safe passages or dangerous areas and improve accident prevention capabilities.

Guide to selecting luminous films in different use environments

Choosing a suitable luminous film requires combining the use environment and specific needs. The following are selection suggestions for several common environments:

- Outdoor environment

Requirement characteristics: UV resistance, high temperature resistance, and wind and rain resistance.

Recommended type: Polyester-based self-luminous or photoluminescent luminous film, with excellent weather resistance and long-lasting luminous effect.

- Industrial environment

Requirement characteristics: chemical corrosion resistance, wear resistance, and impact resistance.

Recommended type: PVC/PET-based luminous film, especially suitable for chemical plants, warehouses and other places with high requirements for corrosion resistance.

- Traffic safety and emergency rescue

Requirement characteristics: high brightness, long afterglow, and rapid response.

Recommended types: fluorescent coating type and photoluminescent luminous film, which can quickly absorb and release light energy in low-light environments to ensure safety guidance in emergency situations.

- Reflective clothing and personal protection

Requirement characteristics: flexible, light, and ergonomic.

Recommended type: Luminous film for reflective clothing, mostly using self-luminous or fluorescent coating technology, which ensures safety without affecting the comfort of clothing.

Maintenance and care of luminous film

In order to ensure the luminous effect and long life of the luminous film in actual use, daily maintenance and care are very important:

- Regular cleaning

Recommended method: Use a neutral detergent and a soft cloth to wipe gently, and avoid using highly corrosive detergents to avoid damaging the surface coating of the luminous film.

Precautions: Remove dust and dirt regularly to ensure that the luminous film can fully absorb light energy.

- Avoid physical damage

Storage and use: Try to avoid scratches, collisions or heavy pressure, especially in high-intensity use scenarios such as traffic signs, and check for damage regularly.

- Prevent long-term strong direct light

Light management: The luminous film will glow after absorbing light energy, but long-term exposure to strong light may cause light attenuation. It is recommended to avoid continuous long-term direct exposure.

Storage and service life of luminous film

- Storage requirements

Ambient temperature and humidity: It is recommended to store in a dry, cool environment, avoid high temperature and high humidity, to prevent the material from getting damp, deforming or aging.

Packaging seal: Unused luminous film should be kept sealed in the original packaging to prevent dust and pollution from entering and extend the shelf life of the product.

- Service life

Under normal circumstances: High-quality luminous film can usually have a service life of more than 5 years under appropriate storage and maintenance conditions, and some high-end products even have a longer life.

Methods to extend the service life: Reasonable selection of suitable product types, regular cleaning and maintenance, and attention to environmental protection can effectively extend the service life of luminous film.

As an important material for improving night safety, luminous film has different types, processes, characteristics, and use and maintenance methods. Through the detailed analysis of this article, we hope that industry safety personnel and reflective clothing material buyers can have a more comprehensive understanding of the various application scenarios and purchase and maintenance skills of luminous films, so as to choose the most suitable products for enterprises or projects. YSM reflective material manufacturers have always been committed to technological innovation and quality assurance. We welcome customers to consult for more product information and jointly promote the development of safety protection.

If you need to learn more about product details or customization needs, please feel free to contact our professional team. We will wholeheartedly provide you with the best service and technical support.

Related News

How Long Can the Luminous Pigment Powder Glow? How Does It Glow?

2025-04-29

Why Fabrics Are Crucial to Reflective Tape for Clothing Performance

2025-04-25

Reflective Tape for Clothing: The Night Guardian of Safety Workers

2025-04-22