YSM Leading Photoluminescent Film Manufacturer Factory

2025-07-03

Ysmlite

ysmlite.com

In the dark, we instinctively look for light sources, and luminous film is a material that can glow for a long time in an environment without electricity, protecting our life, work and safety. It is widely used in safety signs, clothing accessories, children's toys, emergency exit signs and other fields, and is an important branch of modern functional materials. With people's attention to nighttime visibility and safety, the luminous film market is growing steadily. However, the quality of luminous films on the market varies. How to choose a truly professional and trustworthy luminous film manufacturer has become the focus of many buyers and brand customers.

As a professional reflective materials manufacturer with many years of deep cultivation in the field of reflective and luminous materials, YSM has not only accumulated profound technical experience in material research and development, but also set an industry benchmark in product quality control, customer customization services, and international certification.

Introduction to YSM Luminous Film

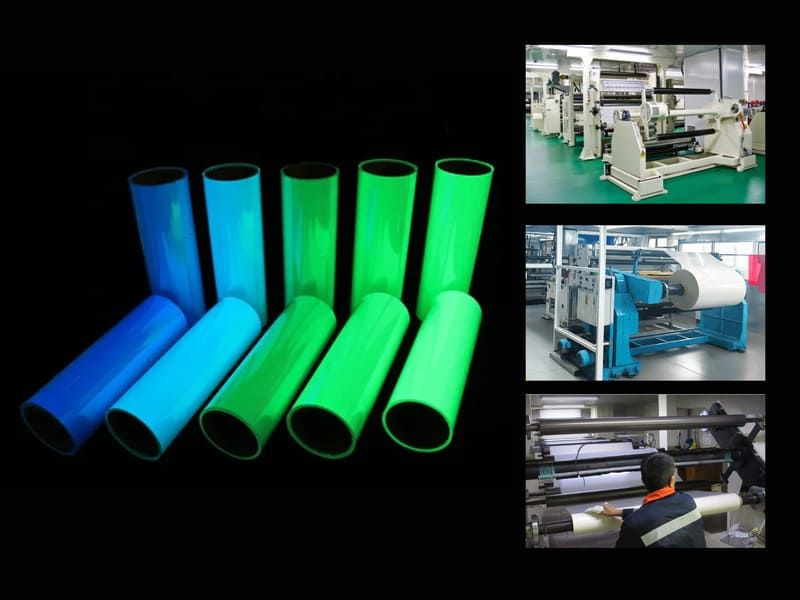

Luminous film, also known as self-luminous film, mainly relies on the principle of photo-storage luminescent materials, that is, absorbing energy when there is sufficient light and continuously releasing visible light in the dark. YSM luminous film uses high-purity rare earth long afterglow luminescent powder as the core luminous component, supplemented by polymer substrates (such as PVC, PET, TPU, acrylic, etc.) for coating and lamination to form a composite film material with excellent light storage performance and physical stability.

YSM follows the four principles of "high light absorption efficiency, long afterglow time, good material flexibility, and wide adaptability" in formula design, so that its luminous film can store energy within 3-5 minutes under natural light, and can continue to glow for more than 8 hours in the dark. It can withstand changes in different temperature and humidity environments, and is not easy to age or powder. The products are widely used in various personalized customization, industrial-grade signs, disaster prevention and mitigation, safety tips, entertainment products and other fields.

YSM's technical advantages: leading the industry in every step from raw materials to film formation

YSM's ability to establish a leading position in the field of photoluminescent films stems from its comprehensive and systematic technical capabilities. From the selection of basic raw materials to the final product delivery, YSM adheres to the following key technical advantages:

Precise control of the ratio of luminous materials: YSM uses its own formula to synthesize luminous powder, which has uniform particle size, high purity, and stronger light absorption and luminous efficiency. Its exclusive technology can control the luminous wavelength and afterglow duration, and improve the brightness and durability of the luminous film.

Uniform coating technology: The company has multiple automated high-precision coating lines, which can accurately control the coating thickness and the distribution density of luminous materials to ensure the consistency of brightness and thickness of large-scale products.

