YSM: Top Luminous Film Factory Manufacturer in China

2025-07-10

Ysmlite

ysmlite.com

What is luminous film? ——Understand the working principle and basic knowledge of luminous film

Photoluminescent film, also known as self-luminous film, is a material that can continuously emit light in a dark environment. It is widely used in safety warnings, traffic signs, decorative signs, cultural and creative products and other fields. Its core principle is "energy storage-energy release": when there is light, the luminous powder in the film absorbs visible light energy (such as sunlight or light) and stores it; once it enters a dark environment, this energy will be released in the form of visible light, forming a continuous luminous effect.

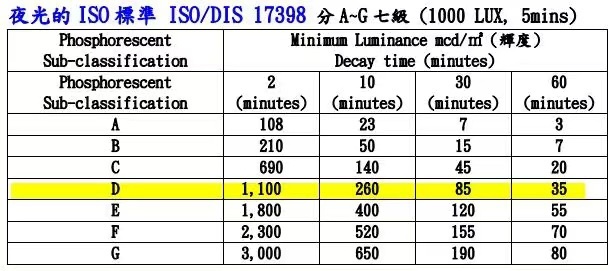

Luminous film usually consists of three parts: substrate (such as PVC, PET, acrylic, etc.), luminous coating (mainly containing rare earth long afterglow luminous powder) and protective film. The particle size, content and distribution uniformity of the luminous powder directly determine the brightness and duration of the luminous film. According to the brightness level and luminous duration, the luminous film can be divided into high brightness type, medium brightness type and economic type to meet the needs of different scenarios.

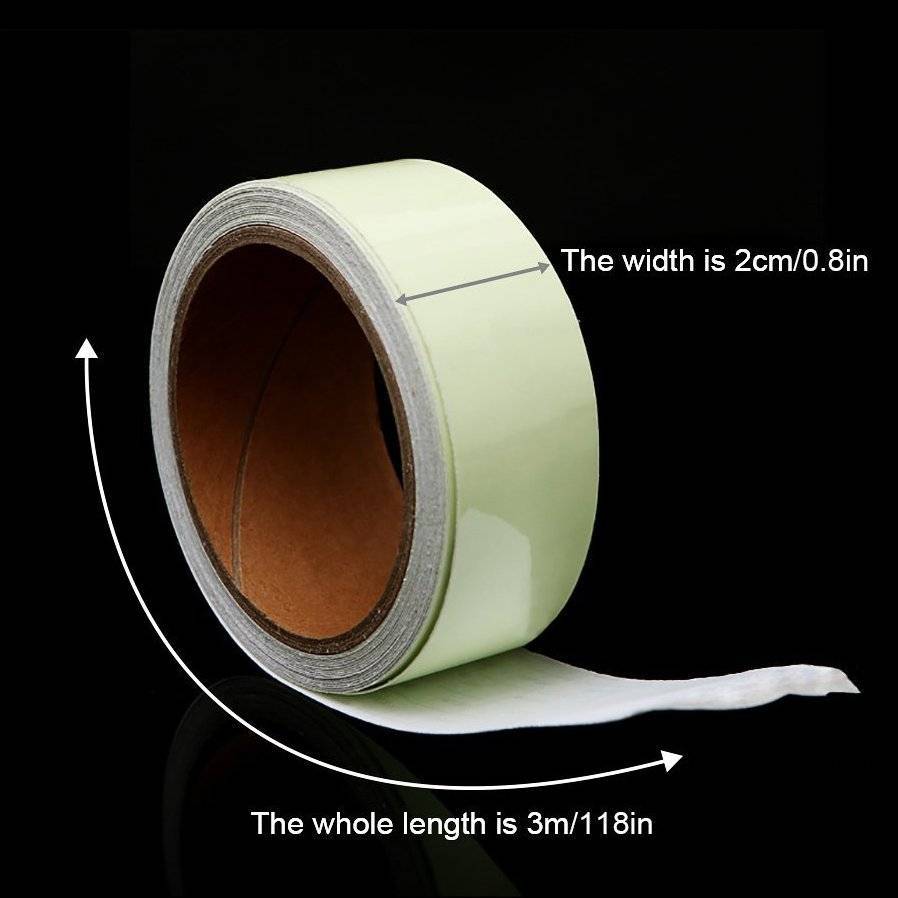

In addition, the luminous film can be made into self-adhesive and non-self-adhesive types. The self-adhesive type has adhesive on the back, which can be pasted after being torn off, and is easy to use; the non-self-adhesive type is suitable for hot pressing, silk screen printing or other post-processing forms. YSM has the ability to produce a variety of luminous films, and can choose the most suitable material and structure according to customer needs.

Advantages of YSM luminous film: innovative formula, precise process, and complete certification

As a benchmark enterprise in China's luminous film manufacturing, YSM has long been focused on the research and development and production of luminous materials. The reason why its products stand out in the domestic and foreign markets is mainly due to the following advantages:

Self-developed formula and luminous powder selection

YSM insists on using high-purity rare earth luminous materials, and has developed the best ratio of luminous powder through its own laboratory, which can effectively improve the luminous intensity and duration. The self-developed coating formula makes the luminous layer more uniform, avoids spots and dark areas, and improves the overall aesthetics and practicality.

Precision coating and laminating process

The company has introduced multiple high-speed fully automatic coating lines with a maximum width of 1.3 meters and an error control within ±0.05mm. After coating, precision lamination and defoaming technology are used to ensure that the surface of the luminous film is smooth, free of bubbles and peeling, and is suitable for various secondary processing such as die-cutting, printing, stamping, etc.

