Opening Up New Realm of Luminous Film Research and Development

2025-03-25

Ysmlite

ysmlite.com

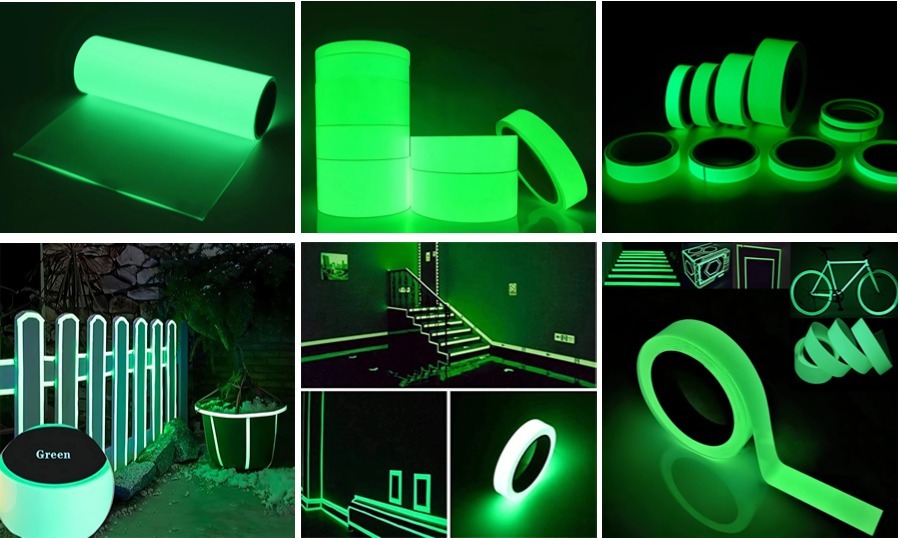

In the current high-end lighting and decorative materials market, luminous film is gradually becoming the darling of major companies and brands due to its excellent self-luminous properties and wide application scenarios. As an excellent enterprise, how to achieve high quality and high cost performance of luminous film products through cutting-edge technology research and development, strict control of raw materials, precision production technology, perfect quality system and customer customization solutions in the fierce market competition is the goal pursued by every luminous film factory.

Cutting-edge research and development and technological breakthroughs

Technology accumulation and R&D platform construction

The research and development of high-quality luminous film starts with a solid technical platform. Enterprises need to form interdisciplinary and multi-field R&D teams covering professional fields such as material chemistry, optical engineering, surface physics and environmental engineering. By introducing advanced domestic and foreign instruments and equipment (such as spectrometers, microscopes and environmental test chambers), a standardized R&D laboratory is established to provide scientific basis and data support for product development.

In-depth analysis of the principle of optical luminescence

The core of luminous film lies in its luminous performance. Modern luminous film mainly relies on rare earth elements (such as europium, cerium, neodymium, etc.) or new inorganic phosphorescent materials for light energy absorption and conversion. Enterprises should conduct in-depth research on the energy level transition mechanism, photon absorption and re-emission efficiency of these luminescent materials, and explore the influence of doping ratio, particle size distribution and microstructure on luminous performance. At the same time, combined with computer simulation technology, optimize the hierarchical structure of composite materials to improve brightness and continuous luminous time.

Innovative materials and composite processes

In material research and development, although traditional organic dyes are widely used, they have problems such as short life and insufficient weather resistance. By introducing new inorganic phosphorescent materials or combining organic materials with nanocomposites, the luminous stability and environmental aging resistance of luminous films can be significantly improved. In addition, studying the influence of different substrates on light efficiency transmission and developing multi-layer composite structures will help solve technical problems such as light scattering and reduced transmittance.

Strict screening and quality control of raw materials

Raw material purity and environmental standards

High-quality luminous film is inseparable from the high purity of raw materials. Enterprises must control from the source to ensure that all luminous powders, resins, adhesives and additives meet international or industry standards. By establishing long-term and stable cooperative relationships with high-quality suppliers, a raw material traceability management system is implemented to prevent the mixing of impurities and pollutants. At the same time, pay attention to environmental protection indicators, select low-toxic, harmless and degradable materials, and ensure environmental safety during production and use.

Batch consistency of raw materials

During the production process, the consistency between batches of materials directly affects the stability of the product. Enterprises should introduce advanced raw material testing equipment, conduct component analysis and performance testing on each batch, and ensure that all indicators (such as particle distribution, chemical stability, thermal stability, etc.) meet the design requirements. By establishing a complete supply chain management system, the quality fluctuations of raw materials can be monitored in real time to reduce product performance deviations caused by raw material differences.

