How to Extend the Service Life of Photoluminescent Film?

2025-05-21

Ysmlite

ysmlite.com

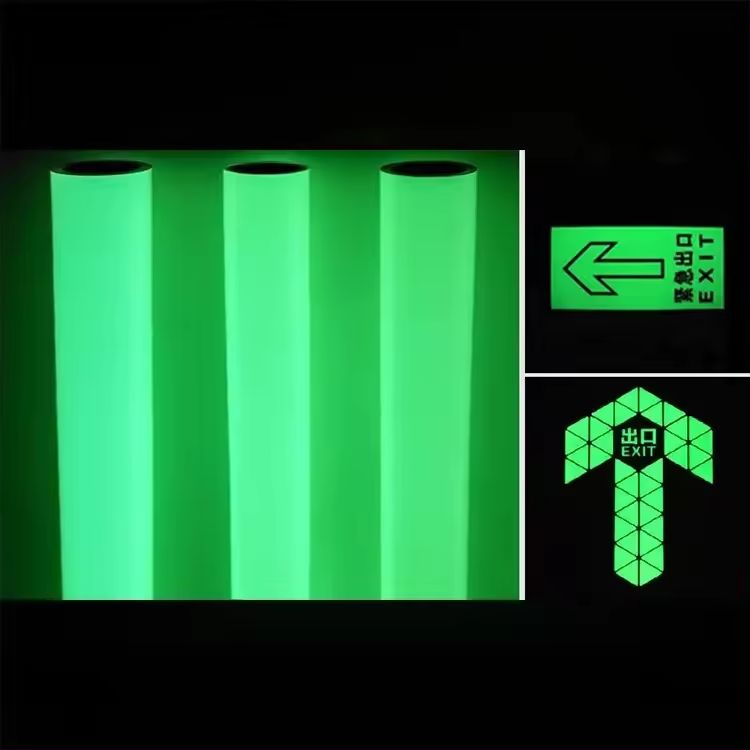

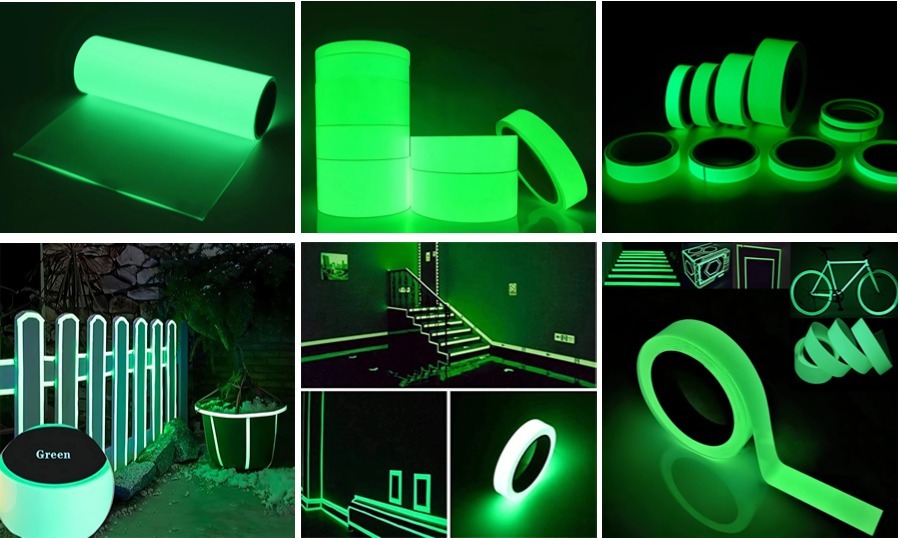

In many scenarios involving safety, warning, decoration and outdoor signs, photoluminescent film is an indispensable material. It can continue to glow in the dark, providing people with visual guidance, and is widely used in reflective clothing signs, building escape systems, traffic signs and consumer product decoration. However, no matter how wide its usage scenarios are, photoluminescent film has an unavoidable reality problem-limited service life.

For purchasers, construction parties and even ordinary consumers, how to make the photoluminescent film play a longer and more stable luminous performance has become a challenge often faced in practical applications. In fact, the premature failure of many luminescent films is often not due to problems with the product quality itself, but due to "human" factors such as improper storage, incorrect use, and environmental incompatibility.