Diverse materials and rich structures

YSM can supply luminous films with various substrates such as PVC, PET, acrylic, etc., which can meet the application requirements of different customers. For example, PVC is suitable for conventional indoor and outdoor signs, while PET is suitable for long-term outdoor use and has better weather resistance.

Environmental protection and complete certification

YSM luminous film products have passed multiple international certifications such as REACH, RoHS, EN71, SGS, etc., ensuring that they are harmless to the human body, environmentally friendly and recyclable, and are particularly suitable for project requirements exported to European and American countries.

How to choose a luminous film product that suits your needs? ——Practical purchasing tips

When purchasing luminous film, the most critical parameters include luminous brightness, duration, substrate type, thickness, adhesive performance and processing adaptability. Here are some practical suggestions to help you find the right product quickly:

Clearly define the usage scenario and functional positioning

If it is used for safety evacuation signs, it is recommended to use a PET-based luminous film with high brightness and long afterglow, which has strong adhesion, good waterproof and temperature resistance; for wall stickers, you can choose a self-adhesive PVC film, which is easy to operate and moderately priced.

Check the brightness and afterglow time

The luminous films provided by YSM are divided into high brightness (initial brightness can reach 300mcd/m²), medium brightness (150~200mcd/m²) and other grades. For environments that require long-term lighting, products with an afterglow time of more than 6 hours should be selected.

Adhesive type selection

YSM can provide three types of adhesive-free, ordinary pressure-sensitive adhesive and strong adhesive. If it is used for short-term construction, ordinary adhesive can be selected; for long-term outdoor signs, strong adhesive type should be selected.

Sample testing cannot be ignored

It is recommended to request samples before purchasing large quantities of products to test their performance in actual light and dark environments, including adhesion, cutting effect, residual adhesive, etc. YSM supports free standard sample books and customized samples to facilitate customers to compare and choose.

The strength of YSM luminous film factory is revealed: the whole process from raw materials to shipment

YSM has more than 25 years of experience in manufacturing luminous materials, covers an area of more than 10,000 square meters, and has a complete integrated production process:

Raw material procurement and quality inspection: Cooperate with many rare earth suppliers at home and abroad, all luminous powders have passed heavy metal and radioactive element detection, and meet international environmental standards.

Automated coating and lamination: Adopt the coating system imported from Germany, operate in a constant temperature and humidity environment to ensure the stability of the luminous layer.

Fine cutting and laminating packaging: Cut the size according to customer needs, and cooperate with the laminating unit to increase the surface wear resistance.

Comprehensive quality inspection system: Each batch of products must undergo light-dark box comparison test, stretch test, temperature and humidity resistance test to ensure that the factory qualified rate exceeds 98%.

Fast delivery capability: Regular models are fully stocked, and customized orders can be shipped in as fast as 3 days. YSM supports OEM/ODM services and has established long-term cooperation with customers in Europe, America, Japan, and Southeast Asia.

Suggestions for the use and maintenance of luminous films (practical tips)

In order to maximize the use effect and life of luminous films, the following are some practical tips recommended by YSM:

- Avoid high temperature or strong acid environment: Luminous materials are sensitive to high temperature and acidic substances, and should be stored away from heaters and chemical raw materials.

- Clean the pasting surface before use: Dust and oil on the surface will seriously affect the adhesion, and it needs to be cleaned with alcohol or detergent before applying the film.

- Compact and remove bubbles after applying the film: Use a scraper to remove bubbles from the center to the surroundings to avoid residual air causing warping.

- Avoid long-term direct sunlight: Although the PET substrate has a certain degree of weather resistance, long-term strong light exposure will still accelerate aging. It is recommended to avoid exposure to extreme climates.

Why choose YSM as your luminous film supplier? ——Real customer case analysis

Among many successful cooperation cases, a German emergency sign equipment company has cooperated with YSM to customize a high-brightness luminous film for emergency evacuation passages in subway stations. The project requires that the product still has a clear and visible guiding effect within 10 minutes after a power outage. YSM ensures that its brightness is stable above 200mcd/m² by adjusting the formula and the distribution of luminous powder. It received high praise from customers during project acceptance and has maintained a cooperative relationship for three consecutive years.

Another Southeast Asian children's product brand customer encountered the problem of luminous film peeling during product testing. The YSM technical team assisted in analyzing the substrate tension problem and customized fine-tuning the formula, which not only solved the degumming problem, but also improved the printing adaptability, and finally successfully passed the European and American toy safety standard test.

Luminous film may seem simple, but the material ratio, manufacturing process, viscose processing, environmental certification and other links behind it cannot be ignored. Choosing a professional luminous film manufacturer is equivalent to providing a solid guarantee for product quality and project stability. As China's leading luminous film factory, YSM not only has strong R&D and manufacturing capabilities, but also demonstrates high maturity and flexibility in service system, delivery control, and customized response.

Whether you are purchasing high-performance glow in the dark film for engineering projects or developing creative products that require luminous materials in a variety of colors and forms, YSM can provide you with a trustworthy solution. Welcome to contact YSM for samples and quotations, and let the luminous light illuminate your brand.

Related News

YSM: Top Luminous Film Factory Manufacturer in China

2025-07-10

Top 5 Fire Retardant Reflective Tape Manufacturers in Europe

2025-07-07

YSM Leading Photoluminescent Film Manufacturer Factory

2025-07-03