Standards and Requirements For Fire Retardant Reflective Tape

2025-03-12

Ysmlite

ysmlite.com

In the field of global safety protection, flame retardant reflective tape is not only an important auxiliary component to improve visibility, but also a key technical component in protective equipment. As countries continue to improve their safety standards, flame retardant reflective tape must meet strict standards in terms of material composition, process processing and performance testing.

Analysis of technical standards and requirements in various regions around the world

North American market: strict flame retardant and safety testing

- UL 94 test standard

In North America, UL 94 is the main standard for evaluating the combustion performance of materials. Flame retardant reflective tape must reach V-0, V-1 or even V-2 levels, among which V-0 requires the material to have the highest requirements in flame extinguishing time and the amount of dripping combustion products to ensure that it can quickly extinguish itself once it encounters fire. During product testing, the laboratory will use standard flame contact test instruments to record the burning time, extinguishing rate and melting droplets to verify its flame retardant performance.

- NFPA series standards

For fire and industrial safety clothing, in addition to UL testing, it must also comply with standards such as NFPA 2112 and NFPA 70E, focusing on the performance of materials under long-term high temperature and flame exposure. These tests usually involve comprehensive performance of heat resistance, chemical corrosion resistance and mechanical wear resistance.

European market: multi-level safety and environmental standards

- CE certification and EN standards

The European market requires products to obtain CE certification, indicating that the products meet basic requirements such as health, safety, and environmental protection. Flame-retardant reflective tapes in Europe need to meet the EN 13501-1 fire classification standard, which ranges from A1 (non-flammable) to F (flammable). In addition, for the reflective performance of traffic and safety clothing, it is also necessary to follow EN ISO 20471 or EN 471 standards, which specify parameters such as reflectivity, viewing angle range, and weather resistance in detail.

- Environmental protection and chemical safety requirements

The European market has strict restrictions on chemical residues and volatile organic compounds (VOCs), requiring that products must control the release of harmful substances during production and use to ensure that they are harmless to the environment and human body. Manufacturers usually need to obtain RoHS and REACH certification to prove that the material composition is safe.

Asian market: Diversified standards and detailed management

- Chinese standards (GB/T series)

In China, flame-retardant reflective tapes must comply with relevant test standards such as GB/T 19156, covering flame retardancy, heat resistance and durability. Test methods include pyrolysis temperature, flame propagation speed and smoke density tests to ensure that the product can provide sufficient self-protection time in the event of a fire.

- Japanese and Korean standards

Both Japan (JIS) and South Korea (KS) have unique requirements for flame-retardant products, not only focusing on flame spread, but also emphasizing the stability of materials in extreme temperature and high humidity environments. Especially in the Japanese market, the test items will also involve aging resistance after long-term ultraviolet exposure to ensure that the product is still reliable in outdoor or high-intensity use environments.

Detailed technical requirements for flame-retardant reflective tapes in different industries

Clothing industry: the perfect combination of safety and comfort

- Integrated flame-retardant and reflective design

In safety clothing, protective clothing and work clothes, fire retardant reflective tape must not only meet the specified flame barrier standards, but also maintain a stable reflective effect under multiple washing, friction and high temperature environments. Technical requirements include:- Washability test: After more than 30 standard washes, the reflectivity and flame retardant properties of the tape shall not decrease by more than 10%.

- Flexibility and adhesion: The material should be flexible enough to adapt to the bending of clothing, while maintaining long-term adhesion on the clothing fabric to prevent degumming due to wearing and pulling.

- Comfort and breathability

For clothing with high requirements for wearing comfort, the tape material must take into account the breathability design, and achieve a balance between flame retardant protection and comfortable experience through microporous technology or film technology.

Industrial safety and firefighting equipment: multiple performance guarantees

- High mechanical strength and chemical corrosion resistance

In the field of industrial production and firefighting equipment, products are often faced with mechanical friction, chemical solvent erosion and high temperature tests. Flame-retardant reflective tapes must pass stretching, peeling and weathering tests:- Tensile and tear resistance: ensure that the tape does not lose its protective properties due to structural fatigue under stress.

