Why Should You Pay Attention to Heat Transfer Reflective Webbing Tape?

2025-05-26

Ysmlite

ysmlite.com

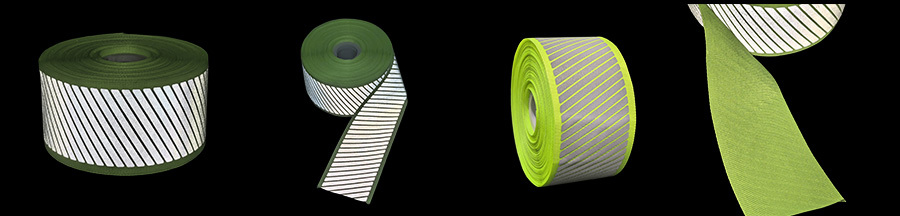

In modern clothing design and functional product manufacturing, safety and beauty are no longer an either-or choice. More and more brands and manufacturers are looking for a material that can improve the wearer's visibility while meeting the needs of design and comfort. Heat transfer reflective webbing is a solution that came into being.

With the frequent nighttime activities in cities and the increasingly stringent industrial safety regulations, people have put forward higher requirements for visual safety. Reflective materials have gradually expanded from the initial road administration signs to clothing, shoes and hats, backpacks and other fields. As a material that combines flexibility and high reflectivity, heat transfer reflective webbing is not only easy to operate, but also can achieve rich patterns and positioning printing. While improving the functionality of clothing, it also greatly expands the design space.

For reflective material manufacturers, safety equipment companies, school uniform purchasers, and designers in the field of personalized customization, a deep understanding of the characteristics and usage of heat transfer reflective webbing will undoubtedly make the product more competitive.

What is heat transfer reflective webbing?

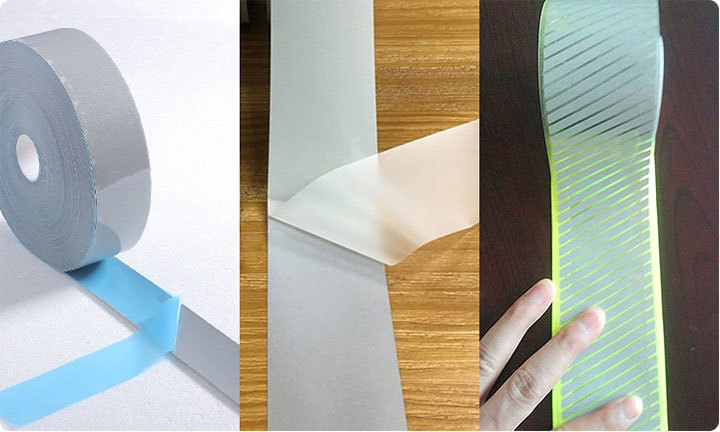

Heat transfer reflective webbing tape is a special material that transfers the reflective layer to clothing or fabric by heating. It consists of three parts:

- Reflective layer: usually composed of thousands of tiny high-refractive glass beads, which are evenly arranged and coated in a transparent adhesive layer. When light is irradiated, these beads will reflect the light back to the direction of the light source, forming a strong reflective effect.

- Base film layer: mostly made of PET or PU material, it plays a bearing role and helps the reflective layer maintain its intact structure during the heating process.

- Hot melt adhesive layer: Located at the bottom, it is the key to ensure that the reflective pattern adheres firmly to the clothing. The adhesive layer is activated by high temperature and pressure to achieve bonding.

The working principle of heat transfer reflective webbing is very intuitive: the webbing is heated to a specific temperature (generally 130℃-160℃) by a heat press and other equipment, and the hot melt adhesive is melted and combined with the fabric under pressure. After cooling, the base film is torn off to complete the transfer of the reflective pattern.

The core advantages of heat transfer reflective webbing: safety, beauty and craftsmanship

High reflectivity improves safety

The core value of heat transfer reflective webbing lies in "visible safety". Whether working at night, outdoor sports or in traffic environments, this material can quickly reflect the illumination from car lights or lights, improve the wearer's visibility, and greatly reduce the risk of accidents.

Rich patterns and high design freedom

Unlike traditional sewing reflective tape, the heat transfer process supports personalized pattern customization, and can accurately transfer complex graphics such as LOGO, barcode, wave shape, dot shape, etc. to the designated area to achieve a unique visual effect.

Soft and comfortable, does not affect the wearing experience

Traditional reflective strips tend to harden the fabric and affect comfort. The heat transfer reflective webbing is almost integrated with the fabric after the transfer is completed. It is not only soft and natural, but also has good stretch and rebound properties, which is suitable for elastic fabrics such as sportswear and tights.

Washable, dry-cleanable, not easy to fall off

High-quality heat transfer reflective webbing can withstand multiple washing and dry cleaning after professional treatment, and is even suitable for industrial washing processes. This makes it particularly suitable for work clothes, uniforms and other clothing that need to be used for a long time.

High processing efficiency, suitable for mass production

The operation process is relatively simple, only hot pressing equipment is required, no sewing is required, and the transfer efficiency is high, which is suitable for large-scale standardized operations. For manufacturers, this means shorter production cycles and less labor costs.

