How to Prolong the Service Life of Flame Retardant Reflective Tape?

2025-05-22

Ysmlite

ysmlite.com

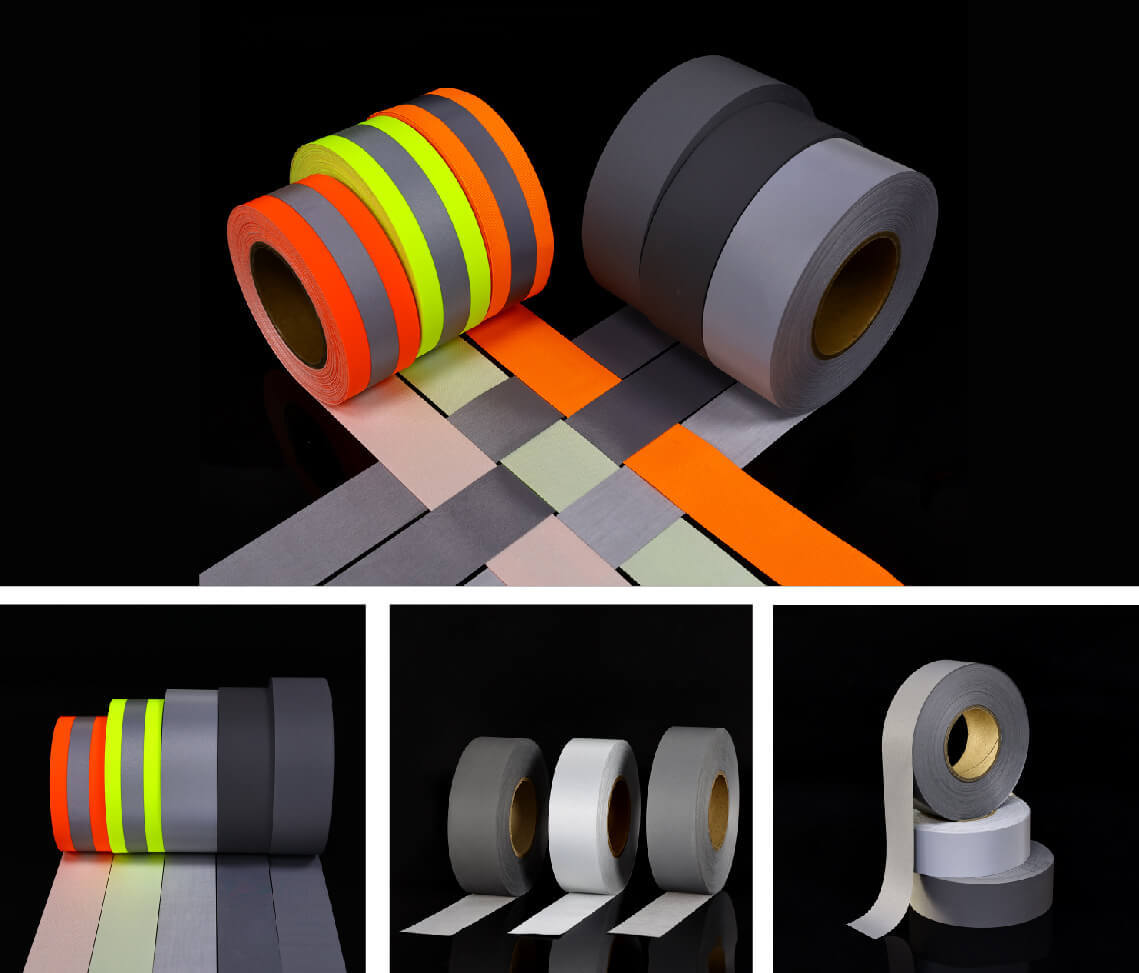

In high-risk and high-security environments, flame retardant reflective tape is not just a decorative material. It often represents whether a person can be seen in time at night and whether he can get a greater chance of survival in an emergency. These reflective materials are widely used in fire suits, railway work clothes, police uniforms, sanitation clothes and chemical protective clothing. They must still maintain the dual properties of "reflective conspicuousness" and "flame retardant protection" in extreme environments.

