How to Store Luminous Film Correctly

2025-03-18

Ysmlite

ysmlite.com

| Table of contents |

| 1. Introduction to luminous film 2. How to store luminous film correctly 3. Precautions during storage 4. Common problems and solutions 5. Storage life of luminous film |

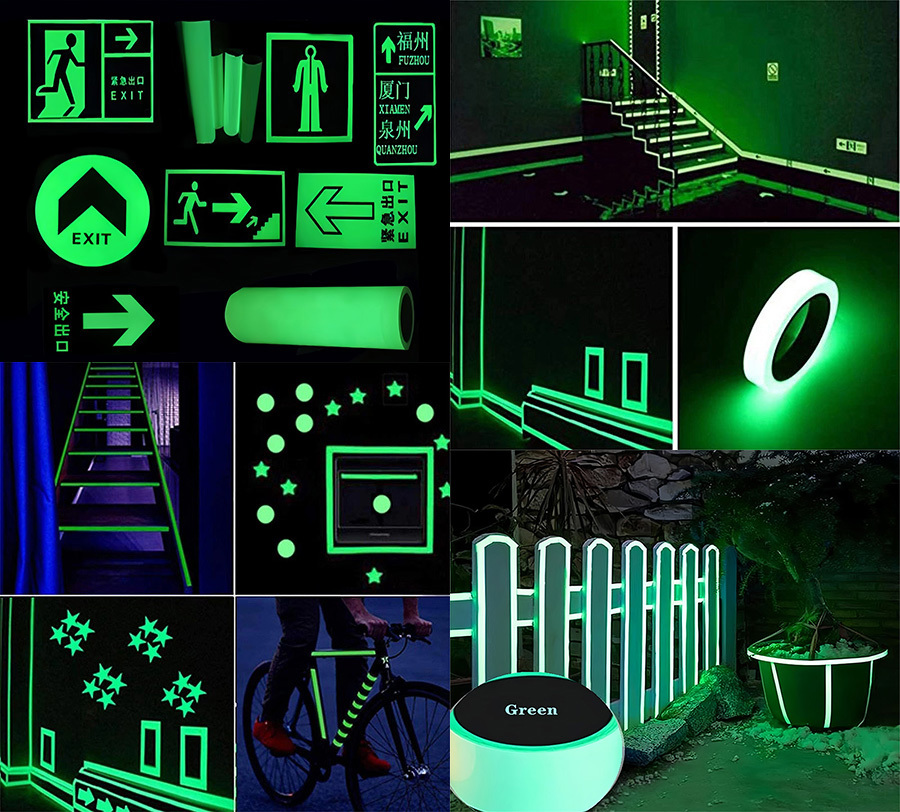

As a new high-tech material, luminous film is widely used in advertising, signage, emergency lighting and other fields. In order to ensure the luminous performance and appearance quality of the luminous film during use, the correct storage method is particularly critical.

Introduction to luminous film

Photoluminescent film is a functional material that can spontaneously glow in a dark environment. Its core lies in the photoluminescent pigment contained in it. Since the luminous performance and stability of the luminous film are closely related to the storage environment, special attention should be paid to the influence of temperature, humidity, light and chemical substances during storage. Only under the premise of strictly controlling the storage conditions can the product achieve the best effect when used.

How to store luminous film correctly

Storage environment requirements

- Temperature control:

Luminous film is sensitive to temperature. The ideal storage temperature is generally controlled between 5℃ and 25℃. Too high or too low temperature may cause the performance of photoluminescent pigments to decline or age. In particular, long-term exposure to high temperature may accelerate the chemical reaction of the pigment and reduce the luminous effect.

- Humidity management:

It is more appropriate to keep the relative humidity between 50% and 70%. Too high humidity can cause the packaging material to get damp, and even cause mold growth. At the same time, it may cause water droplets or pollution on the film surface, thus affecting the light effect; while too low humidity may cause static electricity to accumulate and increase the risk of dust adsorption.

- Storage away from light:

Although the luminous film needs to work in a dark environment, it should avoid long-term direct exposure to strong light (especially ultraviolet light) during the storage stage. Long-term ultraviolet radiation will not only consume the luminous pigment prematurely, but also cause the film surface to age and discolor.

- Ventilation conditions:

Good ventilation helps to keep the storage environment fresh and dry. Harmful gases or volatile organic compounds may gather in a confined space, which is not conducive to the chemical stability of the luminous film. Therefore, it is recommended to choose a warehouse or storage room with better ventilation conditions.

Packaging and stacking methods

- Original factory packaging is the main method:

Luminous film is usually packaged in anti-static, moisture-proof and dust-proof professional packaging when it leaves the factory. It is recommended to keep the original packaging as intact as possible during storage. If secondary packaging is required, protective materials with similar properties to the original packaging materials should be selected.

- Flat storage:

The material of the luminous film is relatively soft and prone to bending, creases or wrinkles. It should be kept as flat as possible during storage to avoid uneven pressure when stacked. It is best to use a hard support board to fix it.

- Avoid heavy pressure:

Try to avoid stacking heavy objects on the luminous film to prevent mechanical pressure from causing local deformation or damage to the internal photosensitive materials.

