Luminous Film Customization and Cutting Pattern Process

2025-03-15

Ysmlite

ysmlite.com

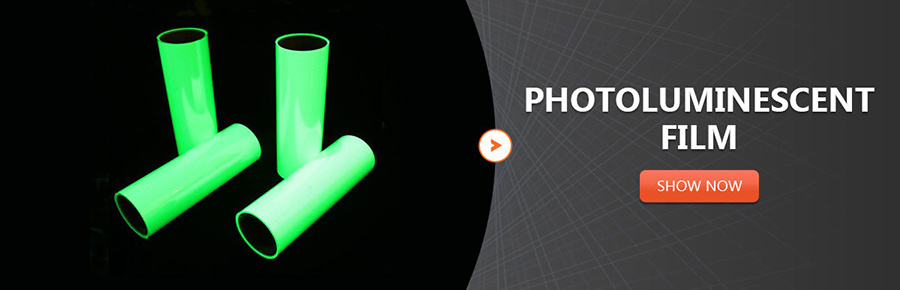

In the field of safety protection and reflective clothing, luminous film has become an indispensable key material due to its excellent self-luminous and reflective properties. With the continuous improvement of safety standards and personalized needs in various industries, the luminous film customization and cutting pattern process is ushering in technological innovation and application upgrades.