Therefore, Ysmlite will start from the principle of photoluminescent film, deeply analyze the key factors affecting the lifespan, and combine YSM's many years of practical experience as a luminescent film factory to provide readers with an operational life extension strategy. Whether you are a wholesaler, processing plant, construction party or designer, I believe that this practical guide will allow you to master the "core secrets" of luminescent film maintenance, helping you to use it longer, brighter, and more worthwhile!

Basic principles and usage scenarios of photoluminescent film

To extend the service life of luminous film, you first need to understand its "working logic". Photoluminescent film is a material that can absorb light energy and slowly release it in the dark. Its core is a functional layer doped with rare earth luminescent materials (such as strontium aluminate, calcium aluminate, etc.). It absorbs ultraviolet or visible light during the day or under illumination, and then emits green, blue-green or yellow fluorescence in the dark.

Common usage scenarios include:

- Reflective decoration of clothing and backpacks: combined with thermal bonding technology, it is used for outdoor clothing, sportswear, and children's backpacks.

- Building evacuation system: installed on ground guide lines, stair edges, door frames and other locations.

- Traffic signs and equipment: widely used in safety signs in subways, highways, airports and other places.

- Consumer products: children's toys, key chains, night warning decorative strips, etc.

Types of photoluminescent film:

- Self-adhesive luminescent film: There is glue on the back and can be directly pasted.

- Thermal transfer luminescent film: It needs to be transferred to the target surface by hot pressing.

- Spray-type luminescent coating: Luminescent materials exist in the form of coatings and can be sprayed on the surface of various media.

Precisely because of the diverse application scenarios, photoluminescent films face different challenges in actual use, such as frequent washing, sun exposure, friction, high and low temperature changes, and their performance maintenance becomes complicated.

Key factors affecting the life of photoluminescent films

Many people think that luminescent films are "used first", but this is actually a misunderstanding. The performance changes of luminescent films are often not sudden, but an "explosion" after the accumulation of potential factors. Below, we will analyze it in depth from several technical perspectives:

Light source type and exposure time

The efficiency of luminous film in absorbing light energy in different bands varies greatly. For example:

- Natural sunlight (especially afternoon light with rich ultraviolet rays) has high absorption efficiency and fast charging.

- Indoor LED lighting has low absorption efficiency and requires longer exposure time.

- The spectrum of fluorescent lamps has more ultraviolet bands and slightly better effects.

If inefficient light sources are exposed for a long time, the luminous film is prone to "not fully charged", which may reduce its energy storage capacity in the long run.

Ambient humidity and temperature

High humidity environment may cause the luminous film material layer to absorb moisture and expand, affecting its stability; while high temperature environment is likely to accelerate the aging of the film and the decomposition of the luminous material. For example:

- When the temperature is higher than 50℃, some PVC base films may soften and bubble.

- When the relative humidity exceeds 80%, the film material with strong hygroscopicity of the coating may stick or lose viscosity.

Friction and chemical erosion

The fluorescent material on the surface of the luminous film is sensitive to friction, solvent cleaners, and acid-base environments. For example:

- Washing clothes too many times (such as more than 20 times) may significantly reduce the luminous intensity.

- Wiping with solvents such as ketones and alcohols can easily destroy the functional layer structure.

Substrate and processing methods

The use of different substrates (PET, PVC, TPU, etc.) and coating methods (spraying, silk screen, lamination) has a decisive influence on the lifespan. YSM research found that PET substrates have better thermal stability and are suitable for high-temperature hot pressing processes, which can increase the lifespan by 15-20%.

How to protect luminous film during storage and transportation

Even if it is a roll of luminous film with excellent performance, if it is not stored or transported properly, its initial quality may be greatly reduced before it is used. The following are the storage and transportation specifications that YSM factories follow on a daily basis for your reference:

Store away from light to prevent premature "discharge"

It is recommended to store the luminous film in a light-proof, ventilated, and dry environment, and use kraft paper or black plastic bags to package it to avoid unnecessary light causing "premature energy storage" and light decay.

Temperature and humidity control

Recommended environmental conditions are:

- Temperature 10℃~30℃

- Relative humidity 40%~65%

Exceeding this range may cause deformation of the substrate, shedding of the functional layer, decreased viscosity and other problems.

Stacking method

- Do not press horizontally to prevent wrinkles.

- It is recommended to place vertically or use a special tube rack for hanging.

- Do not stack too high to avoid deformation of the bottom under stress.

Reasonable setting of shelf life

YSM recommends that the shelf life of the photoluminescent film be controlled within 12 months. Even if it is not used after the time is exceeded, the luminous intensity needs to be re-tested.