- Clear labeling:

Each batch of luminous film should be carefully labeled before storage, including production date, batch, storage period and other information, so as to facilitate regular inspection and first-in-first-out management to ensure that the quality of inventory products is always in the best condition.

Precautions during storage

Environmental monitoring and regular inspection

- Temperature and humidity monitoring:

It is recommended to install temperature and humidity monitoring equipment in the storage place to record environmental data in real time. Once abnormal environmental parameters are found, measures should be taken in time to adjust or change the storage place.

- Check the packaging status regularly:

Check the packaging regularly to prevent external contamination due to packaging damage. During the inspection, pay attention to observe whether there is moisture, mildew, mechanical damage, etc.

Prevent cross contamination

- Isolate storage:

Luminous film should be stored separately from chemicals that are volatile, corrosive, or easy to release harmful gases. Even in the same warehouse, isolation measures should be taken to avoid cross contamination affecting product performance.

- Keep clean:

The storage environment should be kept clean and tidy, and cleaned regularly to prevent dust and dirt from accumulating. This not only helps to extend the service life of the luminous film, but also avoids the reduction of light efficiency due to dust accumulation.

Anti-static measures

- Anti-static packaging:

Luminous film is easily affected by static electricity, which may absorb dust or cause minor surface damage. It is necessary to use anti-static packaging materials or set up static elimination equipment in the storage area.

- Pay attention to protection during operation:

When handling and handling luminous film, staff should wear anti-static clothing and gloves to avoid direct contact with the product surface and reduce static interference and pollution.

Common Problems and Solutions

Luminous Performance Attenuation

- Problem Description:

After long-term storage, the luminous intensity of some luminous films may decrease.

- Possible Causes:

Ambient temperature is too high or too low, resulting in abnormal chemical reactions.

Long-term exposure to light (especially ultraviolet rays) causes the luminous pigment to decay prematurely.

Water vapor generated in a high humidity environment affects the structure of the pigment.

- Solution:

Strictly store in accordance with the recommended temperature, humidity and light-proof conditions; regularly monitor storage environment data; rotate inventory when necessary to ensure first-in, first-out.

Wrinkled or damaged film surface

- Problem Description:

During stacking and storage, some luminous films may be wrinkled due to heavy pressure or bending, affecting the appearance and use effect.

- Possible Causes:

Not kept flat during storage.

Stacking too high causes excessive local pressure.

- Solution:

Use a flat and sturdy support plate to assist storage; avoid stacking too high; regularly check inventory products and adjust the stacking method in time.

Surface contamination or watermarks

- Problem description:

Some luminous films may have surface watermarks or stains in a humid or polluted environment, affecting transparency and luminous effects.

- Possible causes:

The packaging is damp in a high humidity environment.

Dust or pollutants enter the packaging in the storage environment.

- Solution:

Keep the storage environment dry and clean; choose packaging with good sealing; if problems are found, clean it in time and perform appropriate repairs according to the product instructions.

Storage life of luminous film

Normal shelf life range

Under ideal storage conditions (temperature, humidity, light avoidance, and ventilation meet the requirements), the shelf life of glow in the dark film can generally reach 3 to 5 years. The specific shelf life will be affected by the product formula, manufacturing process and storage environment.

Environmental impact on shelf life

- Temperature and humidity:

If the ambient temperature continues to deviate from the standard range, it will accelerate the aging of the photoluminescent pigment in the luminous film; excessive humidity may cause the packaging to become damp, indirectly affecting product quality.

- Lighting conditions:

Even if the luminous film works in the dark, if it is often exposed to strong light or ultraviolet light during storage, its luminous ability may be consumed in advance and the shelf life may be shortened.

- Mechanical damage:

Improper long-term stacking or handling may cause physical damage to the film surface and affect the long-term stability of the product.

Suggestions for extending the shelf life

- Optimize the storage environment:

Choose a storage place with stable temperature, humidity and good lighting conditions, and conduct regular monitoring and adjustment.

- Regular inspection and maintenance:

Establish a strict inventory management system, regularly inspect products and packaging, and promptly detect and deal with abnormal situations.

- Scientifically rotate inventory:

Follow the first-in-first-out principle to prevent long-term storage from causing product performance degradation. If necessary, some products can be preventively tested to ensure that their luminous performance is not affected.

As a functional material with high requirements for the storage environment, the correct storage method can not only ensure its excellent luminous effect, but also extend the service life of the product. In general, the ideal storage method should focus on the following points:

- Choose a suitable storage environment to keep the temperature, humidity, light protection and ventilation conditions stable;

- Use original protective packaging and ensure that the product remains flat and pressure-free during stacking;

- Check inventory regularly to prevent cross-contamination, static electricity accumulation and packaging damage;

- Follow a scientific inventory management system to ensure that the product is put into use in the best condition.

By implementing the above storage measures, both companies and customers can effectively reduce the quality problems caused by improper storage of luminous film and ensure that the product has the greatest light effect and safety in actual applications.

Related News

How Long Can the Luminous Pigment Powder Glow? How Does It Glow?

2025-04-29

Why Fabrics Are Crucial to Reflective Tape for Clothing Performance

2025-04-25

Reflective Tape for Clothing: The Night Guardian of Safety Workers

2025-04-22