- Chemical resistance: After acid, alkali and solvent tests, it is ensured to remain stable in chemically corrosive environments.

- Extreme environmental adaptability

In addition, it is crucial for the product to maintain its performance in extreme environments such as high temperature, low temperature, humidity and ultraviolet radiation. Professional testing equipment simulates various extreme climatic conditions to detect the physical and chemical stability of flame-retardant layers and reflective materials.

Transportation and public safety: high visibility and long-term durability

- Ultra-high reflective efficiency

The reflective performance of flame-retardant reflective tapes used for traffic safety, road signs and public facilities is measured by standardized instruments. Common indicators include brightness (expressed in candela per square meter) and viewing angle range. Product design must ensure that it can still provide clear reflective warnings in low-visibility environments such as dim light, rain and snow.

- Weather-resistant and wear-resistant design

Products in the transportation field must cope with long-term exposure to the sun and rain, drastic temperature differences and frequent physical wear. Materials need to use special coating treatments and polymer synthesis technology to extend product life and maintain stable flame-retardant reflective effects.

Detailed maintenance and care guide for flame retardant reflective tape clothing

To ensure that the flame-retardant reflective tape embedded in the clothing always maintains excellent performance, the following detailed measures are recommended:

Cleaning and disinfection

- Low-temperature washing strategy

Avoid high-temperature water washing. It is recommended to use warm water below 30°C and neutral detergent for washing. Use a gentle washing mode to prevent high-speed rotation from causing mechanical damage to the tape.

- Chemical selection

It is strictly forbidden to use detergents containing bleach, strong alkali or strong acid, which may damage the flame-retardant layer and reflective coating of the tape. It is recommended to use washing products specifically for protective clothing to maintain material performance.

Storage and daily care

- Anti-UV storage

Flame-retardant reflective tape clothing should be stored in a cool, dry and light-proof environment. Prolonged exposure to strong ultraviolet rays may cause material aging and performance degradation. It is recommended to use anti-UV bags or shade cloth for storage.

- Regular inspection and performance testing

Check the tape regularly (such as every 3-6 months) for abnormal phenomena such as degumming, cracking, color fading, etc. For frequently used safety clothing, it is recommended to send it to a professional testing agency for flame retardant and reflective performance testing regularly to ensure that it meets the standard requirements.

Precautions for use environment

- Avoid severe friction

In high-friction environments, minimize direct contact with rough surfaces. You can protect the tape surface by adding a protective layer to the outer layer of the clothing or using additional fixing tapes.

- Avoid long-term exposure to chemical environments

If there are high concentrations of chemicals or corrosive gases in the workplace, it is recommended to take additional protective measures or replace specially designed chemical-resistant products.