Life extension skills and misunderstandings to avoid during use

Even under the premise of good production conditions and compliant storage environment, the details in actual use directly determine the "final performance" of the luminous film. The following is the "golden rule of life extension" summarized from customer feedback and YSM engineering tests over the years:

Use recommended temperature and pressure for thermal bonding

- Different luminous films are suitable for different temperatures, times and pressures. For example:

- TPU-based luminous film: recommended temperature 150-160℃, time 10 seconds, pressure 3kg/cm²

- PET-based luminous film: recommended temperature 120-130℃, time 12 seconds, pressure 2.5kg/cm²

The "sleeping time" after bonding should be sufficient

It is recommended to wash or stretch the luminous film at least 24 hours after bonding. This period of time is the key to completely fix the adhesive and form a stable bond.

Washing suggestions and misunderstandings

- Recommended hand washing or low-speed machine washing, temperature not exceeding 40℃

- Dry cleaning, bleaching, strong dehydration, and drying machine heating are prohibited

- Use neutral laundry detergent and avoid alkaline detergents

Misunderstandings: Many users think that drying after washing can restore the light performance. In fact, the luminous film does not rely on heat recovery, but relies on light energy to charge.

Try to avoid strong stretching and improper cutting

For some luminous film materials (such as PVC substrates), if they are stretched more than 10% during installation or processing, the coating may crack and the light energy storage capacity may decrease.

Professional advice: selection of suitable materials and optimization of processing technology

Choosing a suitable luminous film can not only increase the actual service life, but also be more conducive to subsequent construction and maintenance. YSM recommends paying attention to the following points when choosing:

Material recommendation

| Application scenario | Recommended substrate | Reason |

| Thermal bonding of clothing | TPU | Soft and washable, good fit |

| Hard sign | PET | Good weather resistance, high thermal stability |

| Ground/staircase indication | PVC | Low cost, easy construction, but requires anti-slip treatment |

Process optimization suggestions

- Adding a base coat: can improve the bonding strength between the film and the bonded surface.

- Adopting electrostatic composite technology: reduce bubbles and improve bonding uniformity.

- Set reasonable bonding parameters and standardize the operation process to avoid quality fluctuations due to differences in operators.

Purchase suggestions

High-quality luminous film should have the following performance parameters:

- Initial luminous brightness (10 minutes): ≥150mcd/m² (according to DIN 67510 standard)

- Luminous duration: ≥8 hours

- Washing durability: ≥20 times

- High and low temperature resistance range: -20℃~+60℃

Cleaning and maintenance: common problems and countermeasures

Improper cleaning methods are a common cause of the decline in the performance of luminous films. The following are maintenance suggestions for different scenarios:

Luminous film for clothing

- Fold the reverse side before washing to effectively protect the luminous area.

- Do not use softener, as it will form a coating and affect the light storage performance.

- It is best to dry it naturally in a cool and ventilated place.

Luminous film for buildings/equipment

- Dust the surface every 3-6 months, and keep it clean to improve the light storage efficiency.

- Use a soft cloth and a neutral detergent, and avoid acid, alkali or alcohol products.

- If the luminous intensity is found to be reduced, it is recommended to replace or re-apply a new film.

Troubleshooting of common problems:

| Problem | Possible causes | Suggestions |

| Luminous intensity weakens | Insufficient light or surface contamination | Check lighting conditions and clean the surface |

| Wrinkles or peeling of film | Poor adhesion or high humidity | Change construction method or improve storage environment |

| Discoloration or loss of luminous effect after washing | Using strong acid/alkaline detergent or dry cleaning | It is recommended to replace mild detergent and avoid dry cleaning |

The charm of photoluminescent film lies not only in the moment when it glows quietly in the dark, but also in the long-term safety and beauty it can bring to people. Extending its service life is not high-tech, but comes from our understanding of material properties and careful care in daily use.

As a professional manufacturer of reflective materials for clothing, YSM has always adhered to the concept of giving equal importance to technological innovation and customer practical experience for many years, and continuously optimized the luminous film material system and construction process. If you are purchasing luminous film or encounter related usage problems, please feel free to contact YSM, we will provide you with the most suitable products and the most professional usage suggestions.

Extending life is not just about making it live longer, but also about making it glow better.

Related News

Top 5 Reflective Webbing Tape Manufacturers in the World

2025-06-06

Top 5 Flame Retardant Reflective Tape Manufacturers in the Industry

2025-06-05

Do You Know the Service Life of Reflective Webbing Tape?

2025-05-27