Flame Retardant Reflective Tape Certified by NFPA2112 and NFPA1971

2025-06-17

Ysmlite

ysmlite.com

In industrial safety and high-risk operation scenarios, such as fire rescue, petrochemical, metal smelting and other fields, the protective equipment worn by practitioners determines their life and death. As a key component of these equipment, reflective materials not only carry the function of night visibility, but also must have resistance to harsh environments such as high temperature, flame, wear, and oil. In recent years, flame-retardant reflective tapes have surged in demand in the global market due to their dual properties - flame retardant and reflective. Certification is the core standard for judging whether such materials are truly safe and reliable.

Among all certification systems, the NFPA2112 and NFPA1971 standards issued by the National Fire Protection Association (NFPA) of the United States have extremely high international authority. These two standards focus on industrial flame-retardant clothing and fire protection equipment respectively. Whether they can pass their rigorous tests directly determines whether reflective materials have a pass to enter the high-end market. For reflective material manufacturers, obtaining these two certifications is not only a reflection of product technical strength, but also the best endorsement of customer safety commitments. As a brand focusing on the research and development and manufacturing of reflective materials, YSM is well aware of the importance of certification. After more than ten years of continuous iteration of materials and optimization of processes, it has finally successfully obtained these two certifications and continues to provide high-standard flame-retardant reflective tapes to global customers.

Detailed explanation of NFPA2112 and NFPA1971 standards

NFPA2112: Core standard for industrial flame-retardant clothing

The NFPA2112 standard is formulated by the National Fire Protection Association of the United States and is mainly applicable to work clothing and accessory materials in high-temperature explosion risk industries such as petroleum, natural gas, and chemicals. It is extremely strict in testing flame-retardant materials, mainly including:

- Vertical Flame Test: Test whether the extinguishing time of the sample under the action of open flame is within 2 seconds, and the carbonization length shall not exceed 102mm.

- Thermal Protective Performance Test (TPP): Measures the thermal insulation effect of the material on the human body under the action of heat flow.

- Heat Shrinkage Test: Heated at 260°C for 5 minutes, the material cannot shrink or deform significantly.

Washability: The sample must remain flame retardant after 100 industrial washes.

NFPA1971: Standard for firefighter protective equipment

NFPA1971 is specifically for personal protective equipment used by structural firefighters and emergency responders, including clothing, helmets, gloves, boots, and accessory materials used (such as reflective strips). This standard is more stringent than NFPA2112 and adds the following items:

- Overall Thermal Protective Performance: The entire set of equipment is required to protect the skin from burns in a simulated high temperature environment.

- Burst strength test: The reflective material must withstand high pressure and tearing.

- Light reflection stability: After being affected by high temperature, humidity, washing, etc., the reflective effect remains stable.

- Smoke toxicity test: No toxic gases shall be released in the burning state.

The common point of the two standards is that they emphasize that the material must have true flame retardant ability and remain stable after multiple uses and washing; but they serve different objects, one is biased towards industry and the other is for fire protection, and the certification path should be selected according to the actual application.

What does certification mean for flame-retardant reflective tape products?

Technical level: extremely high requirements for structural performance

In order for flame retardant reflective tape to meet NFPA2112 and 1971 certification, special design must be made in the material structure. Generally include:

- Use aramid or other intrinsically flame-retardant fibers as the base fabric, which is not easy to melt.

- The reflective layer uses microprisms or high-purity glass beads, and does not fall off at high temperatures.

- The adhesive process needs to be stable and heat-resistant, without delamination or bubbles.

Quality control level: continuous consistency certification is the key

Obtaining certification is only the first step, and maintaining product consistency is a long-term challenge. NFPA certification not only inspects samples, but also requires annual re-inspection, factory sampling, and production process filing. YSM ensures that each batch of products shipped is consistent with the samples sent for inspection and maintains brand reputation by building a digital quality monitoring system.

Market level: a pass to obtain international orders

Especially in the high-standard markets of Europe and the United States, passing NFPA certification means that the product can be directly used in the production of fire uniforms and industrial protective equipment, which is the basic entry condition for many buyers. At the same time, certification can also enhance customer trust, increase price space, and form a brand barrier.

How to determine whether your flame retardant reflective tape meets these two standards?

Practical tips: Check the certification mark and number

- Check whether the product comes with a UL certification number (such as E123456) and is marked with "Meets NFPA 2112" or "NFPA 1971 Compliant".

- Check whether there is an official test report issued by SGS, Intertek or UL.

- Check the NFPA official website or UL official database to verify the authenticity of the certificate.

Customer advice: Identify fake certifications

Some manufacturers in the market forge NFPA compliance marks, especially in low-priced reflective materials. Be wary of the following points when purchasing:

- The price is much lower than the market price.

- There is no original certification report or PDF without watermark.