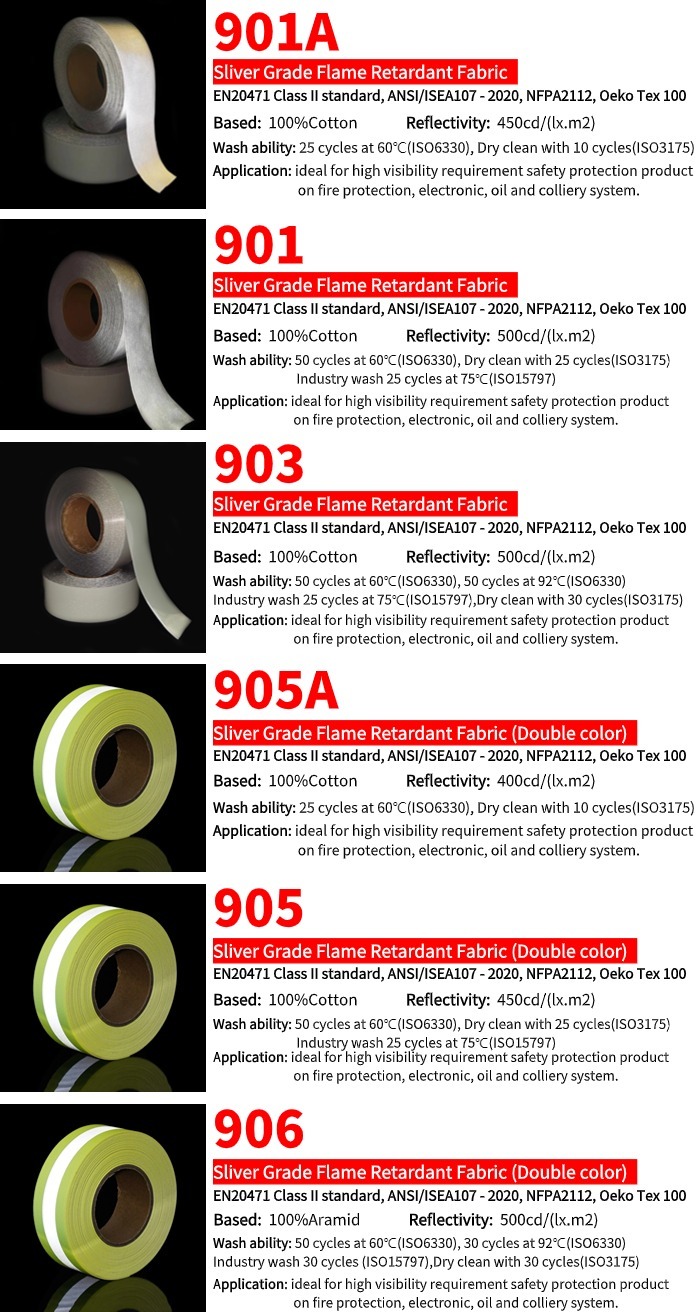

International certification and technical advantages of Ysmlite flame retardant reflective tape

Ysmlite always takes customer safety and product quality as the core. It not only adopts advanced technology in the R&D and manufacturing process, but also passes strict international certification to ensure that the product can play the best performance in various regions and application fields:

- Multiple international certifications

- The product has passed the North American UL test, European CE and EN series standard test, and complies with the Chinese GB, Korean KS and Japanese JIS standards to ensure the highest safety performance in different markets and application scenarios.

- Passed ISO9001 quality management system certification, each batch of products undergoes strict quality inspection and environmental simulation tests to ensure long-term stability and safety.

- Leading materials and processes

- Using polymer modification technology and nano-level flame retardant additives to optimize the molecular structure of the material, fundamentally improve the fire resistance, wear resistance and chemical corrosion resistance.

- Precision production technology and strict factory management ensure that the product still performs well in multiple mechanical stretching, temperature cycles and chemical environments.

- Customized solutions

- Ysmlite provides customized flame-retardant reflective tape solutions for different industry customer needs, whether it is high-frequency washing, extreme climate environment or high-intensity mechanical application, it can provide the best solution.

- Continuous technological innovation and R&D investment enable continuous product iteration and upgrading, ensuring that each batch of products can meet or exceed the most stringent international safety standards.

In today's increasingly stringent safety protection and industrial standards, firefighter reflective tape is an important safety protection component, and its technical requirements cover material flame retardancy, reflective performance, mechanical durability and environmental adaptability. With leading material technology, strict quality control and multiple international certifications, Ysmlite is committed to providing global customers with safe and efficient flame-retardant reflective tape solutions, helping various industries to improve safety protection standards and product competitiveness.

Through continuous technological innovation and strict standard implementation, Ysmlite is winning market reputation with professionalism and integrity, and becoming the preferred safety protection brand in various industries. Whether in daily working environment or under extreme safety requirements, Ysmlite can provide customers with all-round, customized high-quality products and services to jointly build a safer future.

Related News

How Long Can the Luminous Pigment Powder Glow? How Does It Glow?

2025-04-29

Why Fabrics Are Crucial to Reflective Tape for Clothing Performance

2025-04-25

Reflective Tape for Clothing: The Night Guardian of Safety Workers

2025-04-22