Innovative production process and intelligent manufacturing

Automated production line and process control

In the production process, the use of automated and intelligent production equipment is an important means to ensure product consistency. Automated coating machines, precise temperature control drying systems and high-precision cutting equipment are used to achieve standardized control of luminous film thickness, coating uniformity and edge processing. By introducing PLC systems and industrial Internet of Things, real-time monitoring and data collection are carried out for each process, and automatic adjustment and optimization of process parameters are achieved, thereby reducing production errors and defective rates.

Multi-layer composite and new process exploration

In order to improve the overall performance of luminous films, enterprises can develop multi-layer composite processes. The multiple structures of pre-coating, functional layer and protective layer can not only improve the luminous brightness, but also enhance the product's anti-friction, waterproof and weather resistance. For example, adding a layer of high-transmittance protective film to the outside of the luminous layer can effectively isolate ultraviolet radiation and mechanical wear. In addition, the exploration of new processes also includes low-temperature curing, rapid drying technology and green solvent-free coating technology, which can reduce energy consumption and environmental pollution while ensuring product performance.

Full-process quality monitoring and standardized certification

Full-process quality inspection system

From the entry of raw materials into the factory, production and processing to the delivery of finished products, strict quality monitoring is required in every link. By establishing a full-process quality inspection system, each batch of products is tested for spectrum, weather resistance, adhesion and scratch resistance. Enterprises can introduce statistical process control (SPC) and Six Sigma management methods to monitor and analyze data in real time, promptly discover and solve potential problems in the production process, and ensure that each piece of luminous film meets the design indicators.

International and industry standard certification

Passing international certifications such as ISO, CE, and RoHS proves that the product not only meets high standards in performance, but also meets environmental protection and safety requirements. Enterprises should continuously improve their internal quality management systems and regularly invite third-party testing agencies to conduct evaluations and audits to maintain the competitiveness of product quality worldwide. At the same time, according to industry development trends, the testing standards and methods are constantly updated to enable enterprises to always maintain a leading position in technology in a changing market environment.

Customer customization and market precision positioning

In-depth research and customized design

High-quality luminous films should meet the special needs of different industries and customers. Enterprises should understand customers' specific requirements in terms of brightness, color, durability, size, etc. through market research, customer interviews and demand analysis, and design corresponding products for different scenarios (such as indoor and outdoor signs, billboards, decorative materials, etc.). Customized design not only increases the added value of products, but also enables enterprises to have competitive advantages in diversified markets.

Technical service and after-sales support

Excellent enterprises not only pursue excellence in product research and development and production, but also pay attention to long-term cooperation with customers. Establish a professional technical service team to provide customers with product selection suggestions, installation and commissioning guidance, and subsequent maintenance services. By setting up customer feedback channels and after-sales service centers, timely solve problems that arise during use, incorporate customer opinions into the next product improvement, and form a virtuous circle.

Environmental safety and sustainable development strategy

Green process and energy saving and consumption reduction

In the context of increasingly stringent global environmental protection requirements, enterprises need to implement green environmental protection concepts in the research and development and production process. From material selection, process to packaging, low-energy, low-pollution and recyclable solutions must be adopted. By using solvent-free and low VOC (volatile organic compound) technology, clean production and energy conservation and emission reduction can be achieved in the production process, creating a green brand image for the company.

Waste recycling and resource recycling

A certain amount of waste will inevitably be generated during the production process, and companies should actively explore waste recycling and reuse technologies. By establishing a closed-loop recycling system, production waste, scraps and aging products are separated and processed, and reused in the production process, which not only reduces production costs, but also reduces environmental pollution, and achieves efficient recycling and sustainable development of resources.

The development of high-quality photoluminescent film is a systematic project involving various aspects such as technology research and development, material selection, production process, quality inspection, customer needs and environmental safety. In the process of continuous exploration and breakthroughs, excellent companies not only need to maintain a keen sense of the forefront of technology, but also need to achieve fine control and efficient operation from raw materials to products through collaborative management of the entire industrial chain. Only by continuous innovation and improvement can we occupy a leading position in the fierce market competition, provide customers with more reliable and competitive luminous film products, and promote the entire industry to move towards green, intelligent and efficient directions.

Related News

How Long Can the Luminous Pigment Powder Glow? How Does It Glow?

2025-04-29

Why Fabrics Are Crucial to Reflective Tape for Clothing Performance

2025-04-25

Reflective Tape for Clothing: The Night Guardian of Safety Workers

2025-04-22