- The product has no laser anti-counterfeiting mark.

YSM comes with a test report QR code and certification number in each batch of product packaging. Customers can scan the code to verify and ensure that each batch of products is compliant and reliable.

How YSM passed the dual standard certification: the whole process from R&D to manufacturing

Material selection: safety performance is the first principle

YSM uses imported flame-retardant aramid and PBI blended fabric as the base material, which has a higher flame retardant grade than conventional polyester fabric. The reflective layer adopts the self-developed multi-layer vacuum evaporation glass bead technology, which not only has high reflective brightness, but also does not fall off or turn yellow under heat.

Process flow control

- Hot pressing composite process: high temperature composite at above 150°C to ensure firm bonding between layers.

- Reflective layer stabilization treatment: adding ultraviolet curing agent to improve weather resistance.

- Back adhesive reinforcement technology: through microporous penetration of the adhesive layer, the tape can still adhere stably after multiple lamination and tearing.

Self-test system is perfect

YSM has an independent laboratory equipped with thermal protection performance TPP tester, flame-limiting vertical combustion device, washability simulator and other equipment to conduct routine tests on each batch of products. All products shipped must pass internal tests that are more stringent than NFPA standards before they can be shipped.

Case display: Providing certified customized solutions for global customers

- A US fire suit brand specifies the use of YSM NFPA1971 certified tape.

- A European chemical group purchases YSM NFPA2112 certified tape for hazardous work clothing.

- OEM customers customize flame-retardant reflective tapes with special colors and patterns, and still pass NFPA tests.

Applicable industry case analysis: actual performance of certified tapes in different industries

Fire suit field

Certified tapes can maintain reflective brightness and structural integrity in high temperature environments above 800°C, and are an indispensable key material for fire suits. YSM products pass melting point tests and maintain their original performance after repeated washing.

Petrochemical industry

There are a large number of flammable gases and liquids in the industry. YSM flame retardant tapes have multiple properties such as oil resistance, acid and alkali resistance, and UV aging resistance, and have passed IEC 61482 arc protection test.

High-risk work uniforms

Such as railway maintenance, power maintenance, airport ground handling, etc., certified tapes provide 360-degree visibility at night to reduce the risk of personnel being accidentally injured by machinery.

Actual customer feedback

According to customer feedback, YSM NFPA certified tapes perform stably in on-site clothing use. Even after 60 industrial washes, there is no blistering, shedding, or darkening of the reflective surface, and it is widely praised.

The value of flame-retardant reflective tapes is never just reflected in the reflective appearance or basic flame retardancy, but whether it can truly protect the safety of the wearer at a critical moment. NFPA2112 and NFPA1971 are currently internationally recognized high-standard certification systems, and only a very small number of manufacturers can actually pass all tests.

As a professional reflective material manufacturer with actual certification, YSM can not only provide customers with compliant products, but is also willing to provide technical support and material selection suggestions to help you achieve the best balance between safety and performance. Choosing YSM is choosing a guarantee that is responsible for life.

Related News

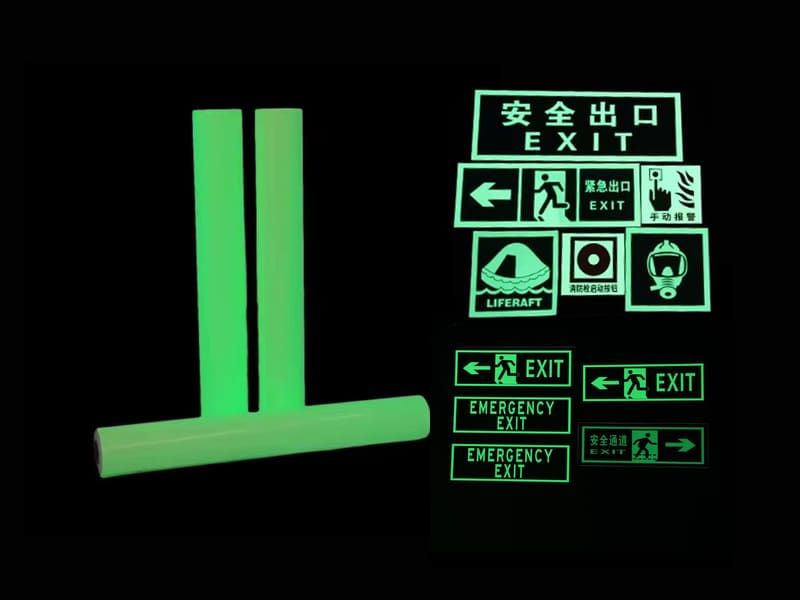

Application of Luminous Film in Maritime Safety Signage

2025-08-01

Application of Flame Retardant Reflective Tape in Safety Apparel

2025-07-31

Application of Flame Retardant Reflective Tape in Traffic

2025-07-29