However, in reality, we often find that reflective tape on clothing gradually loses its reflective brightness after a period of use, and even appears edge, shedding, yellowing, and loss of flame retardant performance after washing or friction. Behind these problems, there are actually many misunderstandings in use and maintenance.

Working principle and key performance analysis of flame retardant reflective tape

To extend the service life of fire retardant reflective tape, you first need to understand its material structure and working mechanism.

Flame retardant reflective tape is usually composed of three parts:

- Base material layer: flame retardant polyester, aramid or composite fabrics.

- Reflective layer: reflective effect is achieved through glass microbeads or microprism technology, attached to the adhesive layer.

- Adhesive layer: used to firmly adhere the tape to the surface of the fabric.

Reflective principle:

The current mainstream reflective principle is to use high refractive index glass beads. When external light shines on the surface of the glass beads, the light is refracted and reflected back to the direction of the light source, thereby improving the wearer's visibility in a dark environment. This principle is called "retroreflection".

Flame retardant mechanism:

Flame retardant performance comes from the flame retardant system added to the tape, such as:

- Halogen flame retardants (such as chlorinated paraffin, chlorophosphate)

- Halogen-free flame retardant system (such as nitrogen-phosphorus complex, melamine phosphate)These flame retardants release combustion-inhibiting gases or form oxygen-isolating carbon layers at high temperatures to block the spread of flames.

Key performance indicators of life:

- Reflection coefficient: usually measured in cd/lx·m², with an initial value in the range of 300~500 and a high end of 700 or more.

- Flame retardant grade: such as EN ISO 14116 (EU standard), NFPA 701 (US standard)

- Washability: Standard industrial washing generally requires no peeling after more than 50 times; home washing for more than 20 times still maintains performance.

- Peel strength: The higher the adhesion, the more resistant to friction and washing.

By understanding these principles, we can more accurately find the core links that affect the service life.

Key preparations before use: Maintenance tips during storage and transportation

Many people think that flame-retardant reflective tape only needs careful care when it is used, but this is not the case. The life of the material begins to count down from the moment it leaves the factory.

Storage condition recommendations:

- Temperature control: Keep at 15~25℃ to avoid overheating or condensation.

- Humidity control: Relative humidity is controlled at 40%~60% to avoid moisture causing viscosity reduction or material deterioration.

- Anti-ultraviolet light: UV light has a great impact on the aging of reflective adhesives, and direct sunlight exposure should be avoided.

- Stay away from corrosion sources: Do not place them in the same warehouse with strong acids, alkalis, greases, and volatile chemicals.

Packaging method recommendations:

- It is recommended to use PE bags for separate packaging + shading film + carton + wrapping film.

- All materials should be placed upright, not stacked or compressed to prevent deformation and wrinkles.

Warehouse management tips:

- Implement the first-in-first-out (FIFO) principle to avoid expired inventory.

- Set expiration dates and label identification for all batches, and check the status monthly.

Although these measures may seem like details, they can effectively avoid the embarrassment of reflective tape performance degradation before use in the long run.

Precautions during application: How to avoid common misunderstandings

The temperature, pressure, time and other controls of flame-retardant reflective tape during the application process directly affect the adhesion and lifespan. The following wrong practices deserve attention:

Correct pressing parameters are recommended:

- Temperature: 140~160℃

- Time: 10~15 seconds

- Pressure: 3~5kg/cm²

Fabric and tape adaptation:

- For cotton fabrics, more thorough heating is required.

- Polyester fabrics are prone to slippage, so the pressing pressure needs to be increased.

- It is recommended to use the matching flame-retardant tape for test pressing of aramid fabrics.

Common error cases:

- Insufficient temperature: poor adhesion and easy edge formation after washing.

- Too high temperature: damage to the reflective layer structure and loss of brightness.

- Unpreheated fabrics: The moisture in the fabric has not been completely dissipated, causing the adhesive layer to bubble.

- Wrong position: high friction area is easy to wear and the life is greatly reduced.

Recommended professional equipment:

- Digital display heat press (with temperature control function)

- Temperature test patch or infrared thermometer

- Peel strength tester, used to check the adhesion strength

Reasonable equipment and operation procedures are a key guarantee for the service life.

The impact of the use environment on the life: climate, light, friction and chemicals

The "aging speed" of flame retardant reflective adhesive is closely related to its environment, especially in high temperature, strong ultraviolet rays, and high friction usage scenarios, the deterioration will be significantly accelerated.

