Top 5 Reflective Material Manufacturers in the Industry

2025-06-23

Ysmlite

ysmlite.com

In modern society, nighttime activities, industrial operations, transportation, and outdoor sports are becoming more frequent, and safety needs are also increasing rapidly. In this context, reflective materials for clothing have gradually entered the public eye and become an indispensable part of various protective equipment and functional clothing. Reflective materials can not only significantly improve visibility and reduce the incidence of accidents, but are also increasingly integrated with fashion, sports and technology, leading the new trend of clothing.

This article will introduce the world's top five manufacturers of reflective materials for clothing in detail, including 3M in the United States, ORAFOL in Germany, YSM and Daoming in China, and Reflexite in the United States. A practical purchasing guide is attached at the end of the article to help you systematically understand the technical parameters, brand advantages and purchase recommendations of reflective materials.

3M (USA): Industry pioneer, technical standard setter

When it comes to reflective materials, 3M is undoubtedly an unavoidable name. This American company has been involved in the research and development of optical reflective materials since 1939. Its Scotchlite series of reflective fabrics are widely used in police, fire, transportation and sports fields around the world.

3M has a large number of core patents in reflective technology, the most representative of which is the micro glass bead reflective technology. By implanting thousands of micro glass beads into a polymer substrate and supplementing it with a metal reflective layer, an excellent retro-reflective effect is formed. Its brightness value (cd/lux·m²) can reach more than 450 in conventional fabrics, which is a high-performance grade in the EN ISO 20471 standard.

In addition, 3M continues to innovate in washability, flexibility and flame retardancy. For example, its high-performance reflective fabric (8712 series) that is resistant to industrial washing can still maintain more than 80% of the reflective effect even after 75 washes. 3M's authority is also reflected in the fact that its reflective materials have almost become a reference benchmark for global industrial protection standards.

When purchasing, users can identify genuine products through packaging labels, anti-counterfeiting watermarks, brightness tests, etc., to avoid counterfeit materials on the market affecting safety.

YSM (China): Asia's leading reflective material manufacturer

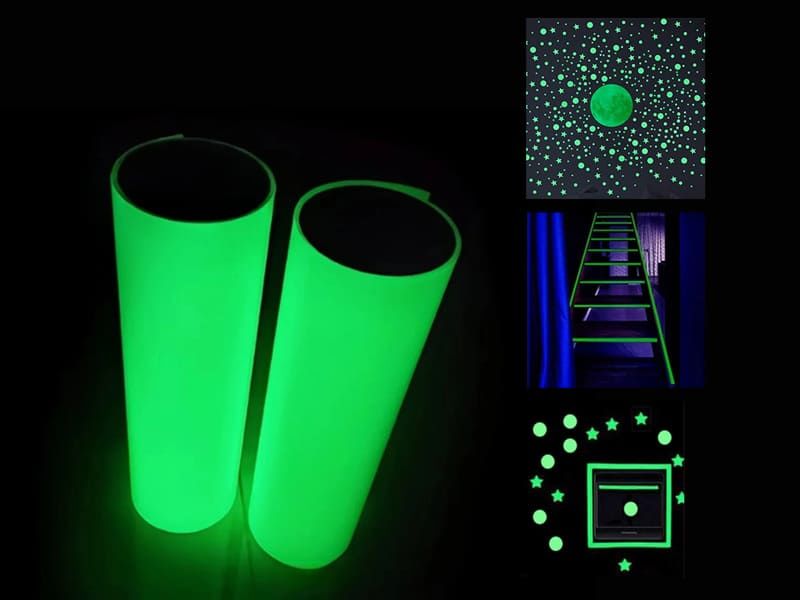

As a pioneer in the field of reflective materials for clothing in China, YSM has become an important brand representative in the Asian market with its deep technical accumulation and international quality system. YSM has multiple automatic coating, lamination, hot-sticking and printing production lines, and its product lines cover dozens of series such as reflective cloth, reflective film, hot-sticking reflective strips, flame-retardant reflective tapes, and luminous reflective composite films.

In terms of technology, YSM focuses on achieving multi-functional integration in material performance, such as launching products with multiple characteristics such as high brightness, flame retardancy, waterproofness, and ironing, which are widely used in firefighting suits, chemical protection suits, sanitation suits, outdoor cycling equipment, children's clothing, and pet clothing. Its flame-retardant series has been verified by standards such as EN469 and NFPA 1971 to ensure safety in extreme environments.

YSM also places special emphasis on customized service capabilities, and can carry out OEM/ODM development in terms of gram weight, width, number of coating layers, printing patterns, etc. according to customer needs. At the same time, its products have obtained multiple international certifications such as OEKO-TEX 100, EN ISO 20471, ANSI 107, CSA, etc., and are qualified to export to North America, Europe, Japan and other markets.

Regarding usage tips, YSM recommends that customers use a hot press to set the temperature to 140160℃, the pressure to 34kg, and the time to 12~15 seconds during the ironing process of the hot-stick reflective film, and use a peeling test paper to confirm the bonding strength.