High adhesion substrate treatment: Through special corona treatment and interfacial active modification technology, the luminous layer is more firmly combined with the substrate, and it can maintain excellent performance even in repeated bending, washing, friction and other environments.

Weather-resistant and anti-aging design: YSM luminous film is optimized with light stabilizers and antioxidants, and can be used stably for more than 2 years in outdoor strong ultraviolet and humid environments without fading or cracking.

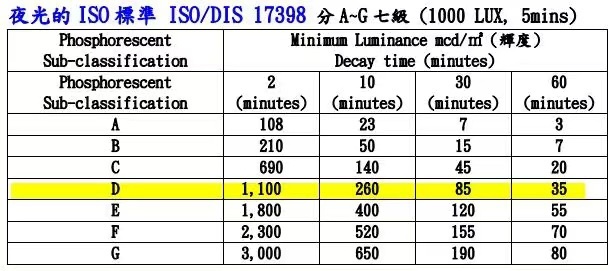

International standard testing: All products have passed strict RoHS, REACH, EN71 and other certifications, and have been tested by independent optical laboratories for multiple dimensions such as brightness, afterglow decay curve, color difference, and temperature resistance. The data is authentic and traceable.

Detailed explanation of various types of luminous films and application scenarios

YSM is well aware that different customer groups have different needs for luminous films, so it has created a rich and diverse product series to meet various application needs from industrial signs to personal creative DIY.

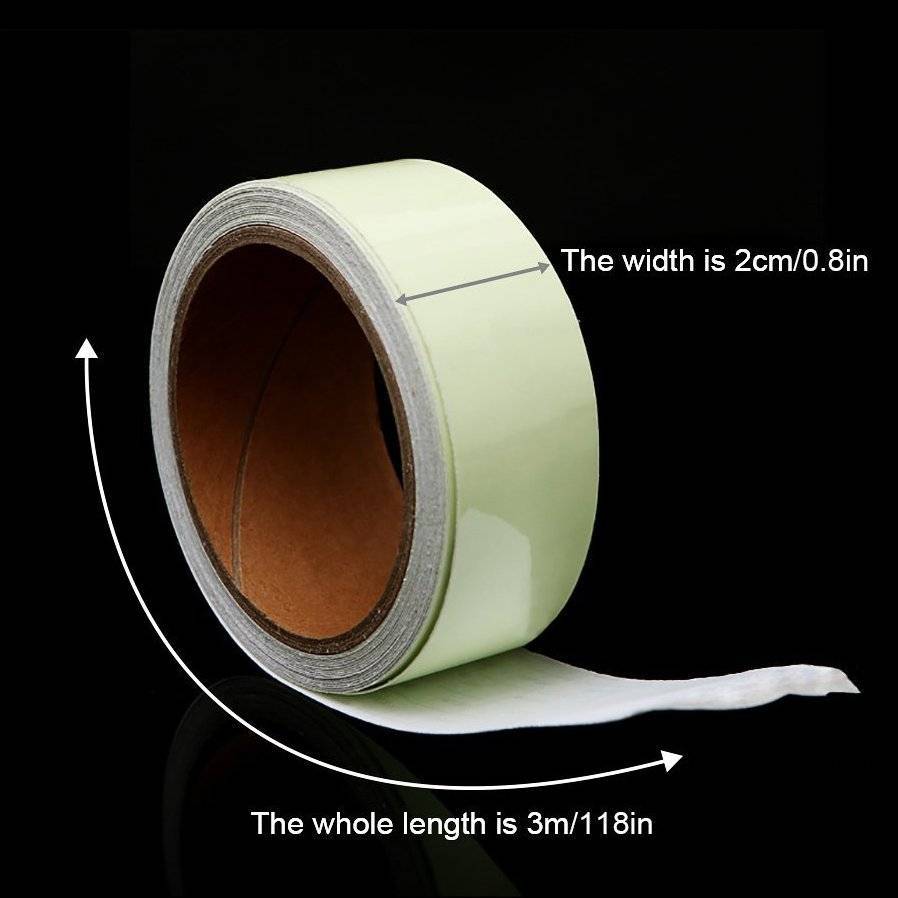

- PVC luminous film: soft and easy to stick, suitable for flat safety signs, floor stickers, wall stickers, etc., often used in public places such as subways, shopping malls, and hospitals.