Climate impact:

- High humidity environment will accelerate the hydrolysis of the adhesive layer, resulting in decreased adhesion.

- High temperature breaks the molecular chain of the adhesive layer and reduces thermal stability.

Ultraviolet impact:

- According to the ASTM G154 standard, the UV aging experiment shows that after 72 hours of continuous exposure, the brightness of general reflective adhesive decreases by 20%~40%.

Friction and stretching effects:

- Reflective tape is prone to cracking and abrasion when workers frequently bend, squat, rub the ground, etc.

- Especially in high-stretch areas such as elbows, knees, shoulders and backs, it is not recommended to attach tape.

Chemical corrosion effects:

- Solvent cleaning agents, strong acids and alkalis, engine oil, etc. may damage the tape structure.

- The difference between industrial washing and home washing lies in pH control and detergent residue.

Data reference:

- Ordinary flame-retardant reflective tape can withstand 50 washings under industrial washing.

- But if the pH>10 washing liquid is encountered, the performance may drop sharply after only 20 times.

Cleaning and maintenance guide: keep the reflective effect as long as new

The maintenance and management of flame-retardant reflective tape should not wait until "problems" occur before intervention. Scientific cleaning and daily inspection can effectively improve its durability.

Correct cleaning method:

- Use neutral detergent (pH=6.5~7.5)

- Wash with warm water (recommended below 40℃)

- Wrap in a mesh bag to reduce pulling

- Do not use chlorine-containing bleach and softener

Drying suggestions:

- Do not use a high-temperature dryer, the temperature should be controlled below 50℃

- It is recommended to air dry naturally and avoid direct sunlight

Daily inspection focus:

- Whether there is edge peeling, yellowing, uneven reflection, etc.

- Whether the reflection intensity has decreased, if necessary, a reflector can be used to test

User feedback whether there is discomfort or safety hazards

Advanced methods to extend the life

In addition to use and maintenance, the choice of materials themselves and clothing design will directly affect the life of flame-retardant reflective tape.

How to choose the right tape:

- Preferably use a high wash resistance grade (such as ISO 6330 60℃ 50 times) certified products

- YSM recommends models such as the 9700-FR series, with a reflective brightness of 500+, and flame retardant standards that meet EN469

- Pay attention to whether the product supports high-frequency hot pressing laminating process

Laminating process:

- Hot pressing lamination can achieve better molecular bonding between glue and cloth than cold laminating

- Temperature control should be accurately controlled within the range of ±2℃ to avoid false laminating or carbonization

Fabric matching suggestions:

- Flame retardant cotton, aramid, etc. have flame retardant properties and are easier to combine with reflective glue

Polyester/cotton blended fabrics need to be pre-treated to enhance the fit

Clothing design pitfall avoidance guide:

- Avoid high friction areas such as crotch, waist, shoulders and back areas to paste tape

- Use cutting and segmented pasting method to avoid cracking due to stress of whole-strip pasting

- Curved corners are processed to reduce the chance of cracking

Quality control suggestions:

- Before each batch of clothing leaves the factory:

- Reflective brightness test (required ≥300 cd/lx·m²)

- Flame retardant test (compliant with EN14116 or NFPA701)

- Peel strength test (>12N/25mm)

These advanced technologies can often double the stable performance of your products.

The value of flame retardant reflective tape is not only reflected in its reflective brightness and flame retardant level, but also in whether it can "stick to the end" at the critical moment. Many people ignore the importance of life management until they find that the tape falls off, the reflective fails, and it is dangerous to wear.

I hope these contents can help you more effectively extend the service life of flame retardant reflective tape, improve the overall safety level of clothing, and maximize the value of every purchase.

In the future, if you want to purchase flame retardant reflective materials with stronger durability and more stable performance, please contact us YSM. We will provide professional product advice, test data support and technical services to help you create more reliable high-visibility safety protective clothing.

Related News

Application of Flame Retardant Reflective Tape in Firefighter Equipment

2025-07-18

Application of Glow in the Dark Film in Safety Signage

2025-07-16

Ysmlite:Luminous Film Manufacturer Providing Leading Services

2025-07-15