ORAFOL (Germany): A combination of European technology and global certification system

ORAFOL is a world-renowned manufacturer of optical materials and adhesive products, headquartered in Oranienburg, Germany, and is famous for its ORALITE series of reflective materials. ORAFOL reflective materials are widely used in traffic signs, industrial protection and clothing products, and are also technologically advanced in reflective fabrics.

The significant advantage of ORAFOL products is that they use polymer multilayer structure and high-reflectivity micro-prismatic technology to improve reflective brightness and material durability. Its reflective fabric supports repeated washing and dry cleaning, and has good scratch resistance and wear resistance, especially suitable for police, railway, emergency and aviation clothing.

The brand's products comply with REACH regulations and have obtained international standard certifications such as ISO 9001 and EN ISO 20471, and have outstanding performance in environmental protection and occupational protection specifications.

In terms of purchasing suggestions, users should pay attention to the classification of ORAFOL products (such as OM4000 and OM5000 series). Different series have different brightness values and washability levels, and corresponding materials can be selected according to the usage scenario.

Reflexite (USA): Innovator of micro-prismatic reflective technology

Reflexite was originally an independent company focusing on the development of micro-prismatic reflective technology. It was later acquired by the Orafol Group and became one of its high-end brands. The biggest feature of this brand is that it uses a single-layer micro-prismatic structure, which has higher reflective efficiency and stability than traditional glass bead reflective materials.

Reflexite reflective materials have excellent brightness, especially in long-distance visibility. Its products are widely used in outdoor equipment, cycling clothing, helmets, sports vests and other occasions, emphasizing the advantages of lightness, softness and strong weather resistance.

In addition, Reflexite's product design also fully considers the convenience of processing, such as strong peeling adhesion and heat sealing stability, which can be easily adapted to various fabrics and clothing structures.

The brand enjoys a good reputation among global outdoor brands, racing sports and military equipment, and is suitable for high-end customized customers.

Zhejiang Daoming (China): One of the most fully certified reflective material factories in the world

Zhejiang Daoming Optics is one of the leading companies in the field of reflective materials in China, and one of the manufacturers with the most certification types worldwide. The company's product categories cover reflective cloth, reflective film, reflective strips, thermal film, printed reflective, luminous film and other categories, with a complete process system, from glass bead implantation, coating, compounding to hot melt adhesive in one step.

In terms of export markets, Daoming Optics has reached cooperation with many internationally renowned brands and government projects, including sanitation systems, school uniforms, railway systems and petrochemical fields. Its products have multiple national standard certifications such as EN ISO, ANSI, AS/NZS, CSA, etc., which can meet market access requirements around the world.

Daoming's products pay great attention to detail control, especially emphasizing brightness value control and weight consistency. For example, its high-brightness reflective fabric DM6200 series has a brightness of more than 450cd/m² at a 60° illumination angle, which is suitable for extreme nighttime visibility requirements.

How to choose the right reflective material for clothing? One article answers all questions

Faced with many reflective material brands and products on the market, how do purchasers and designers choose the most suitable material? Here are some practical suggestions:

Clear usage scenarios:

- Industry/construction: Give priority to reflective fabrics with strong flame retardant and washable performance, such as 3M or YSM flame retardant series.

- Children/pets: Soft and non-irritating materials can be selected, such as Daoming flexible series.

- Outdoor sports: Lightweight, high-brightness, breathable micro-prismatic reflective materials such as Reflexite should be used.

What are the key technical parameters to look at?

- Brightness value (cd/lx·㎡): 200 or more is the basic requirement, and more than 400 is the high brightness level.

- Washing times: Conventional laundry requires more than 25 times; industrial use requires more than 75 times.

- Flame retardant performance: whether it meets EN469, NFPA 701 and other standards;

Common misunderstandings:

- Mistakenly use color brightness as a judgment standard.

- Ignore whether the bonding method matches the fabric used.

- Put into large-scale production without testing small batch samples.

Tools and testing suggestions:

- Brightness tester (can measure the reflective angle performance of reflective fabric).

- Ironing heat press (set precise temperature and pressure).

- Peel strength test paper (verify whether the heat paste is firm)

OEM/ODM cooperation process suggestions:

- Confirm proofing (brightness and weight).

- Clarify washing requirements and compliance certificates at the quotation stage.

- After small batch testing, large-scale production will begin.

In summary, the world's top clothing reflective material manufacturers each have their own advantages. 3M is known for its technical standards, ORAFOL takes both craftsmanship and environmental protection into consideration, Reflexite excels at high-performance microprismatic materials, YSM wins the market with its Asian manufacturing advantages and customization capabilities, and Daoming guarantees global exports with a comprehensive product system and authoritative certification.

When purchasing reflective materials, it is recommended to choose a suitable brand based on specific application scenarios, budgets, functional requirements and processing technology. For customers who want to find a stable partner in the mid-to-high-end market, YSM's full-process customization and high-standard compliance capabilities are worthy of special attention.

Clothing reflective materials are not just an accessory, but also about life safety and brand responsibility. I hope this article can provide clear guidance and confidence support for your material selection and procurement.

Related News

Application of Reflective Fabric Tape for Outdoor Use

2025-08-08

Application of Luminous Film in Home Decoration

2025-08-08

The Role of Flame Retardant Reflective Tape in Wildfire Rescue

2025-08-05