- PET luminous film: The surface is smoother and more heat-resistant. It is suitable for laser cutting and high-precision printing processes. It is the preferred material for industrial labels and equipment indicator stickers.

- Transparent luminous film: translucent or colorless during the day, luminous at night, suitable for applications with high aesthetic requirements such as glass, lampshades, and window stickers.

- Printable luminous film: compatible with UV, screen, thermal transfer and other printing methods, widely used in personalized products such as luminous clothing, luminous advertisements, luminous toys, etc.

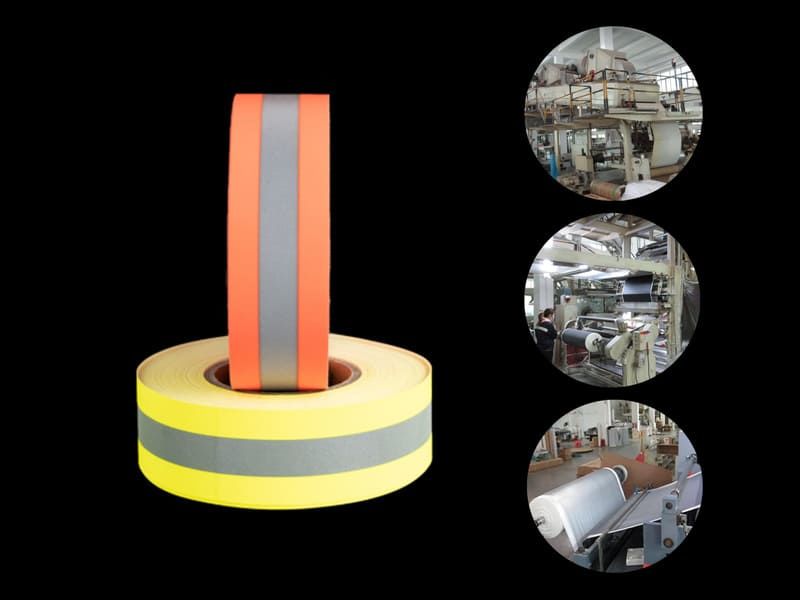

- Waterproof luminous film: using waterproof substrate and encapsulation layer, suitable for outdoor guidance signs, bicycle decals, night running equipment and other occasions with high frequency contact with water sources.

Through technology empowerment, YSM luminous film not only has good physical properties, but also has strong functional adaptability, and is widely trusted by customers around the world.

YSM manufacturing process revealed: professional process and efficient quality control

YSM adheres to the quality concept of "every batch is like a sample" and implements strict process control during the manufacturing process. The specific process is as follows:

- Raw material inspection: each batch of luminous powder, solvent, resin, substrate, etc. must pass 10+ test indicators such as color difference, purity, moisture, etc. to ensure that the source is controllable.

- Homogeneous dispersion: high-speed shear stirring technology is used to evenly disperse the luminous powder in the resin solution to avoid agglomeration affecting the uniformity of luminescence.

- High-precision coating: Multi-roll coating is carried out in a constant temperature and dust-free environment. The coating thickness accuracy can be controlled within the range of ±2μm to ensure consistent brightness.

- Drying and curing: The film material is dried and shaped through a segmented constant temperature drying tunnel to adjust the optimal state of the luminous powder to make the afterglow time longer.

- Slitting and laminating: Automatic slitting and protective film lamination are carried out according to customer requirements to avoid scratches and contamination during transportation and processing.

- Full inspection and packaging: Each roll of product must be double-tested by manual and machine before leaving the factory, and the batch number and luminous parameters must be marked to ensure traceability and consistency.