Advantages and characteristics of luminous film

The core advantages of luminous film

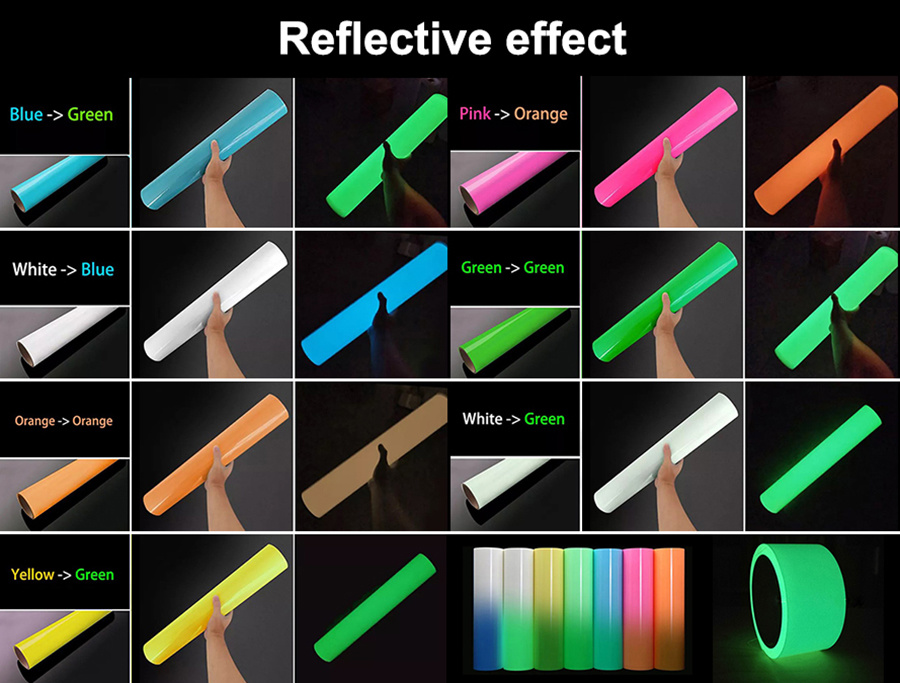

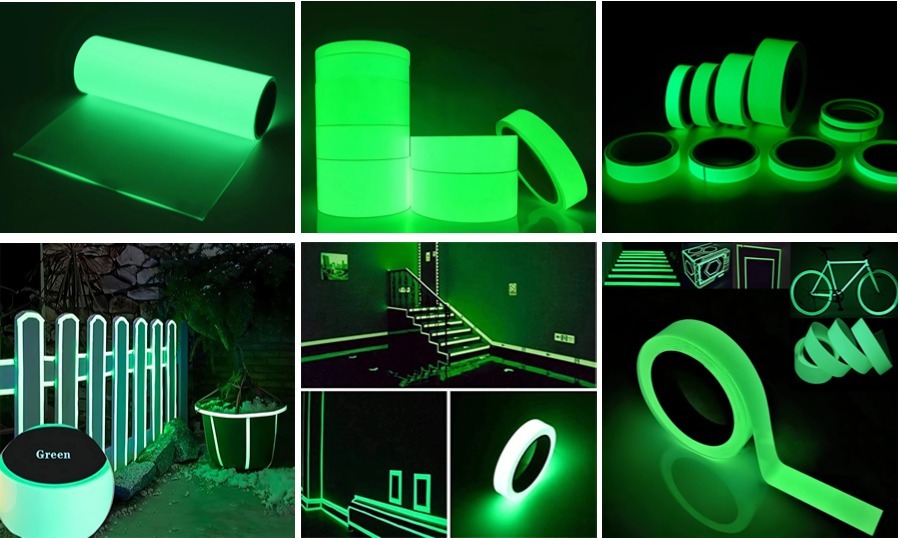

- High reflectivity and self-luminous performance: Luminous film can achieve long-term self-luminescence in low-light or no-light environments, significantly improving visibility and safety.

- Weather resistance and wear resistance: It has the characteristics of UV resistance, high temperature resistance, and low temperature resistance, ensuring that it will not deform or fade in a variety of harsh environments for long-term use.

- Environmental protection and stability: It is made of environmentally friendly raw materials, meets international green environmental protection standards, and meets the safety certification requirements of various countries.

Application scenarios

- Traffic safety: It is used in road traffic signs, warning signs and road isolation facilities to ensure night driving safety.