Main application scenarios of heat transfer reflective webbing: from work clothes to sportswear

Industrial and occupational safety clothing

In high-risk environments such as construction sites, road construction, and night shift work, reflective clothing has become a regulatory necessity. Heat transfer reflective webbing is widely used in key areas such as shoulders, backs, and trouser legs of such clothing due to its high durability and reflective brightness.

School uniforms and children's safety clothing

Many countries require children's clothing to be equipped with reflective materials in specific parts to improve visibility on the way to school. Heat transfer webbing is not only safe, environmentally friendly, and non-irritating, but can also be integrated into children's clothing design in the form of cartoons, patterns, etc., taking into account safety and beauty.

Sports and outdoor equipment

More and more sports brands are using reflective materials in products such as running clothes, cycling clothes, and mountaineering backpacks to improve users' nighttime visibility. Heat transfer reflective webbing is particularly suitable for the dynamic needs of such products because it is light, thin and soft.

Fashion trends and personalized customization

Not only functional clothing, heat transfer reflective tapes are also used in street style, stage costumes, trendy T-shirts and other fields. Its bright reflective effect and free pattern design add avant-garde visual impact to clothing.

How to use heat transfer reflective tapes correctly? Complete operation steps and detailed techniques

Although the technology of using heat transfer reflective tapes is mature, the operation process still needs to pay attention to the following details to ensure firmness and visual effects:

Prepare tools

- Heat press (it is recommended to use models with uniform temperature and timing function)

- Flatten fabrics (such as polyester, cotton, TC blends, etc.)

- Heat transfer reflective tapes (cut the pattern or length in advance)

Operation steps

- Preheat the heat press: set the temperature to 130℃160℃, and select the pressure (recommended 35kg/cm²) and pressing time (generally 10~15 seconds) according to the fabric material.

- Pre-iron fabric: The fabric can be preheated for 2-3 seconds before formal transfer to remove surface moisture and wrinkles.

- Positioning and fitting: Place the heat transfer reflective webbing as needed at the specified position of the fabric, with the pattern facing up.

- Pressing and transferring: Gently press the heat press to the set parameters to ensure uniform heating.

- Cooling and tearing film: After pressing, wait for cooling for 3-5 seconds and slowly tear off the PET transparent film.

Practical tips

- Use silicone cloth to cover the reflective material to avoid surface scratches.

- If the transfer area is large, it is recommended to use a double-platen heat press to ensure heat balance.

- Low-temperature fabrics need to be tested for high temperature resistance to avoid discoloration or shrinkage of the material.

Common problems and solutions for using heat transfer reflective webbing

Problem 1: The reflective layer falls off or warps

Reason: Insufficient temperature, short pressing time or insufficient pressure

Solution: Check whether the parameters of the heat press machine reach the recommended value, and appropriately extend the pressing time

Problem 2: The reflective brightness is not obvious

Reason: The glass bead layer is damaged or the transfer is incomplete

Solution: Avoid using scratching objects and use a complete and uniform pressing process

Problem 3: Bubbles or wrinkles after transfer

Reason: The fabric is not preheated or the moisture content is too high

Solution: Preheat the fabric and keep it dry

How to choose high-quality heat transfer reflective webbing? Professional advice and judgment criteria

When purchasing heat transfer reflective webbing, it is recommended to evaluate from the following dimensions:

1. Reflective brightness

Visibility is the first standard. High-quality materials reflect clearly after being illuminated in the dark, without graying or color cast. Suppliers can be asked to provide samples and tested separately under natural light and lighting conditions.

2. Washing and dry cleaning fastness

When purchasing, you can find out whether the supplier conducts ISO 6330 (home washing test) or ISO 15797 (industrial washing test), and ask about the number of washes and temperature range that the reflective tape can withstand.

3. Glue uniformity and high temperature resistance

Poor-quality materials may have problems such as uneven glue layer accumulation, yellowing, and aging. It is more reliable to choose reflective tape that does not change color or warp at high temperatures (150°C).

4. Whether it has environmental protection and safety certification

For example, OEKO-TEX Standard 100, REACH, EN ISO 20471 and other certifications can be used as an important basis for quality judgment.

5. Whether it supports customization

For brand customers or high-end customization, whether it supports LOGO printing, pattern customization, and different reflective colors (silver, color, rainbow, luminous) are also key indicators.

Heat transfer reflective webbing is an innovative material that truly combines functionality, safety and design aesthetics. It not only helps users gain higher visibility during nighttime activities, but also provides clothing manufacturers with greater design freedom and production efficiency.

As a professional reflective material for clothing manufacturer like YSM, we are committed to promoting high-performance heat transfer reflective webbing to more industries, helping clothing designers and factory producers find the perfect balance between safety and fashion. I hope the information provided in this article can help you avoid detours in the process of selecting, using, and optimizing heat transfer reflective webbing, and make more efficient and professional decisions.

If you are looking for high-quality reflective materials, please contact us for samples and technical advice to make your products more shining, safe, and excellent.

Related News

Application of Flame Retardant Reflective Tape in Firefighter Equipment

2025-07-18

Application of Glow in the Dark Film in Safety Signage

2025-07-16

Ysmlite:Luminous Film Manufacturer Providing Leading Services

2025-07-15