Controlling quality from every link, YSM always adheres to the manufacturing attitude of "high standards and zero tolerance", which is also the fundamental reason why its luminous film products have been selling well in the European, American and Japanese markets for a long time.

Customized luminous film solution: How to choose the right product according to your needs

Different scenarios have different requirements for the brightness, thickness, softness, environmental protection level, etc. of luminous films. YSM provides a complete customized solution. The process is as follows:

- Requirement confirmation: Communicate with customers through sales engineers to confirm the application direction (apparel, logos, toys, etc.), use environment (indoor and outdoor, humid, high temperature, etc.), luminous color, brightness requirements, etc.

- Sample development: Proofing according to customer needs, providing thickness, material, adhesive type, luminous time comparison test samples.

- Mass production and packaging: After confirming that the sample is correct, quickly organize production, and perform slitting, packaging, label design, etc. according to customer requirements.

- After-sales support: YSM provides technical support manuals to assist customers in film process improvement, printing compatibility testing and application optimization.

For example: A European and American children's clothing brand hopes to develop a children's backpack sticker that can flash at night. YSM develops a flexible PET substrate and uses yellow-green luminous powder to ensure that it is compatible with the hot pressing process while ensuring the safety of children, achieving the unity of product beauty and function.

Environmental protection and certification guarantee: How does YSM achieve green production and docking with international standards?

YSM adheres to the concept of environmentally friendly production, and all luminous film products meet the international mainstream environmental standards, including:

- RoHS certification: prohibits the use of harmful heavy metals such as lead, cadmium, and mercury.

- REACH certification: in line with the EU's high control of chemical safety.

- OEKO-TEX® Standard 100: suitable for clothing and personal care products to ensure that the material is non-irritating to the skin.

- EN71-3 Toy Safety Certification: can be used for children's toys and accessories, does not contain migratable toxic elements.

In addition, YSM has developed its own low-VOC water-based resin coating solution to reduce the harmful gas emissions of traditional solvent-based luminous films during the production process, and built a wastewater recycling system to achieve more than 95% recycling.

Customer Cases and Successful Applications: How Global Brands Choose YSM Cooperation

German Subway Signage Company: YSM's high-brightness luminous PVC film is selected for rail emergency exit signs. The product has passed the DIN67510 standard test and the luminous duration exceeds 12 hours.

American children's product brand: customized environmentally friendly luminous PET film for luminous puzzle toys, which meets the EN71-3 standard and has a 20% sales increase after successful listing.

Japanese sports equipment manufacturer: Use YSM luminous film to develop reflective tape for night running, improve night visibility, and is well received by users.

These successful cases prove that YSM not only has manufacturing capabilities, but also has the strength to provide high-quality solutions to global customers.

How to choose a high-quality luminous film supplier: practical suggestions and evaluation tips

To choose a trustworthy luminous film factory, it is recommended to evaluate from the following aspects:

- Does the product have a third-party authoritative certification?

- Can customized services be provided? Is the response timely?

- Is the manufacturing process transparent? Can proofing and process suggestions be provided?

- Does it have professional after-sales support?

- Is the customer case real? Is it a long-term and stable cooperation?

YSM performs well in all the above indicators, especially in terms of response speed and technical support, which is widely praised by customers.

In the pursuit of safer, more beautiful and more environmentally friendly luminous solutions today, YSM provides stable and reliable luminous film products to global customers with rich industry experience, mature manufacturing technology and sincere service attitude. Whether you are a brand, trader or terminal processing plant, as long as you have a need for luminous film, YSM can provide you with a solution that exceeds your expectations. Let YSM's luminous film add a touch of safe light to the night, and let trust and professionalism illuminate every cooperation.

Related News

Application of Flame Retardant Reflective Tape in Electrical Engineering

2025-08-15

Exploring Ysmlite luminous Film Factory: Focused on Quality

2025-08-15

Ysmlite’s Factory Advantages as Fireman Reflective Tape Manufacturer

2025-08-13