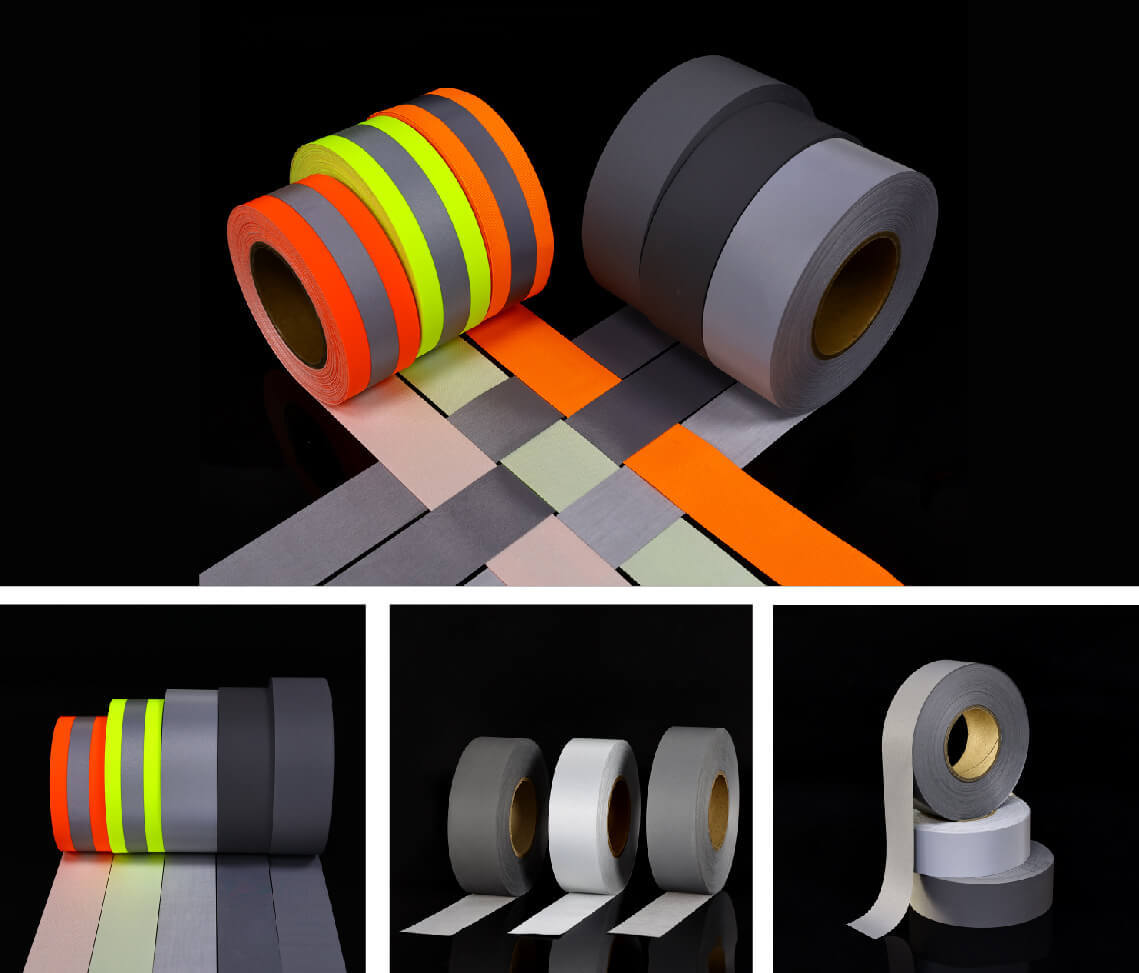

- Reflective clothing: Customized on reflective vests, life jackets, and construction site work clothes to improve the recognition of workers or rescuers in low-light environments.

- Industry and construction: suitable for high-risk construction sites, warehouse safety signs and various emergency rescue equipment.

Advantages of customized luminous film

Material performance guarantee

YSM glow in the dark vinyl adopts Class 2 reflective coefficient (≥500cd/lx/m²), supporting:

- Weather resistance: stable in -30℃ to 70℃ environment, anti-UV aging for more than 5 years (ASTM G154 test).

- Substrate compatibility: suitable for PVC, PET, TPU and other substrates, thickness 0.2mm-1.5mm optional.

Laser cutting precision control

- ±0.1mm tolerance: ensure smooth edges of complex patterns to avoid burrs affecting bonding strength.

- Intelligent path optimization: AI typesetting system reduces material loss and the maximum utilization rate reaches 95%.

Pattern design specifications

- Minimum line width 1mm: clear presentation of fine-line text and icons.

- Support vector files (AI/EPS/PDF): seamless connection with customer design teams.

Dual needs of personalization and functionality

- Brand recognition and corporate culture: Customized patterns can be integrated with corporate LOGO, iconic graphics, slogans and other elements, which not only ensures visual unity, but also highlights the company's unique brand culture.

- Scene feature matching: Design targeted patterns based on the use environment (such as transportation, industry, rescue, etc.) to maximize night recognition and warning effects.

Digital design and virtual simulation

- Professional design software: Use CAD, CorelDRAW, Adobe Illustrator and other software to achieve refined pattern design;

- Virtual preview system: Through 3D simulation and digital models, customers can preview the actual application effect of luminous film in a virtual environment and make modification suggestions in time;

- Data interaction and customized collaboration: Digital management of design solutions to achieve a closed-loop process of design, review and confirmation to ensure seamless connection of all links.

Luminous film material characteristics and process optimization

Material composition and physical properties

- Photoluminescence principle: Luminous film usually adds rare earth luminescent agents (such as zinc sulfide doped with copper, manganese, etc.), which can store energy and slowly release light energy after sufficient light source irradiation;

- Matching of adhesive and substrate: Select a substrate suitable for laser or CNC cutting process to ensure that the material does not tear or deform during the cutting process;

- Chemical resistance and anti-aging: Especially suitable for outdoor and industrial environments, to ensure the stability of product performance in long-term use.

Process improvement and technological innovation

- Comprehensive application of laser and CNC cutting: Laser cutting is suitable for processing complex and detailed patterns, while CNC cutting ensures high consistency in mass production;

- Cutting parameter optimization: Through simulation and experiment, the laser power, cutting speed and focus position are accurately adjusted to achieve the best cutting edge quality;

- Die-cutting technology innovation: In the customization of simple or repetitive patterns, the use of digital die-cutting technology can greatly improve production efficiency and reduce production costs.

Customization of the entire process

Preliminary communication and demand research

- In-depth interviews with customers on customer needs: Conduct multiple technical communications with customers to clarify pattern details, size requirements, use environment and functional indicators;

- Technical feasibility assessment: Conduct technical assessments based on demand, determine design solutions and production processes, and predict possible technical difficulties.

Digital pattern production and correction

- Design draft drawing: Senior designers produce preliminary design drafts based on customer needs to ensure that graphics, lines and colors meet safety standards;

- Digital processing and fine adjustment: Use vector graphics processing software for fine design, while performing edge details and pattern repeatability tests;

- Sample preview and feedback: Generate digital samples for customer preview, use virtual reality technology to simulate actual application effects, and ensure that the final design meets expectations.

Precision cutting and production implementation

- Laser cutting process: High-power laser equipment achieves high-speed and precision cutting, suitable for complex curves and subtle pattern processing;

- CNC cutting process: Relying on high-precision CNC equipment, achieve consistency and high precision of each piece of luminous film in mass production;

- Intelligent production line: Introduce intelligent equipment such as automatic feeding, online detection, and data feedback to ensure that the production process is highly automated and stable.

Full-process quality monitoring and testing

- Raw material testing: Strict testing of luminous film raw materials before production, including key indicators such as brightness test, reflectivity, and weather resistance;

- Intermediate process monitoring: The automatic detection system is used to monitor the cutting edge, cutting depth and accuracy in real time to ensure flawless product output;

- Finished product factory inspection: Each batch of products undergoes a strict quality inspection procedure, including reflective performance, color consistency, pattern accuracy, etc., to ensure that international safety standards are met.

Process and technology

Precise cutting of complex patterns

- Algorithm optimization and simulation technology: Advanced algorithms are used to optimize pattern segmentation to ensure that complex patterns avoid overlap and breakage during the cutting process;

- Equipment calibration and real-time monitoring: Laser equipment and CNC equipment need to be calibrated regularly, and the cutting error is fine-tuned through a real-time feedback system to ensure high-precision production.

Challenges of material and process compatibility

- Cooperative cutting of heterogeneous materials: Some customized requirements may involve multiple layers of materials or combinations of different materials, and it is necessary to develop adaptive cutting technology to avoid friction and deformation between materials;

- Environmental protection and sustainability: While ensuring performance, develop low-pollution and low-energy production processes that meet international environmental standards and green production concepts.

Market trends and future prospects

Technology integration and intelligent manufacturing

- With the continuous development of artificial intelligence, big data and Internet of Things technologies, the customized cutting process of luminous film will move towards intelligence and full automation. In the future, the equipment will achieve self-diagnosis and automatic parameter adjustment to further improve production efficiency and product consistency.

Environmental protection and new material research and development

- Under the global trend of green environmental protection, the development of low-pollution and recyclable new luminous film materials has become the focus of the industry. At the same time, the introduction of nanotechnology and new luminous materials will bring higher brightness, longer luminous time and more stable performance to the luminous film.

Cross-border integration and personalized customization

- The continuous segmentation of customized needs has prompted companies to continue to innovate in product design. Cross-border fusion design (such as integrating smart sensors with luminous films) will become an important development direction in the future, providing more added value for safety protection products and further meeting personalized market needs.

Why choose YSM luminous film customization service?

As the industry's leading luminous film manufacturing and customization expert, YSM has the following core competitive advantages:

Deep technical accumulation

- With a professional design team and senior engineers, continuous investment in research and development and process improvement to ensure that products are always in the leading position in the industry in terms of complex pattern customization and high-precision cutting.

Advanced equipment and automated production lines

- Introducing world-class laser, CNC and die-cutting equipment, combined with intelligent monitoring systems, to achieve full-process digitalization and automated production, ensuring that every process is accurate and correct.

Strict quality management system

- From raw material procurement, process control to finished product testing, a comprehensive quality monitoring system has been established. All products have passed international safety standard certification, truly achieving both safety and beauty.

All-round customized solutions

- We tailor pattern design solutions according to the actual needs of customers, provide one-stop services from preliminary communication, digital preview to mass production, and provide perfect after-sales technical support to help customers achieve brand upgrades and market competitive advantages.

The customized cutting pattern process of luminous film is not only a high-precision manufacturing technology, but also an important innovative application in the field of safety protection. Through the full process control from design concept, material characteristics, process optimization to strict quality management, YSM provides customers with a complete set of professional and customized solutions to effectively meet the needs of various safety fields such as transportation, industry, and rescue for high-standard and personalized products.

Whether you are an industry safety personnel, a purchaser of reflective clothing materials, or an enterprise focusing on high-quality customized services, YSM will provide you with luminous film products that are both safe and beautiful with advanced technology, strict quality and comprehensive customized solutions. Welcome to contact us to learn more about the product information and explore new possibilities for future safety protection together!

Related News

How Long Can the Luminous Pigment Powder Glow? How Does It Glow?

2025-04-29

Why Fabrics Are Crucial to Reflective Tape for Clothing Performance

2025-04-25

Reflective Tape for Clothing: The Night Guardian of Safety Workers

2025-04-22